We usually receive inquiries from customers, and one of the questions that makes it difficult for us to answer immediately is "I am building a new factory, but what machines do I need to purchase for my workshop?". This is a common question people have when they are just starting out on their manufacturing journey. Whether they're a brand new company, or just starting out with a new product for the first time, they always need to think about “what machinery I need for my factory”. The answer of course totally depends on what you want to produce...

We deal with a wide variety of customers, from specialized manufacturers and suppliers of custom finished products, all the way to workshops of machined parts accessories. The mechanical needs of these customers can vary widely. So it's hard to pick one size that fits all setups. Build your own manufacturing workshop and make everything from gates, railings, cabinets, light poles, and more. Customers think about what sheet metal machines they would need to purchase to start the process. We will put together a guide to the key equipment you may need.

Cut to Length

Slitting Machine Line

Laser Cutting Machine

Guillotine Shear

V Grooving Machine

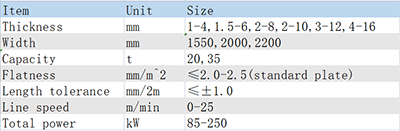

Cut to Length

Cut to Length line is mainly composed of feeding trolley, uncoiler, leveling machine, feeding mechanism, plate shearing machine, conveying device, stacking device and so on. A slitting machine can be configured in the production line to cut the sheet into the required width, cut to length and stack it. It is a high-performance product integrating machine, electricity and hydraulics.

High degree of automation, simple and reliable operation.

High precision of fixed length, high sheet flatness, neat stacking

1. According to the plate thickness, it can be divided into thin plate transverse shear line (processing thickness 0.1-3.0mm) and thick plate transverse shear line (processing thickness 3.0-6.0mm).

2. According to the material of slitting metal, it can be divided into copper strip cutting line, stainless steel cutting line, cold plate cutting line, silicon steel cutting line and tinplate cutting line.

3. According to the degree of automation, it can be divided into automatic cross-cutting line and semi-automatic cross-cutting line.

The cross cutting line is used to uncoil, level, cut to length, cut metal coils into flat sheets of required length and stack them. It is suitable for processing cold-rolled and hot-rolled carbon steel, silicon steel, tinplate, stainless steel and various metal materials after surface coating and cutting to length.

Widely used in metal sheet processing industries such as automobiles, home appliances, food, packaging, decorative building materials, etc.

The slitting line is also called slitting unit, slitting machine, strip cutting machine, and scissors. It is mainly used for slitting and cutting coil materials such as tinplate, galvanized iron, silicon steel sheet, cold-rolled strip steel, stainless steel strip, aluminum strip, and steel strip. It cuts metal coils into strips of various widths, and then harvests the strips into small rolls for the next process. It is a necessary equipment for precision cutting of transformers, motor industries and other metal strips.

Loading trolley feeding -- Upper uncoiler uncoiling -- Outfeed rack -- Uncoiling storage pit -- Circular shear machine slitting -- Scrap edge collection mechanism -- Transition frame --- Tension mechanism -- Rewinder -- Unloading trolley -- hydraulic components -- electrical control system -- pneumatic components.

1. According to the thickness of the slitting plate, slitting machine can be divided into thin plate slitting line (processing thickness 0.1-3.0mm) and thick plate slitting line (processing thickness 3.0-6.0mm).

2. According to the material of slitting metal, it can be divided into copper strip slitting line, stainless steel slitting line, cold plate slitting line, silicon steel slitting line and tinplate slitting line.

3. According to the degree of automation, it can be divided into automatic slitting line and semi-automatic slitting line.

Generally speaking, slitting lines are non-standard products, which are designed and manufactured according to customer requirements.

Used for processing high-speed guardrail, channel steel, section steel, water tank

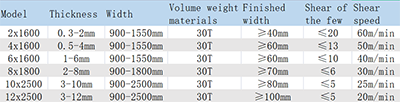

Laser cutting process more and more replaces the traditional mechanical cutting machine in the sheet metal processing industry. Laser cutting machine has the characteristics of high precision, fast cutting, not limited to cutting patterns, automatic typesetting saves materials, smooth incision, and low processing cost. It will gradually improve or replace the traditional mechanical cutting machine. The mechanical part of the laser cutter head has no contact with the workpiece, and will not scratch the surface of the workpiece during work; the laser cutting speed is fast, the incision is smooth and flat, and generally no subsequent processing is required; the cutting heat-affected zone is small, the deformation of the plate is small, and the kerf is narrow ( 0.1mm~0.3mm); high processing precision, good repeatability, no damage to the material surface; the most important is its CNC programming function, can process any shape, and can cut the whole board with a large format without opening molds is economical and time-saving.

1. First of all, you must figure out the production scope, processing materials and cutting thickness of your products, so as to determine the model and quantity of the machines to be purchased, and make a simple foundation for the later procurement work.

Laser cutting machine applications involve mobile phones, computers, sheet metal processing, metal processing, electronics, printing, packaging, leather, clothing, industrial fabrics, advertising, crafts, furniture, decoration, medical equipment and many other industries. The mainstream models on the market are 3015, 4020, 6020 that is, 3 meters by 1.5 meters and 4 meters by 2 meters, and 6 meters by 2 meters. Generally, companies will provide a variety of models for customers to choose from, and laser cutting machine can also be customized.

2. Professionals conduct on-site simulation solutions or provide solutions, and can also take their own materials to the manufacturer for proofing.

1) Fine cutting kerf: the laser cutting kerf is generally 0.10mm-0.20mm;

2) Smooth cutting surface: Whether the cutting surface of laser cutting has burrs or not; generally speaking, the laser cutting machine has a little burrs, which is mainly determined by the cutting thickness and the gas used. Generally, there are no burrs below 3mm. The gas is nitrogen for the best effect, followed by oxygen, and air for the worst effect. The fiber laser cutting machine has minimal or no burrs, the cutting surface is very smooth, and the speed is also very fast.

3) Look at the deformation of the material: the deformation of the material is very small.

4) The size of the power: For example, most factories cut metal sheets below 6mm, so there is no need to buy a high-power laser cutting machine. A 500W fiber laser cutting machine can meet the production needs. If the production volume is large, worry about the 500W efficiency It is not as good as a high-power laser cutting machine. The best choice is to buy two or more small and medium-power laser cutting machines, which will help manufacturers in controlling costs and improving efficiency.

5) The core part of laser cutting: whether the laser and laser head are imported or domestic. Imported lasers generally use more IPG, and domestic ones generally use Raycus. At the same time, other accessories for laser cutting must also be Pay attention, such as whether the motor is an imported servo motor, guide rail, bed, etc., because they affect the cutting accuracy of the machine to a certain extent. One thing to pay special attention to is the cooling system of the laser cutting machine - the cooling cabinet. Many companies directly use household air conditioners for cooling. In fact, everyone knows the effect, which is very bad. The best way is to use industrial air conditioners, which are dedicated to special machines. , to achieve the best results.

3. Any set of equipment will be damaged to varying degrees during use, so in terms of repairs after damage, whether the repairs are timely and the cost of repairs has become a problem that needs to be considered. Therefore, when purchasing, it is necessary to understand the after-sales service of the company through various channels, such as whether the maintenance fee is reasonable and so on.

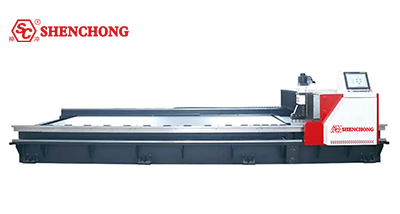

Shearing machine is a machine that uses one blade to make a reciprocating linear motion relative to the other blade to shear the plate. It uses the moving upper blade and the fixed lower blade to apply shearing force to metal sheets of various thicknesses with a reasonable blade gap, so that the sheets are broken and separated according to the required size. The sheet metal shearing machine is a kind of forging machinery, and its main function is the metal processing industry. The products are widely used in aviation, light industry, metallurgy, chemical industry, construction, shipbuilding, automobile, electric power, electrical appliances, decoration and other industries to provide the required special machinery and complete sets of equipment.

Nowadays, due to the popular of laser cutting machine, the plate shearing machine market is decreasing. However, metal shearing machine still have its own irreplaceable advantages compared with laser cutting machine.

lWhen you need high speed cutting straightly on the sheet metal plate, plate shearing machine is still the best choice.

lWhen the next step is laser tailor welding, the cross-sectional stress of the cut plate needs to be smaller and the cutting precision need to be higher, CNC guillotine shear is the better choice than the laser cutting machine.

Guillotine shearing machine adopts a frame structure with all-steel welding; four-corner and eight-sided right-angle guide rails, high precision, good rigidity, and hydraulic preloading. The hydraulic system adopts two-way plug-in integrated valve; the whole system adopts; and can be configured with digital display of stroke, photoelectric protection device and mobile workbench (convenient for mold replacement). Function, the working pressure stroke can be adjusted within the specified range according to the process requirements, and the operation is simple and centralized control by buttons.

Cutting Thickness: 4-40mm

Cutting Length: 2000-6000mm

- Cutting linear accuracy: ±0.03mm

- Back gauge speed: 300mm/s

- Back gauge repeat positioning accuracy: ±0.02mm

- Back gauge optional positioning accuracy: ±0.05mm

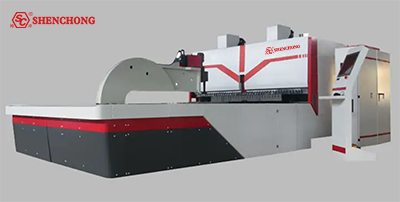

SHENCHONG CNC front feeding guillotine shearing machine use the DAC 360 controller with system LCD display. It can memory 100 shear programs, each program can be made up of 25 steps. Also, the system can control the backgauge, shear angle, blade gap, and has automatic return function, which avoids the friction between the sheet and the blade.

Usually front feeding guillotine shear is customized because customers have different requirement for their front feeding table size. Please feel free to contact with us if you need help to choose machine model.

The CNC V grooving machine is used in industries that require high-precision plate processing, such as elevators, packaging materials, stainless steel processing, household appliances, and prop display.

If the v grooving machine is installed with some special accessories, it can also grind, polish and draw metal sheets and profiles. If some special workpieces cannot be bent and formed in the bending machine, or the product is completed with a specially designed complex mold, but the depth of the V-shaped groove of the metal sheet is controlled by a CNC stainless steel v groove machine, this special bending material is also It can be bent and formed with a general-purpose mold on a common press brake machine.

Plate Thickness: up to 6mm

Plate Length: up to 6000mm

Groove V machine can be divided into CNC Horizontal V Grooving Machine and CNC Vertical V Grooving Machine. Vertical V groove machine can groove thicker plate than the horizontal one.

Press Brake

Panel Bender

Plate Rolling Machine

Press brake is the most commonly used bending machine in the sheet metal processing factories. It is an important equipment for bending and forming workpieces in the sheet metal industry. Its function is to press the steel plate into parts of various angles and shapes according to the process requirements.

The frame is mainly composed of left and right columns, worktables and beams. The left and right oil cylinders are fixed on the columns. The sliders are connected with the pistons of the cylinders and move up and down along the guide rails fixed on the columns. The lower die is fixed on the workbench, and the upper punch is installed on the lower end of the slider, the hydraulic system provides power, and the electrical system gives instructions. Under the action of the oil cylinder, the slider drives the upper die to close with the lower die to realize the bending of the sheet. The left and right columns, worktable and slider (hereinafter referred to as the three major parts) are the key parts of the bending machine, and the sum of the weight of the three major parts accounts for 70% to 80% of the total weight of a bending machine. Its strength and rigidity directly determine the running accuracy and service life of the machine tool, as well as the precision of the workpiece.

Press brake machine is divided into manual press brake machine, hydraulic press brake machine and CNC press brake machine. Manual press brake is divided into mechanical manual bending machine and electric manual bending machine, and hydraulic press brake machine can be divided into synchronous mode: torsion shaft synchronous NC press brake and electro-hydraulic synchronous CNC press brake. According to the movement mode, the hydraulic press brake machine can be divided into: up-moving type, down-moving type.

Hydraulic CNC press brake machine is composed of a full-closed-loop CNC system of the press brake, two grating rulers, a photoelectric encoder for real-time detection and feedback, and a stepping motor to drive the screw to form a full-closed-loop control. Two grating scales; one for the back gauge and one for real-time detection and feedback of the position of the slider; the photoelectric encoder detects and feeds back the position of the dead block of the cylinder to the numerical control system.

Bending capability: 40-1200 Tons

Bending length: 1320-10000MM

1. Directly perform angle programming, with angle compensation function, and the operation is easier.

2. Magnetic scale real-time detection feedback correction, full closed-loop control, back gauge and slider dead gauge positioning accuracy is ±0.01mm. The computer system controls the back gauge of the bending machine, and the bending accuracy is higher.

3. The upper punch adopts a quick clamping device, and the lower die adopts a wedge deformation compensation mechanism.

4. It has multi-step programming function, which can realize multi-automatic operation, complete one-time processing of multi-step parts, and improve production efficiency.

5. Uneven load bending is possible, and the service life of the machine is longer.

6. It can be connected with robots to achieve fully automatic production.

The servo hybrid press brake machine uses split double oil tanks, has an independent shock-proof buffer layer, and has a better mute effect. The position signals from the left and right sets of magnetic scales are used to control the left and right servo main motors through the computer. The left and right oil pumps are controlled respectively through forward rotation and rotational speed to generate the same flow and pressure, so that the left and right oil cylinders move synchronously and press up synchronously.

When the oil pump rotates forward, the slider goes down; when the oil pump rotates in reverse, the slider goes up. The left and right oil cylinders, oil pumps, servo motors, magnetic scales and computers form two closed-loop systems.

The servo motor rotates slightly during standby, quiet and energy-saving. When fast down, according to different speed requirements, the speed of the servo motor is different (high speed, low torque). During bending, the torque of the servo motor is different (high torque, low speed) according to the bending pressure. During the return trip, the speed of the servo motor is different (medium torque) according to different speed requirements.

1. Wuxi Shenchong oil-electric hybrid CNC system has the characteristics of high efficiency, energy saving, high precision, low noise, and environmental protection. The oil-electric hybrid CNC bending machine has better synchronization, real energy saving and high efficiency, simple structure and faster speed.

2. After actual testing, the repeated positioning accuracy of the slider is ±0.01mm, and the highest accuracy can reach 0.005mm.

3. Low noise is also one of its biggest features. During the use of the same model, the noise is basically controlled below 65 decibels, which greatly improves the superiority of the working environment.

4. Since there is almost no energy loss in the servo pump control system, the whole process will not cause a significant rise in oil temperature. When the ambient temperature is 38°C, the continuous working oil temperature shall not exceed 50°C. Thereby reducing the risk of oil leakage, higher stability, and improving the service life of all seals and cylinders in the hydraulic system.

5. According to our practical testing, Shenchong servo press brake saves 85% energy in one hour, and 70-80% energy in three hours.

The advantages of the flexible CNC bending center are not limited by the column spacing and throat depth of the C-shaped structure frame design, and can make full use of the bending machine for processing, which is more dexterous and convenient. Moreover, its servo-type design allows quick start and stop of the machine, and the processing speed is fast, which can shorten the processing time.

The advantage of the flexible CNC panel bender is that it can automatically realize the bending of the four sides of the plate in turn, realizing automation. The universal universal bending die can realize double-sided bending of the plate. The CNC positioning device is used for automatic positioning, and the multilateral bending can be completed in one positioning.

The intelligent flexible bending center has a wealth of software and hardware interfaces, which can be selected according to the conventional mechanical arms on the market, and can be selected according to the actual needs of the demand side;

The control system realizes the real nine-axis (11-axis) concurrent linkage, smooth bending action, and high coordination of mechanical operation;

The intelligent flexible bending center eccentric load inspection system, eccentric load follow-up system, and thick plate detection system can effectively protect the machine, protect the workpiece, and reduce the waste of the workpiece;

For workpieces with non-standard sizes, different positioning references can be selected according to the shape of the workpiece, so as to control the shearing error of the plate on the first bending edge and ensure the dimensional accuracy after forming. Rapid prototyping with high consistency and low power consumption.

Application: CNC panel bender is best for sheet metal narrow side bending.

Roll bending machine is a shaping machine tool for continuous point bending of plates, and has the function of rolling plates of different shapes such as O-shaped, U-shaped, and multi-section R. Equipped with auxiliary devices, it can also roll conical, oval and other workpieces. Widely used in boiler, shipbuilding, petroleum, chemical industry, hydraulic engineering, metal structure and other machinery manufacturing industries.

Plate rolling machine can also be divided into 3 roller bending machine and 4 roller bending machine. 4 rolls rolling machine with CNC controller can pre-bend the sheet metal and bend the cone roll at high precision level.

There are hundreds of different sheet metal machines that can help to process plates. This article will continue to introduce and updates different equipment for customers to quickly learn what they should purchase for their factory.