The robotic manipulator is a new type of device developed in the process of mechanization and automation. According to the driving mode, it can be divided into hydraulic type, pneumatic type, electric type and mechanical type.

Robotic arms refer to complex systems with high precision, multiple inputs and multiple outputs, high nonlinearity, and strong coupling. Because of its unique operational flexibility, it has been widely used in industrial assembly, safety and explosion-proof and other fields.

The feature is that it can be programmed to complete a variety of expected operations, and the structure and performance have the advantages of both human and robotic machines. It can save workers, improve efficiency, reduce costs, improve product quality, improve safety, and enhance the image of the factory.

Definition:

A manipulator is an automatic operation device that can imitate certain action functions of human hands and arms to grab, carry objects or operate tools according to a fixed program.

The characteristic is that various expected jobs can be completed by programming. Its structure and performance have the advantages of both human and manipulator arm machines.

Robotic Press Brake Automation

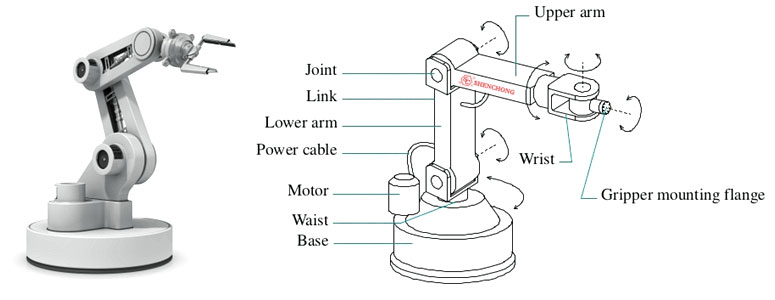

Generally speaking, the manipulator is mainly composed of the following parts:

- Hand or grasping mechanism: including fingers, force transmission mechanism, etc. It mainly plays the role of grasping and placing work

- Transmission mechanism or arm: including wrist, arm, etc.It is mainly used to change the direction and position of objects.

- Driving part: it is the power of the first two parts, so it is also called power source. There are four commonly used driving forms: hydraulic, pneumatic, electric and mechanical.

- Control part: it is the command system of manipulator action. It controls the sequence (program), position and time (even speed and acceleration) of actions.

- Other parts: such as machine body, walking mechanism, stroke detection device and sensing device, etc.

Manipulator can be classified from four aspects: application range, motion coordinate form, driving mode and arm strength.

– Special manipulator

Generally, the special manipulator has only a fixed program without a separate control system. It is subordinate to a machine or production line, which is used to automatically transfer objects or operate a tool.

For example, “sheet metal loading and unloading manipulator“, “automatic punch manipulator”, “laser cutting automatic production line manipulator”, etc.

The manipulator has simple structure and low cost, and is suitable for mass production with simple action.

– Universal manipulator

This refers to a control system with variable programs and separate drives. It is not subordinate to a certain machine and can automatically complete the transfer of objects or operate some mechanical devices.

General manipulators can be divided into two types: simple type and servo type according to their different positioning and control methods.

The simple type is only point control, so it belongs to the program control type. Servo type can be point control or continuous trajectory control, generally belonging to digital control type.

– Rectangular coordinate manipulator

The arm can move along the three directions of the rectangular coordinate axes x, y and Z.

That is, the arm can be retracted back and forth (determined to move along the X direction), moved left and right (determined to move along the Y direction) and lifted up and down (determined to move along the Z direction).

– Cylindrical coordinate manipulator

The arm can move along the X and Z directions of the rectangular coordinate axis and rotate around the Z axis.

That is, the arm can be retracted back and forth, lifted up and down, and rotated left and right.

– Spherical coordinate manipulator

The arm can move along the X direction of the rectangular coordinate axis and rotate around the Y and Z axes.

That is, the arm can be retracted back and forth (moving in the X direction), swing up and down (set to swing around the Y axis) and rotate left and right (still set to rotate around the Z axis).

– Multi joint manipulator

The arm of this manipulator can be divided into small arm and large arm. The connection between the forearm and the boom (elbow) and the connection between the boom and the body (shoulder) are joint (hinge) connections.

That is, the forearm can swing up and down around the elbow, the forearm can swing multi angle around the shoulder, and the arm can also rotate left and right.

- Hydraulic driven manipulator: driven by pressure oil.

- Pneumatic driven manipulator: driven by compressed air.

- Electric drive manipulator: directly driven by an electric motor.

- Mechanical drive manipulator: it is a driving method that transmits the power of the host to the manipulator through cams, connecting rods, gears, intermittent mechanisms, etc.

- The force of micro manipulator is less than 1kg

- The force of small manipulator is 1-10 kg

- The force of medium-sized manipulator is 10-30 kg

- The force of large manipulator is greater than 30kg

Maybe you also want to know: Manipulator Automatic Loading And Unloading Introduction

Manipulator is the earliest industrial robot and the earliest modern robot.

Manipulator can replace people’s heavy labor to realize the mechanization and automation of production. It can operate in harmful environment to protect personal safety.

Therefore, it is widely used in machinery manufacturing, metallurgy, electronics, light industry, atomic energy and other departments.

Robotic manipulators are commonly used as attachments to machine tools or other machines. For example, loading, unloading and transferring work pieces in automatic machine tools or automatic production lines, changing cutting tools in machining centers, etc.

Generally, there is no independent control device. Some operating devices need to be operated directly by people. For example, the master-slave operator used by the atomic energy department to handle dangerous goods is also often called manipulator.

The application of manipulator in forging industry can further develop the production capacity of forging equipment and improve hot, tired and other working conditions.

Manipulator is a new device developed in the process of mechanization and automation.

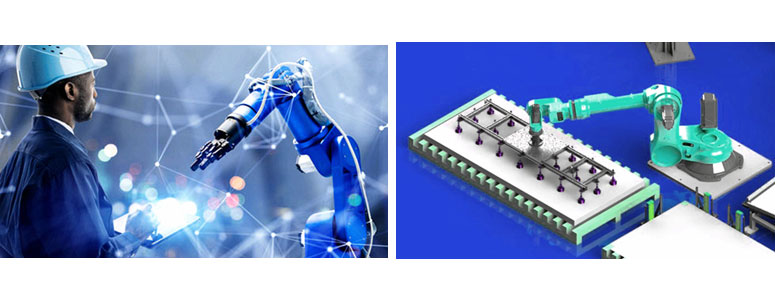

In modern production process, robot manipulator is widely used in automatic production line.

The research and production of robots has become a new technology developed rapidly in the field of high-end technology. It further promotes the development of manipulator and enables manipulator to better realize the organic combination with mechanization and automation.

We cannot simply regard “robot replacing human” as a solution to the difficulty of employment, but the embodiment of the improvement of industrial manufacturing automation, precision and intelligence and product quality.

Although the manipulator is not as flexible as the human hand, it has the characteristics of repeated work and labor, no fatigue, no fear of danger, and the power of grasping heavy objects is greater than that of human hands. Therefore, manipulator has been valued by many departments and has been widely used.

Click here to know: Truss Manipulator Structural Analysis

With the continuous improvement of modern automation, the application of manipulator has become more and more widely.

Manipulator applications:

In the machinery industry, casting, forging, welding, riveting, stamping, heat treatment, machining, assembly, inspection, spraying, electroplating and other processes and types of work have application examples.

It is also used in other industries, such as light industry, construction industry, national defense industry, plastic industry and so on.

In the sheet metal processing industry, the advantages of using robotic manipulator are summarized as follows:

- Improve the automation of the whole production process

The use of manipulator helps to realize the automation of material transmission, workpiece loading and unloading, machining tool replacement and equipment parts assembly, so as to improve labor production efficiency and reduce production cost.

- Improve working environment and avoid potential safety hazards

In the situations of high temperature, high pressure, low temperature, low pressure, dust, noise, odor, radioactive substances or other toxic pollution and narrow operation space, it is dangerous or impossible to take the work piece directly by hand. The application of manipulator can partially or completely replace people to complete the operation safely and effectively.

- Reduce manpower and facilitate efficient production

Human hands are replaced by manipulators for operation, which is an aspect of directly reducing manpower. At the same time, because the manipulator can work continuously, this is the embodiment of reducing manpower of the manipulator.

At present, manipulator is almost applied in automatic CNC machine tools and integrated processing automatic production lines, so as to reduce the accuracy of manpower and production control and facilitate efficient production.

The application of manipulators in the sheet metal industry and the entire manufacturing and processing industry is more and more extensive, and its importance is getting better and better.

In today’s life and production, with the rapid development of science and technology, the biggest difference between robot arm and human arm lies in flexibility and endurance.

The biggest advantage of manipulator is that it can repeat the same action and never feel tired under normal circumstances! The application of manipulator will be more and more widely.

Manipulator is a high-tech automatic production equipment developed in recent decades. The accuracy of work and the ability to complete the task in the environment are very good!