With the increase in the processing volume of metal pipes, in order to meet the processing needs of the industrial market, the cutting process of tube laser cutting has become popular in recent years. Various pipe laser cutting machines have successively attracted the attention of users. With the rapid growth of metal tube production and consumption, advanced laser cutting systems have been widely used in the production and processing of pipes, especially stainless steel, alloy steel, carbon steel, and galvanized steel. Processing applications of steel, nickel-titanium alloy, Inconel and other metal tubes.

Laser tube cutting technology is an efficient and automated process that has been widely used in the construction industry. This technology is suitable for cutting various metal pipes, including galvanized steel pipes and stainless steel pipes.

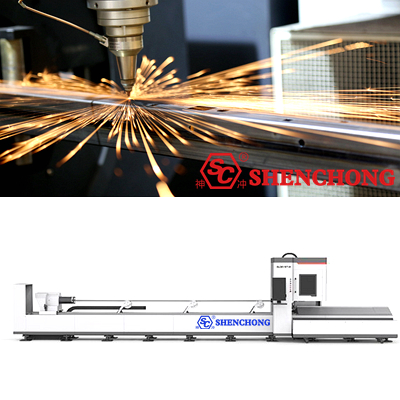

Tube laser cutting machine is also called fiber laser pipe cutting machine. Different from small laser cutting machines, tube laser cutting machines are specially used to cut metal pipes with a certain thickness.

We all know that cutting metal pipes is very difficult and requires extremely large power and processing width. The pipe laser cutting machine has a very large cutting ability for metal, and the metal absorbs this laser tube very strongly. Therefore, for the cutting of metal steel pipes, the pipe laser cutting machine is an indispensable tool.

Let us take a closer look at the product features, application scope and technical advantages of tube laser cutting technologies.

The special laser cutting machine for pipes has unique advantages in cutting tubes. It can perform precise and efficient cutting of various metal pipes in multiple directions, angles and arbitrary graphics. The great advantages in pipe cutting have attracted the attention of many metal tube cutting companies.

Compared with traditional processing equipment such as flame cutting, plasma cutting, and water cutting, laser cutting of metal materials is much more precise. At the same time, different materials may undergo slight expansion and contraction deformation during processing. The laser tube cutting machine can be flexibly adjusted according to these deformations, which is also beyond the reach of many traditional processes.

The fiber laser pipe cutting machine is specially designed for pipe processing customers. It has many advanced features such as easy operation, high degree of automation, high-speed and high-precision cutting, and adaptability to the needs of large-scale industrial production, making it the first choice product in the equipment and pipe processing industry. It has been successfully used in various metal tube processing industries such as fitness equipment, agricultural machinery, residential pipelines, engineering machinery, vehicle manufacturing, special vehicles, and electrical appliance manufacturing.

- Powerful cutting function: can cut square tubes, round tubes, rectangular tubes and various special-shaped tubes.

- Adopting a rack and pinion transmission structure, pneumatic clamping chuck, and rotation-propelled pipe cutting method, it has high centering accuracy and processing accuracy.

- The machine tool is annealed to eliminate internal stress and then finished, which better solves the stress caused by welding and processing, thus improving the rigidity and stability of the equipment. Better stability and longer service life.

- Excellent processing system, friendly interface, easy to operate, and can provide real-time feedback on the processing status, ensuring orderly processing.

The cutting process of laser pipe cutting machine is smoother than traditional cutting process, and the cut pipe can be directly used for welding, reducing the processing steps in the industry. Compared to traditional pipe processing that requires cutting, punching, and bending processes, traditional pipe processing processes consume a large amount of molds. Laser cutting of tubes not only has fewer processes, higher efficiency, and better quality of the cut workpiece, but also has great market development space.

Laser cutting tubes can be automatically cut by borrowing computer-aided design software for graphic design and importing it into the cutting machine operating system. Usually, an operating system includes a database with key information such as the material type, thickness, and geometric shape of the pipe.

The truly unique feature of laser pipe cutting machines is their cutting accuracy, which uses chuck and push cutting methods with high centering and processing accuracy. Due to the improvement of modern laser cutting machines, industrial manufacturing applications involving small diameter pipes have been greatly accelerated. Laser pipe cutting machines can make corresponding adjustments based on these deformations to ensure the accuracy of tube cutting, which is not achievable by many traditional processes.

A professional fiber laser pipe cutting machine can replace traditional mechanical designs such as drilling, milling, sawing, stamping, or cleaning burrs. It can achieve complex pipe structure cutting, chamfering, grooving or hole cutting, and engraving based on the processing procedures of different equipment and hard tools that affect metal pipe processing.

click here to know Applications And Advantages Of Tube & Pipe Laser Cutting Machines

Fiber laser pipe cutting machine can be used to cut various types of pipes such as round pipes, elliptical pipes, square pipes, rectangular pipes, and irregular pipes, as well as various materials such as copper. Widely applicable industries include various tube processing industries such as fitness equipment, petroleum pipelines, construction machinery, automobile manufacturing, and household appliance manufacturing.

Regardless of the shape of the tube, it can be efficiently and accurately cut. The laser cutting machine for tubes has quickly occupied various metal processing industries with its professional and stable cutting effects, especially in the fields of automobile manufacturing, oil extraction, mechanical manufacturing, etc. It has been widely used.

In recent years, the application of pipelines in sanitary ware and furniture has attracted special attention from people. Previously, tubes such as stainless steel, aluminum, and copper were commonly used in office furniture and building materials. Due to its simple, beautiful, durable, and easy to clean characteristics, it has gradually become a new favorite of modern smart homes in China.

Traditional pipe processing involves at least 8-9 processes, including coupling materials, sawing, CNC machining, bevel machining, sampling, punching, drilling, bending, cleaning, and welding. The complex processing process, low processing accuracy, and high waste rate lead to low efficiency in metal pipe processing and low economic benefits for the factory. These are all pain points for a metal tube processing enterprise. In order to further increase production efficiency, improve processing quality, and reduce material waste in the pipe industry, metal fiber laser pipe cutting machines have become the winning weapon for various metal tube manufacturers.

Laser tube cutting technology is an efficient and automated process that has been widely used in the construction industry. This technology is suitable for cutting various metal pipes, including galvanized steel pipes and stainless steel pipes. High precision, high efficiency, and strong flexibility are the biggest advantages of laser tube cutting technology.

In the future, the laser tube cutting machine industry will tend to develop towards informatization, efficiency, and environmental protection. Therefore, it is necessary to strengthen the strategic positioning guidance for the laser tube cutting machine industry, in order to promote enterprise scale development, improve efficiency, informatization, and intelligence, and better meet market development needs. The demand for pipes will continue to increase in the future, and the improvement of processing accuracy and production efficiency is a necessary condition for the rapid development of professional laser pipe cutting machines.