CNC brake press have become the most commonly used forging equipment in the bending, edge-folding, and folding of stainless steel plates, iron plates and other metal plates.

The CNC brake press machine can bend some plates of different hardness to keep the bent state and the plate will not be broken. The bending effect of the plate processed by the CNC bending machine is good and will not rebound.

It is widely used in the fields of decoration, electrical appliances and electricity, automobiles and ships, aerospace and so on.

However, as a user, how to run the brake press correctly?

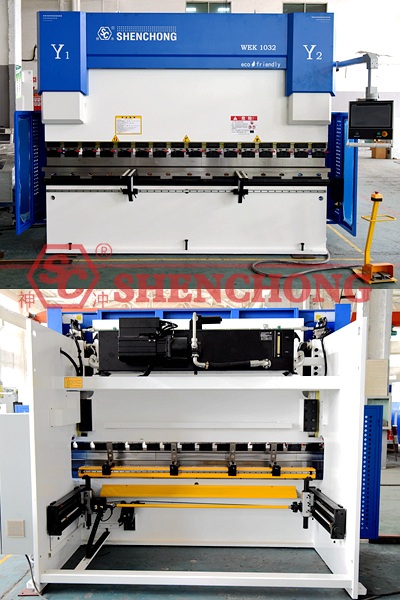

Before running a press brake, we must first understand the components of the machine we are using. Briefly introduce the components of the next bending. The four main components of the bending machine are the slider, the worktable, the synchronization system and the stopper mechanism.

The sliding block adopts hydraulic transmission, and the sliding block part is composed of a sliding block, an oil cylinder and a fine adjustment structure of a mechanical stopper. The left and right oil cylinders are fixed on the frame and the piston (rod) drives the slider to move up and down through hydraulic pressure.

Place the mold on the workbench and perform bending work. It can also be used as a workbench with compensation. The bending angle is compensated mechanically. Improve the accuracy of the workpiece.

The electro-hydraulic synchronous machine is controlled by the hydraulic system, and feedback to the CNC computer through the magnetic scale positioning. The CNC computer controls the hydraulic system to supply oil to realize the synchronization of the cylinders.

The retaining material is driven by a motor, and the two screw rods are driven to move synchronously through a chain or a belt. The numerical control system controls the number of rotations of the motor to control the moving distance of the stopper.

After understanding the main components of the bending machine, I will now briefly introduce how to run the brake press.

- Strictly abide by the safety operation regulations of machine tool workers, and wear labor protection equipment according to the regulations.

- Before starting, carefully check whether the motor, switch, circuit and grounding are normal and firm, and check that the control parts and buttons of the equipment are stuck in the correct position.

- Check the overlap and firmness of the upper and lower molds. check whether the positioning devices meet the requirements of being processed.

- When the upper slide plate and each positioning axis are not at the origin, run the return to origin program.

- After the equipment is started, it runs idling for 1-2 minutes, and moves on the skateboard full stroke 2-3 times. If abnormal sound or malfunction is found, stop immediately, troubleshoot the malfunction, and work after everything is normal.

- When working, one person should be in uniform command, so that the operator and the feeding and suppressing personnel should cooperate closely to ensure that the cooperating personnel are in a safe position before issuing the bending signal.

- When the sheet is bent, it is compacted to prevent the sheet from lifting up and hurting people during bending.

- Cut off the power supply when adjusting the sheet metal press mold, and proceed after stopping the operation.

- When changing the opening of the variable lower mold, no material is allowed to contact the lower mold.

- When the machine tool is working, no one is allowed to stand behind the machine tool.

- It is strictly forbidden to fold the sheet material at one end alone.

- If the workpiece or mold is found to be incorrect during operation, stop and correct it, and it is strictly forbidden to correct it by hand to prevent hand injury.

- It is forbidden to fold over-thick iron plates or quenched steel plates, alloy steels, square steels, and plates that exceed the performance of the plate bending machine to avoid damage to the machine tool.

- Frequently check the overlap of the upper and lower molds. whether the instructions of the pressure gauge meet the regulations.

- Shut down immediately if an abnormality occurs, check the cause and eliminate it in time.

- Before shutting down, place wooden blocks on the lower molds under the cylinders on both sides to lower the upper slide plate onto the wooden blocks.

- Exit the control system program first, and then cut off the power supply.