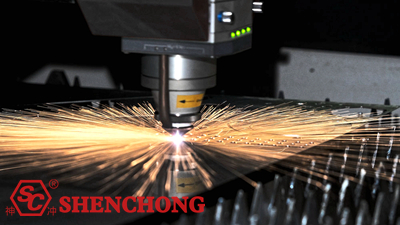

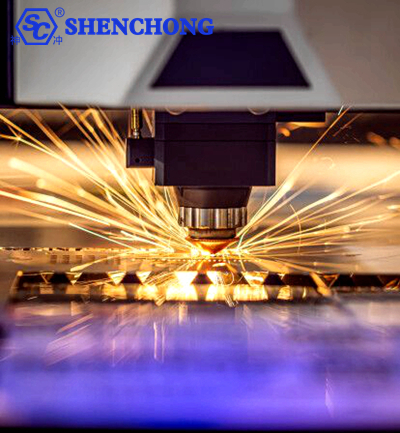

2025 fiber laser cutting machine market is growing steadily and is expected to continue this trend in the future. Fiber laser cutting machine is a device that uses high-power fiber lasers for cutting and processing, and has the characteristics of high precision, high efficiency and low energy consumption.

With the advancement of intelligent and automated manufacturing, fiber laser cutting machines are increasingly used in metal processing, automobile manufacturing, aerospace, electronics and electrical, home appliances and other industries, and market demand continues to grow.

The global fiber laser cutting machine market has maintained steady growth in recent years, mainly benefiting from the continued expansion of industrial automation, intelligent manufacturing and metal processing demand. China, Europe and North America are the main markets. China has become one of the fastest growing regions due to its developed manufacturing industry and government support policies.

According to the forecast of market research institutions, the global fiber laser cutting machine market is in a rapid growth stage, and the average annual compound growth rate (CAGR) is expected to be about 7%-10% from 2024 to 2030.

- Asia Pacific (China, Japan, South Korea, India, etc.)

China is the world's largest market, mainly benefiting from manufacturing upgrades, government policy support and the rise of local brands.

The Japanese and Korean markets are dominated by high-end precision manufacturing.

- Europe (Germany, Italy, Switzerland, etc.)

Famous for high-end laser cutting machine technology, representative companies include TRUMPF, Bystronic, etc.

- North America (United States, Canada)

The main markets are in aerospace, automotive manufacturing, electronics manufacturing and other fields, and IPG Photonics is one of the main suppliers.

- Other emerging markets (South America, Middle East, Africa)

The industrialization process is accelerating, and the demand for fiber laser cutting machines is rising.

With technological advances, fiber laser cutting machines with power of 6kW and above are gradually replacing traditional CO₂ lasers and low-power equipment to improve cutting efficiency.

CNC technology, Internet of Things (IoT) integration, remote monitoring and other technologies promote equipment intelligence, improve production efficiency and reduce labor costs.

The demand for processing materials such as stainless steel, aluminum alloy, and high-strength steel has increased, driving the technological upgrade of laser cutting equipment.

Fiber laser cutting machines are more environmentally friendly and energy-saving than traditional cutting methods (such as plasma cutting and flame cutting), which is in line with the global green manufacturing trend.

Mainly for the high-end market, with advanced technology and higher prices.

- TRUMPF (Germany)

- Bystronic (Switzerland)

- AMADA (Japan)

- IPG Photonics (USA)

Technology is gradually catching up with international brands, with high cost performance, and occupying a large share in the mid-to-high-end market.

- Hans Laser

- HGTECH

- SC SHENCHONG

- Bodor

- Jinan G.WEIKE Laser

More and more small and medium-sized enterprises are entering the market, focusing on specific fields or low-cost equipment, and the competition is fierce.

- Industry 4.0 and intelligent manufacturing promote enterprises to adopt automated and intelligent laser cutting equipment.

- The integration of robot + laser cutting technology improves production efficiency.

- Traditional 3kW-6kW fiber lasers are gradually developing towards ultra-high power of 12kW, 20kW or even 30kW.

- High-power laser equipment can improve the cutting capacity of thick plates and improve production efficiency.

- Automated cutting equipment reduces dependence on manual labor and improves production efficiency.

- Ultra-high power lasers, fine cutting, AI control and other technologies enhance the competitiveness of equipment.

- Photovoltaic industry: The demand for precision laser cutting of photovoltaic modules, silicon wafers, brackets, etc. has increased significantly.

- New energy vehicles: Power batteries, body structural parts, thermal management system components, etc. require high-precision laser processing.

- Fiber laser cutting is more energy-saving and environmentally friendly than traditional cutting methods (plasma, flame cutting), which is in line with the global carbon neutrality trend.

In the past, the mainstream power was 3kW-6kW, and now it has developed to 12kW, 20kW, and even 30kW+.

In the future, high-power laser cutting machines will be widely used in thick plate cutting, such as stainless steel, aluminum alloy, carbon steel, etc.

Impact: Improved cutting efficiency, reduced processing costs, and increased demand for high-end manufacturing.

High-power Fiber Laser Cutting Machine Buyer Guide

Optimize cutting paths through AI, reduce waste, and improve efficiency.

Visual recognition and automatic compensation technology improve cutting accuracy and quality.

Combined with industrial robots, unmanned processing is realized and labor costs are reduced.

Smart sensors + Internet of Things realize remote monitoring and fault prediction.

Laser cutting is combined with stamping, bending, welding and other processes to improve integrated manufacturing capabilities.

Reduce dust and smoke emissions, optimize energy consumption management, and meet carbon neutrality goals.

Competition in the low-end market is fierce, and price wars between domestic brands are serious. Intensified market competition has led to a decline in profit margins.

High-end fiber lasers (such as IPG, nLIGHT) and high-precision optical devices still rely on imports, and the localization rate of some key components is not high. The high-end market is still occupied by European, American and Japanese companies, and domestic brands have technical shortcomings in high-power lasers and core optical components.

Affected by fluctuations in the macro economy and manufacturing investment, market demand may change cyclically. Affected by the prosperity of the manufacturing industry, market demand is volatile, especially when the economy is unstable.

The fiber laser cutting machine market will continue to grow in the future, especially in the direction of high-end manufacturing, intelligent manufacturing, and green manufacturing. Domestic enterprises will accelerate technological breakthroughs, increase the localization rate, and expand to the international market, which will become an important development trend of the industry in the future.

- Development in the direction of high-end and intelligentization: high power, high precision, and intelligent control will become the mainstream trend.

- The rise of domestic brands: domestic fiber laser technology continues to break through, with obvious cost advantages, and gradually seize the mid-to-high-end market.

- The new energy industry drives growth: photovoltaic, battery, hydrogen energy and other industries have a strong demand for high-precision cutting, which drives market expansion.

- Global market expansion: Chinese brands accelerate exports, and demand in emerging markets such as Southeast Asia, South America, and the Middle East is growing.

Overall, the market prospects for fiber laser cutting machines are broad, and with technological breakthroughs and increased industry demand, it will continue to maintain steady growth in the future.