Carriage panel refers to the plate used for interior decoration and isolation of the carriage. So how is the carriage panel processed and manufactured?

Carriage board is a panel used for different vehicle types such as rail trains, passenger cars, freight cars, and special vehicles. According to functional characteristics, it is divided into: anti slip carriage panel, fireproof carriage panel, and waterproof carriage panel.

The manufacturing process mainly includes material preparation, cutting, finishing, forming, splicing and assembly, and surface treatment.

The commonly used materials for carriage panels include plywood, medium density fiberpanel (MDF), solid wood panel, etc.

Before processing, the material must first be inspected to ensure its quality is qualified. At the same time, material selection and procurement should be carried out according to design requirements to meet the usage needs of carriage panels.

In the initial stage of carriage plate processing, it is necessary to cut the materials.

First, the material is cut to the required size according to the design drawings and size requirements. This step can use traditional hand cutting tools, or it can be using CNC cutting equipment to improve production efficiency and accuracy.

According to the size, material, and different processing requirements of the panel, manufacturers can choose various cutting equipment. Common plate cutting equipment includes NC/CNC hydraulic guillotine shear machines, laser cutting machines, water jets, flame cutting machines, etc. Different cutting equipment is suitable for different needs.

Transportation Industry Automatic Plate Shearing Machine 8X2500MM

After cutting, there will be irregular and rough parts on the edge of the carriage board, which need to be repaired and processed. This step mainly includes two steps: trimming and polishing.

Trimming refers to trimming the edges of a sheet into straight or curved lines and maintaining flatness. Polishing refers to the use of tools such as sandpaper or grinding wheel to polish the surface of a panel to remove burrs, bumps, and stains, making it smoother.

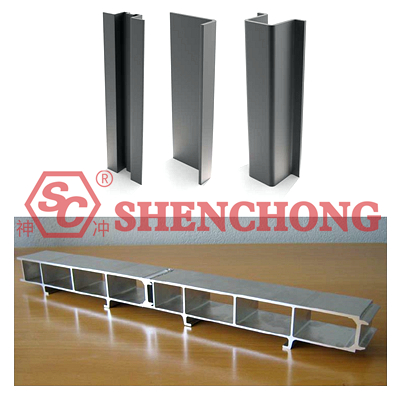

After finishing the appropriately sized carriage panel, various forming processes need to be carried out to produce the workpiece in the drawing.

Curved interior decorative boards need to be rolled using a plate rolling machine. Some angled sheets can be bent using a bending machine or roll forming machine. Different shapes of plates require different forming and processing equipment to be selected, and we need to plan according to the workpiece drawings.

The splicing and assembly of carriage panels involves connecting multiple panels according to design requirements to form an overall structure.

Common splicing methods include mortise and tenon joints, mortise and tenon joints, and bolt connections. During the splicing process, it is necessary to pay attention to the alignment and stability between the panels to ensure the firmness and stability of the carriage panels.

The surface treatment of the carriage plate is to increase its wear resistance, waterproofing, and decorative effect. Common surface treatment methods include painting, veneer, and painting.

Spray painting is the process of spraying paint onto the surface of a panel to form a protective film. Veneer is the process of applying a wood grain film to the surface of a panel to enhance its decorative effect. Painting is the process of applying paint to the surface of a panel, forming a protective film that can be selected in different colors and glosses.

After the processing of the carriage panel is completed, quality inspection is required to ensure that the product meets the design requirements and standards.

Quality inspection mainly includes aspects such as appearance quality, dimensional accuracy, surface smoothness, and connection stability. For unqualified carriage panels, rework or replacement is required to ensure product quality and safety.

The carriage panels that have passed the quality inspection need to be packaged and shipped out of the factory. Packaging can choose to use materials such as wooden boxes, pallets, or packaging films to protect the carriage board from external environmental influences.

During the packaging process, it is also necessary to label information such as product name, specifications and dimensions, production batch number, and production date to facilitate product traceability and management.