When customers purchase press brake machine, they are often confused in whether to purchase a CNC press brake machine or a NC press brake machine. Both of the two types of press brake machines bend workpieces to different angles and shapes through different upper and lower toolings.

Actually they have many differences, We analyze from the following aspects:

Usually we name Torsion Bar Press brake as NC press brake, name Electro-hydraulic press brake as CNC press brake.

The structural principles of CNC press brake and NC press brake are different, so keeping the synchronization of the left and right sides of press brake machine slider are different.

The entire machine is in fully steel welded structure with stress eliminated by vibration aging technology. The machine mainly consists of the left and right wall boards, working table, oil box, slot steel, synchronizing shaft, sliding block, etc.

It enjoys high accuracy and high strength and can be transported easily. Machine tool have the function of point move, single and continuous, fast and slow area distinguishing slider. Area can be adjusted independently.

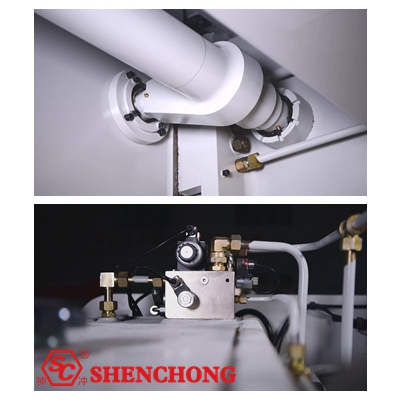

Snychro control system:

It also adopts steel torsion bar synchro system with very simple structure but very high accuracy. At both ends of the sliding block, there are 2 synchro folks which make the sliding block movement always parallel to working table. This structure highlights a balanced movement effect during operation. Upper die compensation is used to improve the brake precision.

- The whole steel plate of CNC hydraulic press brake is welded and the stress is eliminated by the vibration after tempering sandblasted and sprayed with anti-rust paint.

- The machine frame is processed by imported CNC three-dimensional processing center, which ensures the parallelism and verticality of each installation.

- The CNC hydraulic press brake machine has good rigidity and stability.

- Adopt Hydraulic transmission to ensure stable and reliable operation.

- Use electro hydraulic servo system, full closed loop feedback control synchronization.

- Bending machine throat deformation prevention system to ensure the accuracy of bending.

- Comfortable operation and state-of-the-art technology significantly improve the bending efficiency.

Snychro control system:

The electro-hydraulic press brake machine is equipped with magnetic scale on the slider and the machine wall plate. The CNC controller system can analyze the synchronization on both sides of the slider through the information which fed back by the magnetic scale in real time. If there is an error, the CNC controller adjust the difference through the proportional electro-hydraulic valves ,to synchronize the strokes on both sides of the slider. The CNC controller, the proportional electro-hydraulic system, and magnetic scale constitute the feedback closed-loop control system of CNC hydraulic press brake machine.

The parallelism of the slider will affect the bending angles. NC press brake machine is with mechanical forced synchronization method, and the parallelism of the slider can not be checked and adjusted automatically. In addition, NC press brake is not allowed of eccentric load, the torsion shaft of NC press brake machine force the synchronous mechanism to move, which will make the oil cylinders on both sides up and down moving. If the eccentric load bending for a long time, the torsion shaft will be deformed.

The CNC hydraulic press brake machine keep the slider synchronization through the proportional electro-hydraulic valves, and the real-time error feedback by magnetic (raster) scale. If there is an error, the magnetic (raster) scale will feedback in real-time, then the CNC controller will adjust through the proportional valves for keeping the synchronization of the slider.

The main factors which can affect press brake machine running speed:

(1) The slider moving speed,

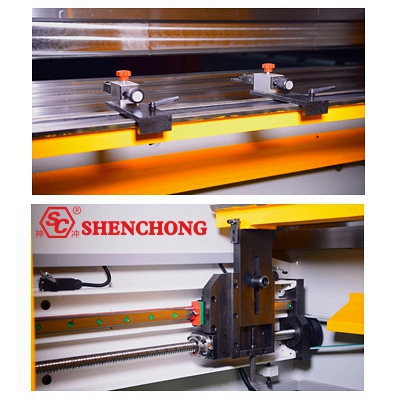

(2) The backgauge moving speed,

(3) The bending steps

- For NC press brake machine, usually we choose the oil cylinder 6:1 or 8:1, speed is slow. For CNC press brake machine, usually we choose the oli cylinder 13:1 or 15:1, speed is fast. So the idle speed and returning speed of CNC press brake are much faster than NC press brake.

- NC press brake, although has fast descent and working speed, the speed of fast descent and return speed can only upto 100mm/s, and the speed conversion is not smooth. The backgauge running speed is only upto 150mm/s.

- CNC press brake, also has the fast descent and working speed, but the fast descent and return speed can reach 200mm/s, the speed conversion is smooth. The backgauge running speed can reach 500mm/s. All these can greatly improve the production efficiency.

- When the workpiece needs multi-step bending, each step of NC press brake need be set separately, the process is very time-consuming. But for CNC press brake, we can set and save multi-step as a program, can operate continuously, which greatly improve work efficiency.

High Speed Mini Press Brake For Sale

NC press brake not equipped with CNC contron system, not with V-axis compensation, When bending new workpieces, the experienced operators only can make trial bendings firstly, if not meet the standard sucessfully, we have to continue to try. This not only waste a lot plates, but also the experienced operators need higher salary.

CNC press brake with CNC control system, also with V-axis compensation, easy operation, and low requirements for workers' experience. The CNC controller with the function of simulating bending, no need to make trial bending, the bending can be performed directly.

NC press brake machine, because of the machine own structure, the machine not allowed eccentric load. If bend by eccentric load for a long time, the torsion shaft will be deformed.

CNC press brake machine, because the left and right cylinders (Y1, Y2, two axes) move independently, so the eccentric load bending is allowed.

- Traditional structure by using the torsion bar synchronize Y axis

- Standard X, Y, 2 axis

- ESTUN E21 NC Control Unit

- Motorized Back Gauge

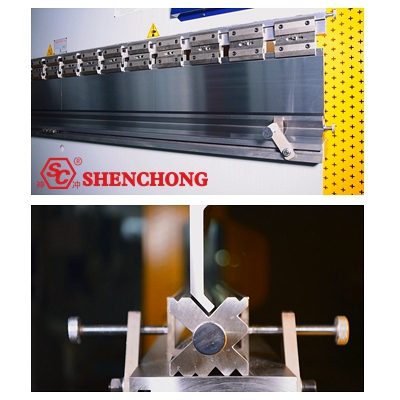

- Upper punch compensation.

- FIRST Valves (U.S.A)

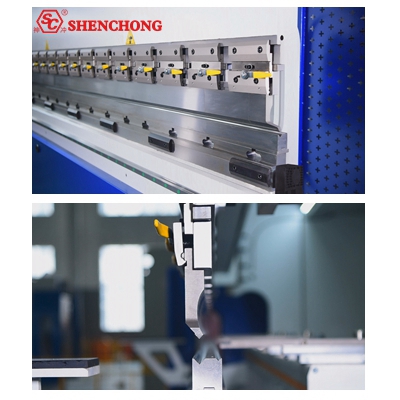

- Full length multi V die, Upper punch with segmentation 835mm

- NOK Seal Ring

- Side and Rear safety protection

- Mechanical crowning system by Manual

- Electrical cabinet with Telemecanique Schneider, Esautomotion, ABB components

- ESA CNC Control Unit S630 (Optional DELEM )

- 4+1 or more axis CNC

- Y1, Y2 precision ram positioning

- Standard X and R-axis

- CNC dynamic crowning

- Large open height/ stroke/ throat depth

- NOK seal ring

- Schneider and ABB electric components

- Siemens motor

- Side and Rear safety protection

- Sheet metal frontal supports

- SUNNY Pump

- Ball screw and linear guide

- Rear backgauge fingers with 3 blocks, and double linear guide

Steel structure industry, rough machining factories, truck manufacturing industry etc…

Due to the structure limitation, Wuxi Shenchong does not recommend customer to choose torsion bar synchronous press brake when they buy model above 400tons.

All factories need to use press brake can choose CNC Press Brake machine.

For different kinds of sheet metal bending process.

- Decoration industry: chassis, cabinets, elevator, doors and windows, curtain wall, etc.

- Construction industry: steel structure, tower, bridge, etc.

- Mechanical equipment manufacturing: environmental protection equipment, animal husbandry equipment, solar energy equipment, heat insulator, transformer, etc.

- Electric appliance and power industry: electrical pole, lamp pole, electrical equipment, electronic device, etc.

- Automobile and ship industry

- Aerospace Industry

If you still have doubts on choosing NC press brake and CNC press brake, please feel free to contact WUXI SHENCHONG at any time.