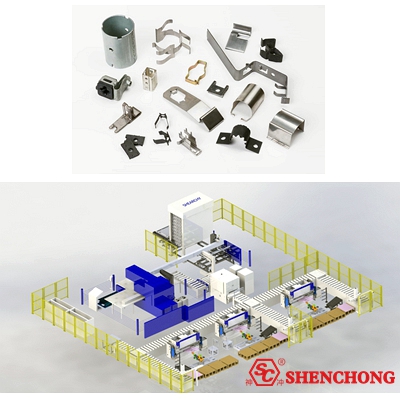

Sheet metal stamping forming processes transform by stamping hot-rolled or cold-rolled steel sheets into the shapes needed to manufacture your components. This technique allows a large number of parts to be produced simultaneously, but it can also result in about 15% of the raw material becoming scrap.

The equipment used by this method requires less space than other methods, so if you have limited space, this type of fabrication may be best for your business. When working with sheet metal stamping and forming, there are three main types of dies used - cutting, punching and bending.

Trimming involves cutting a part out of a sheet of metal. This is done by striking the sheet metal with a die, which shears the sheet metal into the desired shape. The edges of punched parts will have burrs, so they need to be filed or machined before use.

Punching is the process of punching a hole in a sheet of metal by placing it between two dies and forcing them together.

Bending is the deformation of metal by using the pressure of a die, and this type of stamping is often used to make parts with curved lines.

Some frequently asked questions:

In the process of punching or cutting corners, there are not enough residual materials, and burrs are generated on the lower part of the cut-off surface of the steel plate. Based on the cut-off surface, when the height of the burrs is more than 0.2mm, the iron powder generated will damage the mold and produce unevenness.

The surface of the material is abnormally convex or concave, which is caused by the mixing of foreign matter (iron filings, dust) in the uncoiler.

It is caused by foreign matter attached to the cleaning roller or the feeding roller (occurs at a fixed pitch). Generally, the foreign matter on the roller print on the sheet can be removed.

Caused by roller slippage, occurs when suddenly stopping or accelerating.

The wrinkling caused by the small gap between the guide rollers of the uncoiling line or the guide rollers on the mold is caused by the imbalance of the coil feeding.

The main reason for scratches on the parts is sharp scratches on the mold or metal dust falling into the mold. The preventive measures are to grind the scratches on the mold and remove the metal dust.

The main reason for cracking at the bottom of the part is that the plasticity of the material is poor or the blankholder of the mold is pressed too tightly. The preventive measures are to replace the material with better plasticity or loosen the blankholder.

The main reason for the wrinkles on the side wall of the part is that the thickness of the material is not enough or there is a deviation when the upper and lower molds are installed, resulting in a large gap on one side and a small gap on the other side. The preventive measures are timely replacement of materials and readjustment of the mold.

Sheet metal stamping is a low-cost manufacturing technique. It usually costs less than other methods, making it ideal for small businesses on a budget. Since this method does not require molds or tooling to create the part or part, many believe it is also less expensive. However, the toolless aspect of sheet metal stamping can sometimes make it more expensive, as you need to pay someone to do the layout and design work instead of using standardized tooling.

Sheet metal stamping forming can create thousands of identical parts at a time, so this type of fabrication allows you to efficiently manufacture high volumes while maintaining quality standards. This benefit mostly applies to parts with simple shapes that don't require a lot of customization.

Shears, punches, and bending dies make up most of the tools for sheet metal stamping, so this type of fabrication is relatively easy to learn. If you have employees who are already familiar with basic machine operations, they'll probably know how to punch sheet metal without too much trouble.

Sheet metal stamping forming is a very versatile manufacturing technique capable of creating parts of various shapes and sizes. This makes it a good choice for businesses that require high-volume production. Additionally, this type of stamping can create both simple and complex parts.

Maybe You also want to know about CNC Press Brake For Sale

Sheet metal stamping has an inherently high scrap rate. To work properly, stamping dies require a flat, smooth sheet metal surface. If the sheet is uneven, the result will be poor and the metal will have to be scrapped. Because this manufacturing process requires large areas of sheet metal, you run the risk of wasting many small pieces that don't meet quality standards. Obviously, mass production will increase your scrap volume.

It is simple and clear, almost no custom-made machine parts are required, and the best effect is to use sheet metal stamping technology. Simple shapes and curves make fabrication easy and cheap. However, you may need to pay more when using this technique on custom projects or highly detailed parts due to design fees and the cost of additional labor required to complete the project.

Sheet metal stamping is the best choice for making simple parts, but if you need a more complex or detailed part, it may not be the best manufacturing choice. The stampings used in sheet metal stamping cannot easily produce tight curves or intricate details, so if your part design is complex, you may have to look elsewhere.

Sheet metal stamping and forming is labor intensive and often slower than other manufacturing techniques. This can be an important disadvantage if you need a lot of products that are manufactured quickly.

If you need many parts quickly and at low cost, then sheet metal stamping is the better choice.