Sheet metal robots can be used in every process of sheet metal forming, from loading to uncoiling and leveling to shearing, to laser cutting, stamping, bending, welding, grinding, spraying and stacking. But each link is different.

From the perspective of the whole process flow, which steps are more suitable for using robots? How to use robots better?

Let's take some industry examples to introduce some common application scenarios of sheet metal robots.

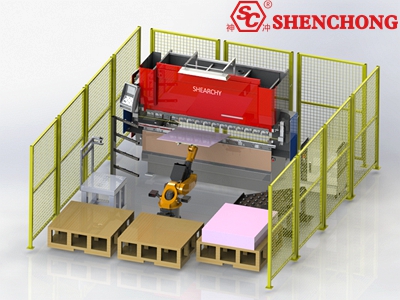

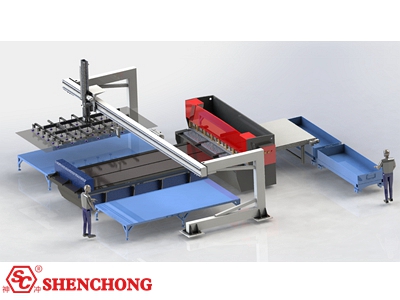

Robotic press brake used to bend large and heavy sheet metal. Automatic loading or unloading robot can be applied to plate shearing machines. In the field of laser cutting, robots can be used for loading, unloading and sorting.

In addition, welding is a field in which robots are widely used. Grinding can also be carried out by professional industrial robots. In the field of painting industry, robots are seldom used now. The last is palletizing. In this aspect, we will also use robots to form a intelligent storage system.

Not all sheet metal industries are suitable for robots. At present, robots are suitable for large sheet metal processing fields where a large number of labors used. This field is characterized by the need for many workers and much manpower.

1) Robotic press brake bending technology has matured. Robot bending not only meets the basic processing requirements, but also excavates the interconnection between automatic molds and other equipment.

2) The robot welding requires high consistency of incoming materials. For example, metal furniture, metal boxes or common office filing cabinets. How to use robots to achieve perfect fit during splicing. This is a challenge for all practitioners.

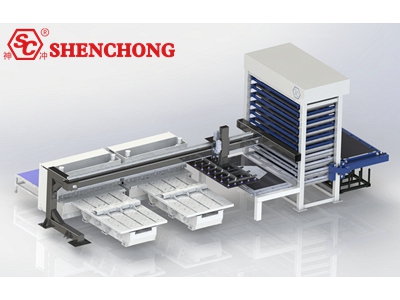

3) Stamping and laser loading and unloading are relatively mature. Robotic sorting needs further development. It is relatively easy to load plates. Unloading and sorting sheet metal is difficult. Punch blanking is very difficult to handle in some cases.

4) Robot grinding and polishing are under research. Its difficulties still remain in the problem of "multiple varieties, small batch".

5) Robots are also used in many fields of sheet metal spraying. However, at present, most of the them are reciprocating automatic spraying machines.

6) The initial purpose of using sheet metal robot is to improve productivity and reduce labor related costs. Today, the focus of automation has shifted to improving the quality and flexibility of manufacturing processes.

It is well known that only a single variety, large batch, dedicated equipment, stable process and high efficiency can achieve economies of scale. On the contrary, multi variety and small batch production has poor benefits. In the case of similar processing forms, tooling and fixtures shall be adjusted frequently. This greatly increases the difficulty of process stability and affects the production efficiency.

The overall development problem of robot application in sheet metal industry is still "multi variety, small batch". However, "Robot+AI" may become a direction for subsequent force generation.

SHENCHONG automatic sheet metal production line is customized according to the actual needs of customers to ensure the highest flexibility and flexibility, so that customers can get the most suitable solution.