Industrial production automation is the widespread use of various automatic control, automatic detection and automatic adjustment devices in industrial production to automatically measure, inspect, calculate, control, monitor, etc. the production process to replace humans in manipulating machinery and equipment.

Industrial production automation is a higher stage of production mechanization and one of the basic directions of industrial technology modernization.

According to its development stage, it is divided into:

This is produced partly by manual operation and partly by automatic control.

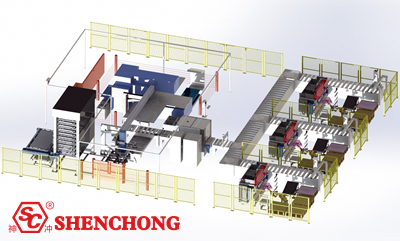

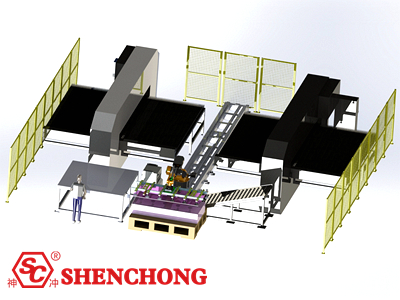

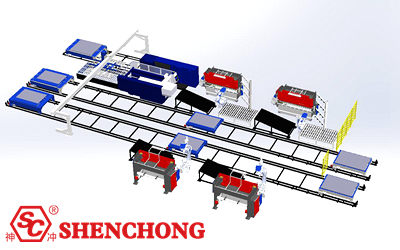

This is also called an automated production line. Refers to the automation of all processes.

Click here to know more about sheet metal automation production line

This is the automation of the entire process from the entry of raw materials to the delivery of products, including processing, packaging, marking, etc. It is also the main content of enterprise management automation.

Industrial production automation can reduce workers' labor intensity and reduce the number of operating workers. Production is continuous and product quality is stable. Labor productivity is high. But the investment costs are relatively high. High energy consumption. It is difficult to change varieties and specifications. It requires a high level of management and cultural and technical quality of workers.

It is generally used in industrial production with advanced product structures, stable processes, large batches, large labor savings, and hazardous production activities.

Industrial automation refers to the use of various advanced technical means to automate and intelligentize various operations in the industrial production process.

With the continuous development of science and technology, industrial automation has gradually become the mainstream trend of modern industrial production. The advantages of industrial automation will be discussed below from multiple perspectives.

Industrial automation can realize the automation and intelligence of the production process, thereby greatly improving production efficiency. Compared with traditional manual operations, automated production can reduce manual intervention, shorten the production cycle, and improve production efficiency. In addition, automated production can also avoid human errors and mechanical failures, thereby further improving production efficiency and stability.

Industrial automation can reduce labor costs and material waste, thereby reducing production costs. Automated production can replace manual operations, reducing labor costs and human errors. In addition, automated production can also achieve precise control of materials and minimize waste, further reducing production costs.

Industrial automation can achieve high-precision and high-stability control of the production process, thereby improving product quality. Automated production can reduce human errors and mechanical failures, and avoid the impact of manual operations on product quality. In addition, automated production also enables precise monitoring and adjustment of the production process to ensure product quality and consistency.

Industrial automation can replace manual operations and avoid workers working in dangerous environments, thus improving work safety. Automated production can prevent workers from being exposed to harmful substances and high-temperature environments, thereby reducing work risks and accident rates.

As market competition intensifies, companies need to continuously improve production efficiency and quality and reduce production costs in order to occupy a dominant position in the market. The wide application of industrial automation can effectively improve the production efficiency and quality of enterprises, reduce production costs, and thereby improve the competitiveness of enterprises.

In short, industrial automation is a modern industrial production method with wide application prospects and important significance. It can improve production efficiency and quality, reduce production costs, improve work safety, and further enhance the competitiveness of enterprises. With the continuous development of science and technology, industrial production automation will be applied in more fields and make greater contributions to the development of modern industry.