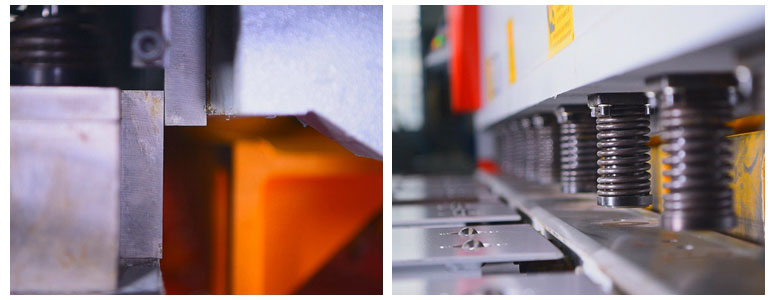

Hydraulic shearing machines have a history of many years in the industrial history. And now they have become common equipment in the machinery industry. However, sometimes the procurement departments often do not know how to choose a good and suitable blade.

It is believed that the better the material, the better the blade of the shearing machine is. In fact, the shearing blade material depends on the type of plate which will be cut by the shearing machine.

The material of the blade usually includes: T8, T10, 9CrSi, 6CrW2Si, Cr12MoV, SKD-11, W6Mo5Cr4v2, H11, H13, etc. There are different kinds of blade material, for example: Carbon knotted tool steel, low alloy tool steel, alloy tool steel, etc.

The blade material should be strictly selected, carefully processed, high-standard heat treatment, meticulous iron grinding, and strict inspection to ensure the quality of each blade.

Shearing blade carbon-knotted steel is generally made of steel 65, 75, T8, T10 and other materials.

The heat treatment hardness of the blade produced by this material is within the range of HRC57-59 degrees, which is suitable for ordinary low-carbon cold-rolled sheets.

A3 steel and Recycling scraps, this feature is low cost and reasonable price.

The common CNC hydraulic shearing machine blade material of low alloy tool steel are: 6Crw2sI, Cr5molv, 9CrSi, Cr12MoV, etc.

The heat treatment hardness of the blade is in the range of HRC58-62 degrees. It is specially used for cutting stainless steel hot rolled plate, medium and thick plate.

Cutting blade material of alloy tool steel are: 4Cr5MoSiV1 (H13K), 7Cr7Mo2V2Si9 (LD), W6Mo5Cr4V2 (6542) H13, etc.

The blade of this material is used for cutting hot-rolled billet, hot-rolled medium and thick steel plate, etc. The feature is high temperature resistance, not easy to anneal. For hot rolling, hot shearing processes in steel mills.

plate cutting → forging → tempering → metal processing → inspection → quenching → annealing → quenching and tempering → rough grinding → fine grinding → inspection → packaging and delivery

The blade is strictly selected, carefully processed, high-standard heat treatment, meticulous iron grinding, and strict inspection to ensure the quality of each blade.

- Start the shearing machine for several cycles of idling, make surethat under normal conditions, try to cut sheets of different thicknesses, from thin to thick. Make sure the user is familiar with shearing machine performance.

- During trial shearing,different blade gaps must be adjusted for different plate thicknesses. If not adjust the corresponding blade clearance, the blade will be damaged, and the blade durability will be affected.

- During the shearing process, weneed to observes the pressure value of the oil circuit. The pressure should be less than 20MPa when cutting plate thickness 12mm.

- During operation,the machine sound balance. If the shearing machine there is a noisy, we should stop the machine for inspection.

- When we operate the shearing machine, the maximum temperature of the oiltank should be less than 60 degrees, if the temperature exceed it, we should turn off the machine and rest until the temperature drops.

We should follow the below steps when using shear blades:

- Strictly follow the operating procedures

- Every time before starting the machine, according to the requirements of the smoothing chart, add lubricating oil on time, at a fixed point, and definite quantity. The oil should be clean and free of precipitation.

- Check every time before staring the machine: shear blade clearance if correct.

- We must keep clean of the machine, and the machine must be lubricated and anti-rust grease regularly.

- Check whether the shearing blade V-belt, handle, knob and button are damaged on time. If the wear is serious, weshould replace it in time and report for spare parts.

- Avoid cutting thewelded sheets.

- The shearing machine blade can not cut the plate with impurities or with hard objects.

- Avoid cutting thick plates beyond the limit. Regularly adjust the upper and lower blade clearance.

- Regularly check and repair switches, fuses and handles, make suretheir reliable operation.

- It is strictly forbidden for non-designated personnel to operate the equipment, and usually people must stop the machine before leavingthe machine.

The plate shearing blade is used to cut various metal materials. It is an important part of the shearing machine. The blade material and processing determine the using effect, and determine the service life and shearing effect of the shear blade. Material selection, processing and heat treatment determine the hardness and sharpness of the blade. So high-quality shearing machine equipped with high-quality blades can maximize production efficiency, reduce labor, and improve shearing quality!