With the rapid development of processing and manufacturing industry, the accuracy and quantity of sheet metal processing are constantly improving to meet the needs of various work pieces in various fields of society.

The products provided by the sheet metal processing industry often have the characteristics of multi variety, multi batch and non-standard. Subsequently, this is also accompanied by the sharp rise in production costs and the shortage of processing capacity.

Therefore, how to coordinate different kinds of production modes with short delivery time and low cost? That is, how to reduce costs and improve efficiency as much as possible on the premise of ensuring product quality is a problem that our employees need to consider and solve.

In the sheet metal processing industry, how to achieve a balance between energy saving and efficiency improvement? We will make the following analysis for you.

In sheet metal manufacturing enterprises, lots of enterprise managers unilaterally pay attention to sheet metal processing accuracy and ability. The common idea is whether a part can be done and whether it can be done well. And they often ignore the cost of processing this part.

At the same time, in the process of compiling the manufacturing technology, the technicians usually pay more attention to the process ability and craftsmanship of the process, which makes the processing method of the parts simpler, the processing speed is faster, and the precision is higher. This will easily lead to waste of personnel, equipment, energy and so on.

In the actual production, due to the particularity of the sheet metal industry itself, many workshop managers usually consider rushing tasks and completing plans, and the workshop will appear: the process of small work pieces arranged on large equipment; multiple equipment activated at the same time to produce the same part, etc. This is undoubtedly a great waste of energy.

Most enterprises prepare process route and process card in strict accordance with the standards. In actual production, we will find that it is good to follow the tradition and rules, but there are still many areas that can be improved in energy and efficiency.

The company’s technical team needs to flexibly apply professional knowledge to solve practical problems. According to the specific work piece, they should constantly optimize the process flow, so as to achieve the effect of minimum energy consumption and maximum output.

Whether bending machine, shearing machine or rolling machine, they have the largest processing range and the highest productivity. Technicians should make the best process route planning according to these equipment, plate information and processing requirements. Reasonable arrangement of processes can reduce the turnover between processes and obviously reduce labor and energy consumption, etc.

In actual production, the enterprise itself will have various constraints:

- The degree of automation is not advanced enough

- Low processing efficiency

- Labor intensive……

This phenomenon can be greatly improved if appropriate tooling is adopted in the design to batch and flow the production work pieces.

In fact, the work of machining workshop equipment is the key and difficult point. In order to improve production efficiency, product quality and actively ensure supply, the staff of the work department often need to work for a long time every day to increase production by increasing production time.

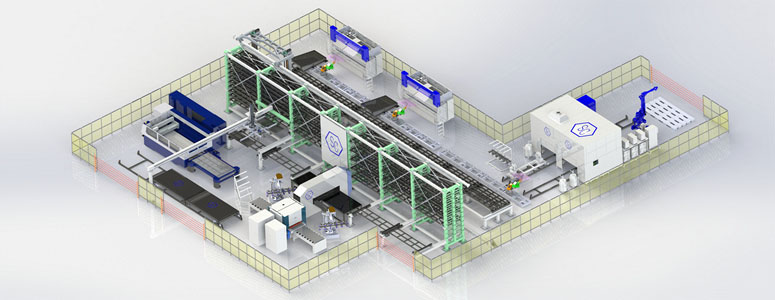

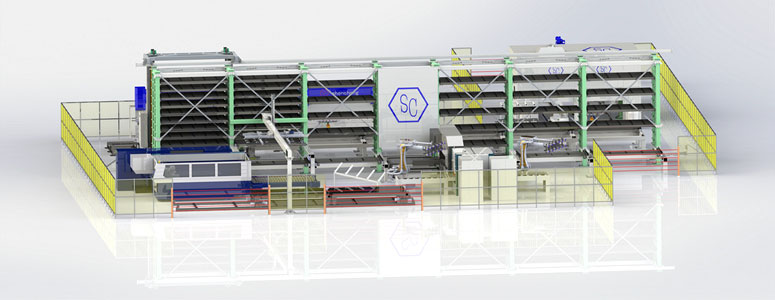

This will lead to unsafe factors and low production efficiency. Therefore, we need to introduce relevant auxiliary tools or invest in robots and automation equipment.

Take the traditional bending process as an example:

When the efficiency of the CNC hydraulic press brake cannot meet the production demand, we should not focus on increasing the working time of workers.

From another perspective, we can install a follow-up auxiliary bending tool or introduce a robotic press brake.

With proper investment in advanced equipment, the company can not only greatly expand production capacity, but also rapidly improve product quality and technical level.

When a processing method cannot fully meet the product requirements, we need to change another method or combine multiple methods.

For example, when the shape of the work piece cut by the plate shearing machine is too single, we can replace it with laser cutting machine. When the straight-line accuracy of laser cutting machine is not enough, we can use CNC plate shearing machine to do straight-line cutting.

Flexible application of various processes and reasonable matching is an effective way to optimize production. This aspect requires us to constantly explore in practice, so as to achieve the balance of energy conservation and efficiency.

Cost and efficiency are always a challenge in the sheet metal processing industry. How to find the balance point requires our constant attention and exploration in practical work? It is believed that as the concept of energy saving, consumption reduction and efficiency improvement is gradually implemented into all aspects of the enterprise’s production, the development of the enterprise will also reach a new height.