A wind turbine is an electrical device that converts wind energy into mechanical work, which drives the rotor to rotate and ultimately outputs alternating current. Wind turbines generally consist of components such as wind turbines, generators (including devices), directional controllers (tail fins), towers, speed limiting safety mechanisms, and energy storage devices.

Wind power tower equipment is usually installed on high towers. The higher the ground and the higher the wind speed, the easier it is for wind turbines to be driven to generate electricity.

The working principle of wind turbines is relatively simple. The wind wheel rotates under the action of the wind, converting the kinetic energy of the wind into the mechanical energy of the wind wheel shaft. The generator rotates to generate electricity driven by the wind turbine shaft.

Broadly speaking, wind energy is also solar energy. So, it can also be said that a wind turbine is a type of thermal energy utilization generator that uses the sun as the heat source and the atmosphere as the working medium.

Wind power utilizes natural energy. Compared to diesel power generation, it is much better. But if it is used for emergency, it is not as good as diesel generator. Wind power cannot be considered as a backup power source, but it can be utilized for a long time.

The principle of wind power generation is to use wind power to drive the blades of a windmill to rotate, and then increase the speed of rotation through a booster engine to drive the generator to generate electricity. According to current wind turbine technology, a gentle wind speed of approximately three meters per second (the degree of gentle wind) can start generating electricity.

Wind power generation is very popular in countries such as Finland and Denmark; China is also vigorously promoting it in the western region. Wind power generation is forming a trend around the world because it does not have fuel issues, nor does it generate radiation or air pollution.

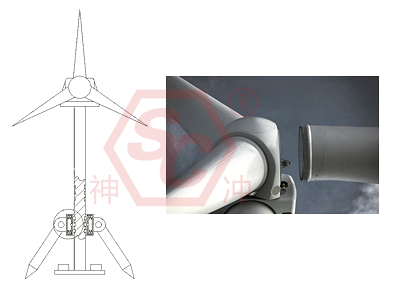

Most existing wind turbine towers are designed as simple tubular or lattice tower structures. The higher the installation of wind turbines, the better. Most wind turbine towers are built very high.

However, ordinary wind power towers have a weak ability to withstand wind loads and are prone to plastic deformation after use for a period of time, which affects the power generation of wind turbines. Therefore, wind turbines need to be manufactured and processed with high-quality materials and equipment. For example, a Upper Roller Universal Three-roller Bending Roll can be used.

The cabin contains the key equipment of the wind turbine, including the gearbox and generator. Maintenance personnel can enter the engine room through the wind turbine tower. On the left end of the cabin is the wind turbine rotor, which includes the rotor blades and shaft.

The rotor blades capture the wind and transmit it to the rotor axis. On modern 600 kW wind turbines, the measured length of each rotor blade is approximately 20 meters and is designed to resemble the wings of an airplane.

The rotor axis is attached to the low-speed shaft of the wind turbine.

The low-speed shaft of a wind turbine connects the rotor shaft to the gearbox. On modern 600 kilowatt wind turbines, the rotor speed is quite slow, approximately 19 to 30 revolutions per minute. There is a conduit in the shaft for the hydraulic system to activate the operation of the aerodynamic brake.

On the left side of the gearbox is the low-speed shaft. It can increase the speed of the high-speed shaft to 50 times that of the low-speed shaft.

The high-speed shaft operates at 1500 revolutions per minute and drives the generator. It is equipped with emergency mechanical brakes for use in the event of aerodynamic brake failure or when wind turbines are being repaired.

Generators are commonly referred to as induction motors or asynchronous generators. On modern wind turbines, the maximum power output is usually 500 to 1500 kilowatts.

The yaw device uses an electric motor to rotate the engine compartment to make the rotor face the wind. The yaw device is operated by an electronic controller, which can sense the direction of the wind through a wind vane. Usually, when the wind changes its direction, the wind turbine will only deflect a few degrees at a time.

The electronic controller includes a computer that continuously monitors the status of the wind turbine and controls the yaw device. To prevent any malfunction (i.e. overheating of the gearbox or generator), the controller can automatically stop the rotation of the wind turbine and call the wind turbine operator through a telephone modem.

The hydraulic system is used to reset the aerodynamic brake of the wind turbine.

The cooling element includes a fan for cooling the generator. In addition, it includes an oil cooling element for cooling the oil in the gearbox. Some wind turbines have water-cooled generators.

The wind power tower carries the engine room and rotor. Usually tall towers have advantages because the higher the ground, the higher the wind speed. The tower height of modern 600 kW wind turbines ranges from 40 to 60 meters. It can be a tubular tower or a lattice tower.

A tubular tower is safer for maintenance personnel as they can reach the top of the tower through an internal ladder. The advantage of a lattice shaped tower is that it is relatively cheap.

Anemometer and wind vane are used to measure wind speed and direction.

The tail rudder is commonly used in small wind turbines (usually 10KW and below) in the upwind direction of the horizontal axis. Located behind the rotating body and connected to the rotating body.

The main function is to adjust the direction of rotation of the fan, so that the fan is facing the wind direction. The second function is to make the wind turbine head deviate from the wind direction in strong wind conditions, in order to reduce the speed and protect the wind turbine.

The wind turbine tower is the tower pole for wind power generation. In wind turbines, they mainly play a supporting role while absorbing the vibration of the unit.

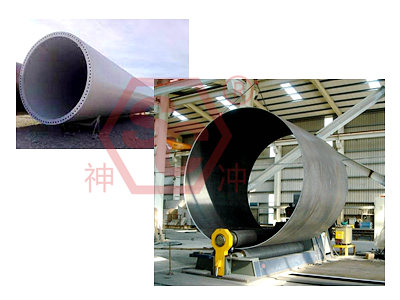

At present, most of the towers for large wind turbines with a capacity of over 100 kilowatts both domestically and internationally use steel cylinders, cones, and cylindrical towers that combine cylinders and cones.

The cylinder plate mainly uses high-quality, hot-rolled low alloy high-strength structural steel. The connecting flanges are all integrally forged. To manufacture and process workpieces of this shape, we need to use a plate rolling machine and cone rolling machine.

Raw materials enter the factory and inspect the materials. Retest the steel plate. Pretreatment: CNC plate shearing, blanking, size inspection. Groove. Processing rolling group. Welding longitudinal seam calibration circle.

Incoming inspection of finished flanges and retesting of test pieces. Flatness inspection of cylinder assembly welding. Secondary processing of the upper surface of the flange (in case of flatness exceeding the standard).

Incoming inspection of finished flanges and retesting of test pieces. Flatness inspection of cylinder assembly welding.

Inspection and welding of each cylinder section and flange assembly. Mark the position line of the interior components. Inspect and weld the internal components for anti-corrosion treatment. Assemble, package and ship.