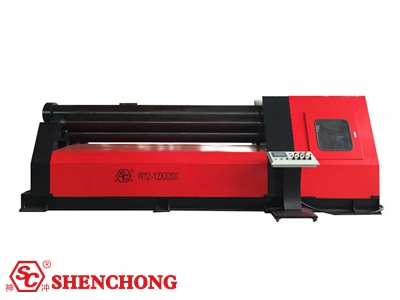

The fully automatic hydraulic four-roller CNC rolling machine has advanced and reliable technical structure and sufficient rigidity. The key parts such as work rolls are made of reasonable materials, precision manufacturing, excellent performance, long precision retention period, and are suitable for long-term continuous processing. The operation control is stable and reliable, and the operation is simple. It is a unique advanced equipment used for rolling metal sheets with high precision and high efficiency.

The W12 four-roller plate rolling machine consists of working rolls (one upper roller, one lower roller, two side rollers), a frame (a high frame, a short frame, one for each tipping support), a base, a hydraulic transmission device, The hydraulic pump station and main engine are composed of seven oil cylinders (four side roller moving cylinders, two lower roller lifting cylinders, one inverted cylinder), unloading device, solenoid valve group and a set of CNC electric control system.

Working roller: The working roller is the main key working part of the machine. The material of the working roller is 42CrMo, forging, quenched and tempered after rough machining, and the hardness is HB270~300.

The working process of the working roller is: forging→heat treatment after forging→rough turning→quenching and tempering→finishing turning→surface quenching treatment→finishing grinding.

Four-roll plate rolling machine, the position of the upper roll is fixed, the lower roll and the side roll can be moved up and down, the rotation of the work roll is hydraulically driven, the lower roll and the side roll are moved up and down by parallel oil cylinders at both ends, and the discharge end of the upper roll is turned over. The overturn and reset of the bracket are carried out by the oil cylinder. Each roller bearing body and oil cylinder are installed in the frame at the left and right ends.

1) The plate is fed horizontally - unlike the inclined feeding of the three-roll plate rolling machine

2) Use side rollers to quickly align the plate (avoiding the risk of misalignment)

3) Only take up space on the loading side

4) The edge of the straight line is greatly reduced (due to the excellent pre-bending ability, the clamping point completely falls on the edge of the sheet)

5) The easiest equipment to roll, each side roller only needs one position to roll and form

6) The whole process is formed at one time (provided that the equipment capacity option is appropriate), including the pre-bending of the plate head

7) The post-bending of the sheet is suitable for high-efficiency automatic roll manufacturing.

And following is the correct operation steps of the four-roll CNC plate bending machine:

(1) The plate rolling machine must be managed by a special person.

(2) Wuxi Shenchong plate rolling machine manufacturer reminds the operator that they must be familiar with the structure, performance and use of the plate rolling machine, and can operate it only after the approval of the responsible management personnel.

(3) Before starting the machine, carefully check whether the safety device is in good condition.

(4) During operation, it is strictly forbidden to put hands and feet on the rollers, transmission parts and workpieces.

(5) After the work is interrupted, the clutch should be turned to neutral.

(6) The collaborative operation of multiple people must be directed by a special person.

(7) Overwork is strictly prohibited.

(8) The tilting and resetting of the lifting and turning bearing of the upper roller and the balance of the upper roller must be carried out after the main drive is stopped.

(9) It is forbidden to pile up workpieces and sundries in the workplace, and keep the machine tool and the site clean at all times.

(10) After the work is completed, the power should be cut off and the power box should be locked.

The W12 four roller bending machine is an important equipment in the production of the enterprise. It must be operated in the correct way during working process. Otherwise, not only the equipment will be damaged and the production will be affected, but also unexpected consequences will occur. So, please must pay more attention to operation manual and machine itself.