Sheet metal laser drilling is a thermophysical process of interaction between laser and material. It is determined by the characteristics of the laser beam (including wavelength, pulse width, beam divergence angle, focusing state, etc.) and many thermophysical properties of the material.

Laser drilling technology uses a high-power density laser beam to irradiate the processed material, causing the material to be quickly heated to the vaporization temperature and then evaporated to form holes.

Laser drilling is the earliest practical laser processing technology and one of the main application areas of laser processing. It is classified as laser removal in laser processing, also known as evaporation processing.

With the rapid development of modern industry and science and technology, more and more materials with high hardness and melting point are being used, and traditional processing methods can no longer meet certain process requirements.

① Laser drilling has fast speed, high efficiency, and good economic benefits.

② Laser drilling can achieve a large aspect ratio.

③ Laser drilling can be performed on various materials such as hard, brittle, and soft.

④ Laser drilling has no tool loss.

⑤ Laser drilling is suitable for processing large quantities and high-density group holes.

⑥ Laser can be used to machine small holes on inclined surfaces of difficult to machine materials.

Laser can not only drill holes but also cut sheets. Click here to learn more about CNC Laser Cutting Machine

Laser drilling is one of the earliest practical laser processing techniques and one of the main application areas of laser processing.

The traditional processing methods for materials with high hardness and melting point can no longer meet certain process requirements. This type of machining task is difficult, sometimes even impossible, using conventional mechanical processing methods. It is not difficult to achieve laser drilling.

The laser beam is highly concentrated in space and time. By focusing with a lens, the diameter of the spot can be reduced to micrometers, resulting in a yield of 105-1015W/cm². The laser power density. Such a high power density can almost be used for laser drilling in any material.

Moreover, compared with other conventional drilling methods such as mechanical drilling and electrical discharge machining, it has the following significant advantages: fast speed, high efficiency, and good economic benefits.

Due to the fact that laser drilling utilizes a power density of 107-109W/cm². The high-energy laser beam exerts instantaneous effects on the material. Therefore, the laser drilling speed is very fast.

By combining high-efficiency lasers with high-precision machine tools and control systems, and using microprocessors for program control, efficient drilling can be achieved. Compared with electrical discharge drilling or mechanical drilling, laser drilling improves efficiency by 10-1000 times on different workpieces.

Due to the high energy and focus characteristics of lasers, laser drilling technology is widely used in many industrial processing processes, making it easier to process materials with high hardness and melting point.

For example, machining micrometer sized aperture on high melting point metal molybdenum plates. Process small holes of tens of micrometers on hard tungsten carbide. Processing deep holes of several hundred micrometers on red and sapphire, as well as diamond drawing molds and chemical fiber nozzles.

By utilizing the highly concentrated characteristics of laser in space and time, the diameter of the spot can be easily reduced to the micrometer level, resulting in a yield of 100-1000W/cm². The laser power density. Such a high power density can almost be used for laser drilling in any material.

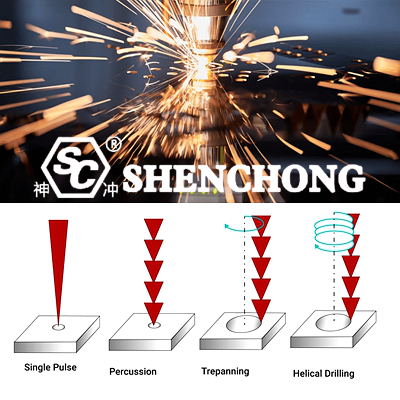

Piercing method is one of the most commonly used methods in laser drilling. It mainly sprays materials by instantaneously heating them to form pores.

The perforation method is suitable for the large aperture required by laser technology. Different beam sizes and power densities can be selected based on the aperture size. When using the perforation method, it is important to note that the laser pulse frequency should match the material thickness and laser power.

Advantages: Fast speed and wide applicability.

Disadvantage: It needs to meet certain power density and pulse frequency conditions. The drilling effect on thicker materials is not satisfactory. And it is easy to produce chamfers.

The thermal explosion method utilizes the instantaneous heating of the laser to rapidly expand and contract the material, breaking it to form pores.

The thermal explosion method is suitable for thinner materials, such as quartz glass, and can be used to create various shapes of pores.

Advantages: It can create holes of various shapes.

Disadvantage: The scope of application is relatively narrow. Only suitable for thinner materials.

Jet method uses laser to instantly heat materials, causing them to rapidly expand and contract, thereby spraying out high-temperature airflow. The airflow instantly impacts the material, achieving the effect of punching holes. The use of jet drilling can result in smooth hole walls and burr free holes.

Advantages: The quality of the holes is high, and there is no residue around the holes.

Disadvantage: Requires higher power. And it is only applicable to materials such as metals and plastics.

The melting method can be used to melt materials through laser heating, thereby forming pores. The melting method can be applied to various materials, such as metals, ceramics, semiconductor materials, etc. When using the melting method, it is necessary to adjust the laser processing parameters based on the material's melting point and laser power.

Advantages: It has a wide range of applications and can handle various materials.

Disadvantage: Bubbles are easily generated during the melting process, which affects the quality of the pores.

The above four drilling methods can achieve high precision drilling and have a wide application prospect. Each drilling method has its own limitations such as applicable materials, pore size and accuracy. In the practical application process, we should choose the most suitable drilling method according to the specific situation to achieve the best processing effect.