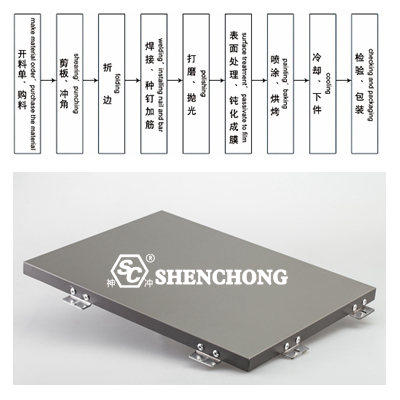

Aluminum veneer refers to a building decoration material that is processed by chromium treatment and then using fluorocarbon spraying technology. The production of aluminum veneer is divided into two major steps: sheet metal processing and spraying.

Only with complete equipment for shearing, punching, bending and rolling can we realize the processing of aluminum veneers of various complex shapes in basic sizes. Aluminum argon arc welding and high-frequency nail welding equipment can ensure high-quality completion of the welding, corner sealing and reinforcement nailing processes of formed aluminum plates. The spray booth and oven can complete the processing of extremely large plates, ensuring that the product surface meets the film layer requirements of the base material required for coating.

Aluminum veneer refers to chromating the aluminum material first, so that a protective film is formed on the surface of the aluminum material. Then spray fluorocarbon paint to make the aluminum veneer have better corrosion resistance, oxidation resistance, heat resistance, cold resistance and other properties, and finally process it into applicable building decoration materials.

The generated aluminum veneer can not only resist acidic and alkaline items, such as acid rain, salt spray and other air pollutants, but also resist strong ultraviolet radiation. Therefore, aluminum veneers are mostly used in buildings and construction. They can not only remain color-fast, but also can be used for a long time and have a long life.

The first step is sheet metal processing. This process mainly involves cutting, bending, arc bending, welding, grinding and other processes on the flat plate. Process the aluminum veneer into the shape and size required for construction.

The second step is to spray. Spraying is to spray paint on the processed sheet metal.

Equipped with complete shearing, punching, bending equipment and rolling machines for processing curved plates, it can realize sheet metal processing of various complex shapes with a basic size of 4 meters. Many manufacturers can achieve processing of more than 6 meters. But the longer the length, the worse the flatness.

For large-format aluminum veneer bending, we can use a bending machine equipped with a follower device. Very convenient and fast. Prioritize improving bending accuracy and saving manpower!

Video Case Show: Press Brake Sheet Follower Bending Aluminum Veneer 9mm

Aluminum argon arc welding and high-frequency nail welding equipment can ensure high-quality completion of the welding, corner sealing and reinforcement nailing processes of formed aluminum plates.

Chemical pretreatment uses chemical solutions to remove organic and inorganic stains on metal surfaces. Then remove the natural oxide layer. Chemical agents are then used to create an oxide film to produce rust prevention and long-lasting paint adhesion on the metal surface. Electrostatic coating uses domestically advanced automatic electrostatic spraying lines to spray fluorocarbon coatings layer by layer on the metal base surface according to process requirements, and bake and solidify according to specific temperatures and times.

Aluminum veneer is widely used and its usage rate is very high in the construction industry. Aluminum veneers often appear in daily life scenes. We only need to use sheet metal processing equipment to cut and form them, and these panels can be used in the construction and decoration industries.

Aluminum veneer curtain wall is suitable for decoration of various building interior and exterior walls, lobby facades, column decorations, elevated corridors, pedestrian bridges, elevator edging, balcony packaging, advertising signs, indoor special-shaped ceilings, etc. Building exterior walls, beams and columns, balconies, awnings, airports, stations, hospital conference halls, opera houses, stadiums and reception halls and other high-rise buildings.

Aluminum veneer is a kind of decoration material, often suitable for indoor decoration. Such as being used in the decoration of various lobby facades, ceilings, balcony packaging, billboards, door headers, etc. Major manufacturers use CNC bending machines to bend aluminum veneers, which can then be used to manufacture doors, windows, curtain walls, elevators, etc.

This material can be used in halls, corridors, balconies, elevators and other spatial locations to facilitate exhaust heat dissipation. Moreover, aluminum veneer is light in weight, high in strength, and has good tensile toughness. It can remain color-fast all year round and is highly practical for decoration.

Aluminum veneer is also a new type of material, often used in construction projects. Such as used in building exterior walls, shopping malls, hotels, public places, sports venues and other high-rise buildings.

Aluminum veneers can be installed flexibly, and the height and spacing can be adjusted as needed, and can be used in conjunction with central air conditioning, lighting and other facilities to improve the overall utilization of space. Manufacturers use CNC hydraulic shearing machines to quickly and easily cut aluminum plates into raw materials of different sizes for use in actual construction.

At the same time, aluminum veneer is not easy to get dirty, and it is difficult for pollutants to adhere to the surface. When used in hotels, public places, shopping malls and other places, it is very convenient for cleaning and maintenance.

Aluminum veneers are used in various scenarios, which are also due to the following characteristics of aluminum veneers.

Compared with other materials, aluminum veneer has a simple structure. The installation and connection are particularly convenient. At the construction site, it can be installed quickly without cutting, which provides great convenience for construction.

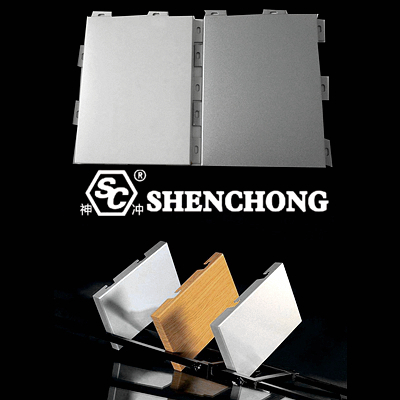

Aluminum veneer materials have good process performance, and the surface can be sprayed in a variety of colors. It can also be formed into various patterns as required, or combined with other materials to create different appearances. The processing techniques are diverse and the colors are richer.

Aluminum veneers are connected through keels, making them safer and more reliable when used in high-rise buildings, and are less likely to be damaged and difficult to repair if they fall. And the materials used can be recycled and reused, which is more conducive to environmental protection.

Now, in the face of the rapid changes in the market environment, aluminum veneer still contributes to the rapid development of the aluminum veneer industry with its many advantages. For the choice of aluminum veneer, grasping the decoration trend and consumer demand is the core of the product. Green, energy-saving, and environmental protection will also be the new development direction of the aluminum veneer industry in the future.

Aluminum veneer manufacturers can also improve the performance of processing equipment to improve their product quality and production efficiency. Purchasing SC hybrid servo CNC press brake can carry out low-noise aluminum veneer bending production and processing activities in a green and environmentally friendly manner.