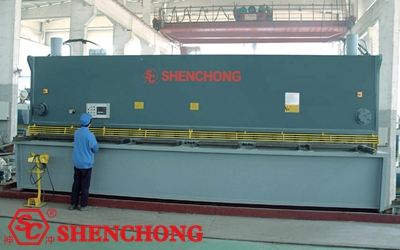

Guillotine Steel Cutting Machine is a kind of forging equipment, which is mainly used in the field of cutting and processing of metal materials. It is widely used in aviation companies, light industry, metallurgical industry, chemical plants and other fields.

Like CNC press brakes, roll bending machines and other mechanical equipment, plate shearing machine has safety risks in practical operation and application.

As an industrial equipment, when using the guillotine plate shear machine for metal cutting, users need to pay attention to the operation specifications and safety issues. Improper operation is not only easy to cause huge shearing error and abnormal defective rate, but also can cause safety problems for operators.

The following are the precautions for the operation specification of plate shears summarized by Shenchong professional plate shearing manufacturer for customers.

- On the basis that the shear is firmly fixed, the lock nut on the anchor bolt shall not be loose. The tool holder moves steadily up and down.

- For hydraulic plate shears, the upper tool rest (or sliding block) shall be free of creeping, stagnation, vibration and obvious impact within the specified travel range.

- The pressing foot of the clincher shall be free from serious wear. The shear plate is pressed evenly.

- The working process and action sequence are normal.

- The upper blade tool rest stops at the specified position.

- The worktable shall be flat and clean without welding scar and oil stain.

- The supporting ball is flexible and the feeding is convenient.

- The blade rest of the steel cutting machine is closely fitted with the fixed joint surface of the bearing surface.

- The tool holder is installed correctly. Tighten the fixed screws.

- The blade working clearance adjusting device is locked reliably. The adjusting bolts shall be slippery and free from disorderly fastening and protruding from the worktable.

- The tool holder balancing device has a self-locking safety structure and protective measures.

- The tool holder balancing device can ensure that the tool holder can balance itself at any position of the stroke.

- The blocking device is accurate in operation, flexible in adjustment, convenient in feeding and reliable in use. Have a complete blocking and yielding mechanism.

- The rolling, lifting and other actions of the supporting device are flexible and stable.

- The cooperation and action coordination of the controller and its control mechanism.

- The hydraulic system and lubrication system shall be free of blockage and leakage.

- There is no leakage in the gas pipeline system.

- The lubricating oil of the guide rail is provided with a device for oil return or containment.

- Hydraulic and pneumatic systems are equipped with protective measures and display devices for sudden disappearance of hydraulic pressure and air pressure or interruption of liquid and air supply.

- During operation, the oil temperature in the oil tank shall be lower than 50 ℃.

- After 24 hours of continuous full load operation, the temperature shall be lower than 60 ℃.

- The pressure gauge of the guillotine shear machine hydraulic system shall be clear, sensitive, accurate and reliable.

- The gear rotates stably without irregular impact sound. The noise of plate shears in idle operation is lower than 90dB.

- Transmission gears, couplings and other rotating parts exposed outside the bed that may endanger personal safety are equipped with protective devices.

- The dangerous parts where the steel cutting blade may fly out must be equipped with protective baffles.

- The dangerous parts of the knife rest and pressing device of the shear plate must be provided with protective measures.

- Shielding protective devices such as baffles, covers and nets of the steel cutting shear can reach the width of the protective fence equivalent to the width of the scissors or the width of the workbench. It can not only prevent entering the dangerous area of shearing and pressing, but also facilitate observation and operation. It is not easy to be removed by the operator.

- Workers shall not contact with moving parts of the machine tool during operation.

- The electrical equipment meets the design requirements. The nameplate is clear. The installation is firm.

- The electrical connection is good. Anti loose measures shall be taken for wire joints.

- Anti vibration measures shall be taken for electrical appliances with vibration effects.

- The pneumatic control system shall be equipped with emergency stop button.

- Guillotine hydraulic shear motor wiring shall be covered with metal protective tube.

- The door of the electrical box is complete and tightly closed, and the pressing screw (or door lock) is complete and fastened. Keep the interior clean and dry.

- All electrical parts and wiring terminals shall not be loose. The protective grounding wire of the machine tool is good.

- The guillotine steel cutting machine shall be provided with nameplates and labels or signs indicating lubrication, operation and safety.