The full name of security door is "anti-theft safety door". It combines anti-theft and security performance. And the lock used on the security door must be a special anti-theft door lock with anti drilling function that has been tested and qualified by the Testing Center of the Ministry of Public Security.

The anti-theft security door can be made of different materials. But only doors that meet the standard and pass the inspection, and obtain a safety and protection product production permit, can be called anti-theft doors. At present, the most mainstream security doors on the market are mainly made of a series of processes such as cold rolled steel plate bending and welding, with a small portion made of zinc iron alloy.

Reliable door manufacturers will adopt high quality processing machinery to production workpieces. Wuxi Shenchong press brakes are always adopted in security door industry. Welcome to consult! Firstly, we need to know which parts the general process is divided into.

Material selection - cutting - door core cutting - punching - bending - welding - bonding - polishing - framing - cold pressing - edge trimming and fine cutting - gluing - door leaf stitching - rough grinding - first base - polishing - second base - polishing - third base - polishing - color repair - polishing - topcoat

Select facade materials according to customer requirements.

The facade is embossed according to the customer's requirements.

According to the customer's requirements, use a CNC shearing machine to cut the board into suitable sizes for accurate operation in the next process.

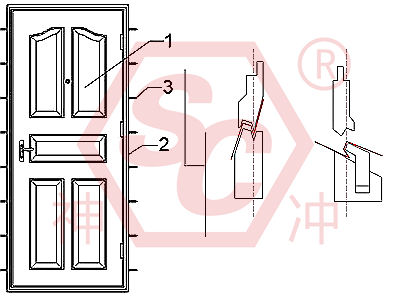

Accurately complete the following tasks using a CNC punching machine: punching angle, punching handle hole, punching door bell hole, punching edge lock hole, punching cat eye hole, ensuring the product's fit size. The main lock hole, side lock hole, expansion screw hole, lock fork hole, and assembly line hook hole of the gantry are completed.

Using a CNC press brake machine equipped with precision bending molds for multi pass bending processing of door surfaces and frames.

For better bending, some factory will use v grooving machine before bending. In this way, the bent door panel will be more beautiful and precise.

Some manufacturers even use robot bending units to save labor and improve efficiency. The production and processing of such anti-theft door manufacturers will be more advanced and intelligent.

Weld the small components that need to be installed in advance on the door surface, such as hinge fixing plates, upper and lower sealing plates, and main lock boxes.

Soak the door leaf and frame for a total of about 30 minutes before entering the next process, ensuring that the surface of the steel plate is cleaned of acidic embroidering substances. And apply a layer of phosphating film to facilitate the adhesion of the plastic powder in the future spraying process.

After filling the middle part of the front and rear door panels with honeycomb paper or fireproof cotton for welding, the door surface is fastened and shaped using a hydraulic equipment hot bonding machine to make the door surface flat and not deformed.

The special treatment process for the facade ensures the beauty of the color and wood grain of the facade. The paint spraying workshop requires multiple processes such as primer painting, water washing, drying, wood grain heat transfer printing, and oil drying treatment for the door surface.

To solve the problem of fading caused by strong ultraviolet light irradiation on steel doors, it is necessary to increase the surface's anti fading ability.

Use the hinges to assemble the door frame and door frame together. At the same time, install other things such as cat eyes, doorbells, lock cylinders, and leather strips.

The above is the general production process of the security door. As a professional and reliable door and window manufacturer, manufacturers should choose high-precision and high-performance production and processing equipment to meet the needs of different customers.

- The surface of the door frame and door leaf components should be smooth and clean, without obvious dents and mechanical damage.

- The nameplate mark should be correct, firm and clear.

- The anti-theft safety door should have a permanent anti-theft safety level mark.

- The material of the board can be steel, stainless steel, steel/wood, copper or other composite materials.

- Steel plate thickness

The door frame should be selected as 2.00mm, 1.80mm, and 1.50mm according to the anti-theft security level.

The thickness of the outer and inner panels of the door leaf is expressed in the form of "outer/inner". According to the anti-theft safety level, they should be selected as 1.00mm/1.00mm, 0.80mm/0.80mm, and 0.80mm/0.60mm respectively.

The security door is mainly divided into five types in terms of material: steel, steel wood structure, stainless steel, aluminum alloy, and copper. They have their own characteristics in terms of quality and performance, and their natural prices also vary.

When most people choose security doors nowadays, they not only need to have a very good anti-theft effect, but also hope to play a decorative role. Facing so many types of security doors in the building materials market, what material is the best?

Steel security doors are the most common and commonly used type in the market. Most of the familiar anti-theft doors belong to this series. The anti-theft door with steel as the main material, a door frame steel plate thickness of over 2mm, and a door panel thickness of over 20mm, usually weighs more than 40kg.

This type of door is affordable. Its sales account for over 90% of the total market sales. The disadvantage of this type of door is its hard exterior line and poor decorative quality due to its single color. It is difficult to integrate with modern interior decoration.

This is a type of door that can be used for indoor decoration and can generally be requested by the user. The steel and wood anti-theft door is made of wooden pieces wrapped in steel plates, and the steel plate in the middle plays a role in anti-theft.

Manufacturers can choose different colors, wood, lines, and patterns to integrate with indoor decoration according to user requirements. The decoration effect is good. No longer as cold and uncoordinated as steel doors. Therefore, its price is also more expensive than steel anti-theft doors. And after the impact, there will be pit marks left on the door panel.

Stainless steel security doors are made of 201 or 304 aluminum alloy. The thickness of the steel plate shall not be less than 20mm. The thickness of the front and rear door leaves is between 8-10mm. The surface is decorated with different metal colors and patterns. The texture is sturdy and durable, with higher safety.

There are many colors for stainless steel anti-theft doors in the market, including silver white, yellow titanium, rose gold, red titanium, black titanium, rose red, and other colors, as well as stamped flower patterns. The pattern of general steel anti-theft doors can generally be achieved on stainless steel doors. The prices of stainless steel doors in the market vary depending on the materials used.

Copper anti-theft doors are generally integrated with entrance doors. Advanced style. Outstanding performance in fire prevention, corrosion prevention, prying prevention, and dust prevention.

In terms of material, copper anti-theft doors are the best. In terms of price, it is also the most expensive. It is mainly used for financial institutions such as banks or high-end residential villas.

The aluminum alloy material used for this door is different from the ordinary aluminum alloy doors and windows we see. It has a high hardness and a bright color. The surface has patterned patterns, giving a feeling of resplendence. It is a mid range anti-theft door. It is not easy to fade and corrode, so it also has a certain consumer group

But some aluminum alloy anti-theft door hinges use pull nails and cannot be disassembled, and opening and closing doors will make a sound of metal friction.

Firstly, the seller is required to present the relevant department's "Certificate of Conformity".

Secondly, remove the cat's eye, doorbell box, or lock handle and inspect the internal structure of the door body. There should be several reinforced steel bars inside the door to organically connect the front and rear panels of the door. It is best to have asbestos and other materials with fire, insulation, and sound insulation functions as fillers inside the door.

Thirdly, check whether the lock is equipped with anti-theft specialized locks that have been tested and qualified by the public security department, and whether there is reinforced steel plate for protection at the installation location of the lock.

Fourth, check the process quality of products and whether there are welding defect. Whether the fit between the door leaf and the door frame is dense, etc.

Fifth, weigh the weight of the anti-theft door. The weight of a regular anti-theft door shall not be less than 40 kilograms.

Professional door manufacturers will adopt high quality processing machinery to production workpieces, such as muti-axis CNC press brake, CNC V grooving machine and high preicsion shearing machines. Wuxi Shenchong Machines are always adopted in door manufacturing industry. Welcome to consult!