Customization of aluminum alloy doors and windows provides users and manufacturers with efficient, safe, and more affordable door and window options. So what are the manufacturing processes for aluminum alloy doors and windows? How should aluminum alloy door and window panels of various thicknesses be bent?

Aluminum alloy doors and windows are made from surface treated profiles through processes such as cutting, bending, punching, and milling to form door and window frame components. Then it is assembled together with connectors, seals, and opening and closing hardware components.

Processing process: cutting, bending, drilling, assembly, packaging. Specifically, it should be customized according to the window specifications of the house. Then prepare to install the corresponding materials, tools and hardware accessories.

So what are the production process steps for aluminum alloy doors and windows? Let's take a look below.

Cutting sheet metal is the first and key process in the production of aluminum alloy doors and windows. This step mainly uses cutting equipment. The material length is determined based on design requirements and referring to the construction drawings of doors and windows.

Accurate cutting is required. Otherwise, it is difficult to ensure the squareness of the doors and windows. The size error value should be controlled within a range of 2mm.

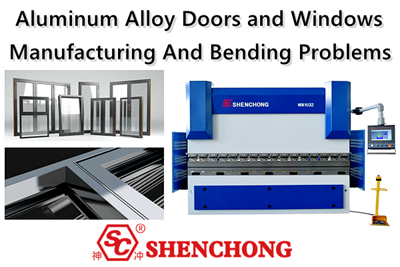

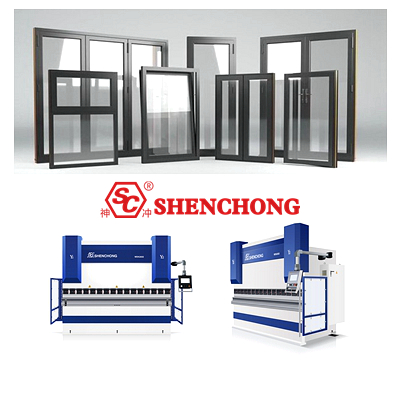

The next step is to bend the cut board according to the design drawings of the doors and windows. We need to use a bending machine in this step. Just choose a press brake with the appropriate tonnage size based on the width and thickness of the sheet metal. Wuxi Shenchong CNC hydraulic press brake machine can be used for processing aluminum alloy doors and windows. Various door and window manufacturers will purchase from us, welcome to consult!

The frame and leaf assembly of aluminum alloy doors and windows generally adopts screw connections. Therefore, whether it is the assembly of horizontal and vertical members or the fixation of accessories, it is necessary to drill holes in the corresponding positions. Small table drills or electric drills can be used for drilling profiles.

According to the requirements of the construction drawing, the profiles are connected and assembled by connecting pieces with screws.

There are three assembly methods for aluminum alloy doors and windows: 45 ° angle docking, right angle docking, and vertical docking. The connection of horizontal and vertical poles generally adopts dedicated connectors or aluminum angles, and is fixed with screws, bolts, or aluminum rivets.

Recently, customers in the aluminum alloy door and window manufacturing industry often ask about aluminum bending when purchasing equipment.

For example:

- What is the coefficient when bending 3mm aluminum alloy doors and windows?

- What is the bending coefficient of 5mm thick aluminum alloy doors and windows?

- Why do aluminum alloy doors and windows crack when bent?

- What molds should be used for bending doors and windows? ......

In fact, the bending coefficient of aluminum alloy doors and windows is regular. Generally, it is 0.8 times the thickness of the aluminum plate.

For example, the bending coefficient of 3mm aluminum alloy doors and windows is 2.4. The bending coefficient of 5mm aluminum plate is 4.

It is generally better to use a 30-degree sharp punch. When using a straight punch with too much pressure, the aluminum plate is prone to cracking.

- The bent edge is parallel to the rolling direction of the aluminum plate, which is prone to cracking. We should turn the bending direction 90 degrees.

- The 180 degree bending angle is too many and should be greater than the minimum bending radius. Generally, the bending radius is 1.5 times the thickness of the plate.

- The reason for the material. Aluminum alloy has better toughness than pure aluminum aluminum plate and is prone to cracking.

- The thickness of the plate is too thick, and bending 180 degrees exceeds the material's bending limit.

The specific issue still depends on the thickness of the aluminum alloy doors and windows you process, the bending drawings, and the bending equipment used. Of course, choosing a press brake with appropriate tonnage and good quality, combined with correct punch and die and operations, will improve the bending effect of door and window workpieces!