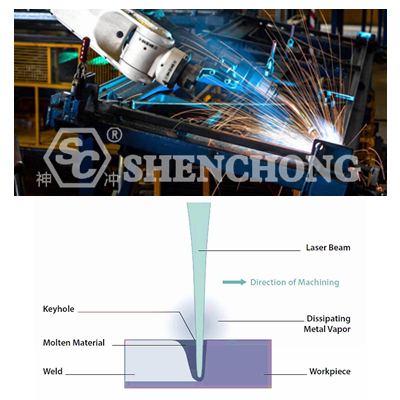

Laser is a new energy source that can achieve processing methods such as welding and cutting, and is one of the most advanced manufacturing processes. The laser welding machine uses laser as the energy source and integrates multiple functions, with a wide range of applications.

At present, laser welding machines can be seen in various industries, from aerospace to shipbuilding industry, as well as in industries such as automotive parts, biomedical, hardware manufacturing, jewelry, etc. Laser welding machines have been widely used.

Laser welding machines use the enormous energy of laser pulses to heat the materials that need to be processed in a small range, ultimately melting them to form a specific molten pool. They can achieve spot welding, butt welding, overlap welding, seal welding, etc. With their unique advantages, they have opened up a new application field of laser welding, providing precision welding for thin-walled materials and small parts.

Laser welding machines can repair defects such as wear, defects, scratches in molds, as well as sand holes, cracks, and deformations in metal work pieces.

If the dies is used for a long time, it will wear and tear. If it is directly discarded and the loss is significant, the problematic mold can be fully utilized again through repair using a laser welding machine. Especially when repairing fine surfaces, the two processes of thermal strain and post weld treatment are avoided, greatly saving production time and costs.

Laser cutting is a new cutting method that uses laser welding machines to cut materials such as stainless steel, copper, aluminum, zirconium, and their alloys. In addition, it can also cut non-metallic materials such as plastic, rubber, wood, etc. It is another important application of laser welding machines in material processing.

With the continuous reform and replacement of laser welding machines, their functions have become more and more diverse. They can not only weld and cut, but also clean and remove rust. Laser welding machines use the beam of light emitted by the laser to remove the contaminated layer on the surface of the processed work piece.

Using a laser welding machine for cleaning has the characteristic of non-contact and does not require cleaning fluid, which can replace professional cleaning equipment.

The main purpose of laser welding machines is undoubtedly welding. They can not only weld thin-walled metal materials such as stainless steel plates, aluminum plates, galvanized plates, but also be used for welding sheet metal parts, such as kitchen utensils. They are suitable for welding flat, straight, curved, and any shape, and are widely used in industries such as precision machinery, jewelry, electronic components, batteries, clocks, communication, handicrafts, etc. They can complete welding well in various complex environments, High production efficiency, with more obvious advantages compared to traditional argon arc welding, electric welding and other processes.

Using a laser welding machine, the welding seam width is small, the depth is large, the thermal impact area is small, the deformation is small, the welding seam is smooth and beautiful, the welding quality is high, there are no pores, it can be accurately controlled, the welding quality is stable, and there is no need for treatment or simple treatment after welding.

The laser welding machine is suitable for welding mold steel models such as S136, SKD-11, NAK808407718738, H13, P20, W3022344, and has a good welding effect.

Carbon steel is welded using a laser welding machine with good results, and the quality of its welding depends on the content of impurities. In order to achieve good welding quality, preheating is required when the carbon content exceeds 0.25%.

When steels with different carbon contents are welded to each other, the welding torch can be slightly tilted towards the side of low-carbon materials to ensure joint quality.

Due to the extremely fast heating and cooling rates during laser welding, when welding carbon steel. As the carbon content increases, the sensitivity of welding cracks and notches also increases. Both medium and high carbon steel and ordinary alloy steel can undergo good laser welding, but preheating and post welding treatment are required to eliminate stress and avoid crack formation.

In general, stainless steel welding is easier to obtain high-quality joints than conventional welding. Due to the high welding speed and small heat affected zone of laser welding, the adverse effects of overheating and large linear expansion coefficient during stainless steel welding are alleviated, and the weld seam is free of defects such as pores and inclusions.

Compared with carbon steel, stainless steel is easier to obtain deep penetration narrow welds due to its low thermal conductivity, high energy absorption rate, and melting efficiency. By using low-power laser welding to weld thin plates, joints with good appearance and smooth and beautiful welds can be obtained.

Welding copper and copper alloys is prone to issues of incomplete fusion and incomplete penetration, so energy concentrated, high-power heat sources should be used in conjunction with preheating measures

When the thickness of the workpiece is thin or the structural stiffness is small, and there are no measures to prevent deformation, it is easy to generate significant deformation after welding. However, when the welded joint is subject to significant rigid constraints, welding stress is prone to occur

When welding copper and copper alloys, thermal cracks are also prone to occur, and porosity is a common defect during copper and copper alloy welding.

Almost all thermoplastic and thermoplastic elastomers can use laser welding technology. Commonly used welding materials include PP, PS, PC, ABS, polyamide, PMMA, polyoxymethylene, PET, and PBT. However, some other engineering plastics, such as polyphenylene sulfide PPS and liquid crystal polymers, cannot directly use laser welding technology due to their low laser transmittance. Generally, carbon black is added to the underlying material to absorb sufficient energy and meet the requirements of laser transmission welding for welding.

Laser welding of low alloy high-strength steel can obtain joints with mechanical properties equivalent to the base material as long as the welding parameters are selected appropriately.

HY-130 steel is a typical low alloy high-strength steel that has undergone quenching and tempering treatment, which has high strength and high crack resistance. When welding using conventional welding methods, the weld seam and HAZ structure are a combination of coarse grains, partially fine grains, and the original structure. The toughness and cracking resistance of the joint are much worse than those of the base metal, and the weld seam and HAZ metal structure are particularly sensitive to cold cracking in the welded state.

- Laser welding machine has high output energy and fast welding speed.

- Laser welding machines have high accuracy and strong adaptability, and can be used for giant and micro welding.

- Laser welding machines can be used for mass production, saving manpower and resources.

Laser welding machines have significant advantages and have contributed actively to various fields, promoting the rapid development of the welding industry.

The mechanical manufacturing industry not only has huge equipment, but welding is also difficult, and there are safety hazards in the welding process. Laser welding machines can avoid manual contact and solve the entire process automation, becoming a true "welding" expert in the mechanical manufacturing industry and highly popular.

As a commonly used means of transportation, automobiles have higher requirements for the appearance after welding. The use of laser welding machines can achieve fast welding, full welds, firm welding, simple cleaning, and better meet the production requirements of high-end products.

Electronic equipment, as an essential tool for modern life, work, and learning, is difficult to weld due to its small size but high requirements. Laser welding can break space limitations and freely switch welding angles to ensure welding quality.

Jewelry is precious and exquisite. Laser welding machines magnify small parts of jewelry through a microscope, achieving precision welding without deformation after repair, solving the two major problems of weld aesthetics and welding quality, and becoming essential welding equipment.

In aerospace, there are many components and parts involved in the body, so welding requirements are also very high. Laser welding not only allows for flexible parameter setting, but also enables precise welding, especially for equipment and facilities with complex structures.