Digital sheet metal factory refers to the use of digital technologies (such as automation, Internet of Things, cloud computing, big data, artificial intelligence, etc.) to improve the efficiency, precision and flexibility of sheet metal manufacturing processes. Through these technologies, sheet metal factories can optimize production processes, rationally allocate resources and monitor in real time, thereby reducing human intervention, improving production efficiency and reducing costs.

The core features of digital sheet metal factory usually include: intelligent production, real-time data collection and monitoring, big data analysis and optimization, customized production, cloud platform collaboration and virtual simulation and optimization. These digital transformations enable sheet metal factories to improve production capacity while enhancing their adaptability to market changes, and to respond more flexibly to challenges in order changes, quality control and production management.

A digital sheet metal factory uses advanced digital technology, automated equipment and information management methods to comprehensively transform and optimize the production methods, management models and operation processes of traditional sheet metal manufacturing factories. Its purpose is to improve production efficiency, reduce costs, improve product quality and enhance the flexibility and sustainability of the factory through data-driven, intelligent control and efficient production processes.

Specifically, the characteristics of digital sheet metal factories include:

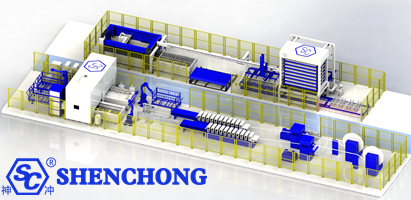

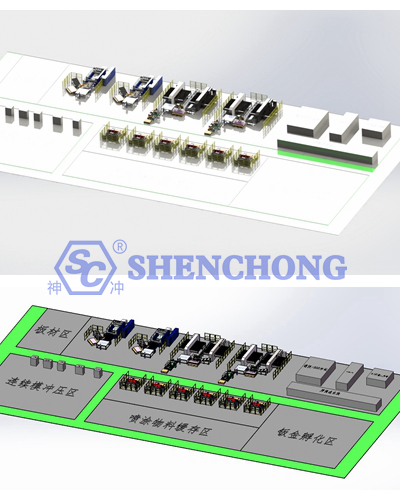

Using robots, automated production lines, CNC equipment and other technologies to perform precise sheet metal processing, such as cutting, bending, stamping, welding, etc. The equipment can be interconnected and automatically adjust the production process.

Design and optimize products through computer-aided design (CAD) and computer-aided manufacturing (CAM) systems, and simulate the production process using virtual simulation technology, thereby reducing design errors and waste in production.

Real-time data collection and analysis: Through sensors, the Internet of Things and other technologies, every link of the production line is monitored in real time, data is collected and analyzed to help managers adjust production plans in a timely manner, predict equipment failures, and ensure efficient operation of the production line.

Through cloud computing technology, the factory's production data, equipment status, inventory information, etc. are centrally managed. Different departments and factories can share information and work together to improve the flexibility and efficiency of production scheduling.

Digital factories can quickly respond to customers' customized needs, support small batch and multi-variety production, and maintain high production efficiency and quality.

Through digital tools, lean management is carried out in all aspects of production to reduce waste and improve resource utilization. At the same time, the quality inspection system can monitor product quality in real time to ensure that every product leaving the factory meets the standards.

In summary, the digital sheet metal factory uses intelligent and information-based means to comprehensively improve production efficiency, product quality and management level, and can better respond to the rapid changes and personalized needs of the market. This transformation helps companies achieve lower-cost and more efficient production while improving their competitiveness.

The advantages and features of digital sheet metal factory are mainly reflected in the following aspects:

Automated production: Digital sheet metal factories use advanced automated equipment (such as CNC laser cutting machines, robot bending, automated welding, etc.), which reduces the complexity and errors of manual operations and significantly improves production efficiency and consistency.

Quick response: Through digital design and manufacturing systems (such as CAD/CAM), it is possible to quickly switch from design to production, shortening product development and production cycles.

Flexible production: Digital sheet metal factory can easily switch production modes for different products, support small batch and multi-variety production, and meet customers' personalized customization needs.

Real-time adjustment of production plans: Through real-time data collection and analysis, managers can flexibly adjust production plans and make dynamic adjustments based on order requirements and production progress, avoiding delays and waste in traditional production.

Precision processing: The CNC equipment in digital sheet metal factories is highly accurate and can ensure the accuracy of the processing quality and size of each workpiece.

Intelligent detection and monitoring: Combined with sensors, the Internet of Things and other technologies, every link in the production process can be monitored for quality in real time, potential quality problems can be discovered in advance, and the occurrence of defective and waste products can be reduced.

Big data analysis: By analyzing historical data, factories can discover potential causes of quality fluctuations and take improvement measures to further improve product stability and consistency.

Reduce labor costs: Automated equipment replaces a large number of manual operations, reduces labor costs, and reduces waste caused by human errors.

Resource optimization: Through the digital management system, the use of various resources (such as materials, energy, equipment time, etc.) in the production process can be optimized, thereby effectively reducing costs.

Reduce inventory and logistics costs: Digital sheet metal factory usually adopt lean production methods, which can accurately schedule production according to demand, avoid overproduction, and reduce inventory pressure and storage costs.

Real-time monitoring: Through the connection of the Internet of Things and cloud platforms, real-time data of the production line (such as equipment status, production progress, quality inspection, etc.) can be displayed in real time on the management platform, allowing managers to quickly understand the production situation.

Data analysis supports decision-making: Using big data analysis, management can make more scientific and reasonable production decisions, inventory management decisions, and resource scheduling based on accurate historical data and trend forecasts.

Faster market response speed: Digital sheet metal factory can quickly respond to changes in market demand, quickly design and manufacture customized products, and take the lead in a highly competitive market environment.

Quality and delivery guarantee: Stable product quality and on-time delivery can improve customer satisfaction, enhance customer loyalty, and promote the long-term development of the enterprise.

Energy and resource conservation: Through digital management, energy consumption and resource usage can be monitored in real time, thereby optimizing the production process, reducing waste, improving resource utilization, and supporting environmental protection.

Reducing waste and pollution: High-precision digital equipment can reduce waste during processing, and at the same time can achieve more environmentally friendly processing methods and reduce the impact on the environment.

Technology update and upgrade: Digital sheet metal factories rely on advanced digital platforms to facilitate technology updates and iterations. For example, new smart devices, software updates, data analysis model optimization, etc. can be quickly integrated into existing systems to help factories maintain technological foresight.

Employee skill improvement: In the process of digital transformation, employee skill training and technical support are also improved, which will help companies continue to adapt to new technologies and market demands in the future.

Supply chain transparency: Digital factories can exchange real-time data with suppliers, distributors and other parties through information sharing platforms to improve the response speed and accuracy of the supply chain.

Accurate procurement and inventory management: With the help of real-time data analysis, raw material demand can be predicted more accurately, procurement plans can be optimized, and inventory costs can be reduced.

With highly integrated technologies such as artificial intelligence, the Internet of Things, and cloud computing, the factory's operation is more intelligent and automated.

The design and production of digital sheet metal factories are completely controlled and optimized through digital platforms, allowing product quality and production processes to be finely managed.

Able to respond to diverse and customized production needs and efficiently adjust production plans.

Data from the entire production process can be collected and analyzed, providing strong support for management decisions.

Digital sheet metal factories not only improve production efficiency and quality, but also enable companies to maintain flexibility and continuous innovation capabilities in the fierce market competition.

The development trend of digital sheet metal factories shows a more and more intelligent, automated, flexible, green and integrated direction. These trends are driving the transformation of the sheet metal manufacturing industry from traditional models to modern manufacturing. The following are some of the main development trends:

With the application of artificial intelligence (AI) and machine learning technology, sheet metal factory will gradually realize the transformation from automation to intelligence. Intelligent equipment can not only complete traditional mechanical processing tasks, but also improve production efficiency and precision through self-learning and optimization.

More and more sheet metal factories will deploy more sensors and networked devices to form an interconnected production environment. Through the industrial Internet, equipment, tools, raw materials and personnel can collaborate in real time, and the production process can be managed more accurately and dynamically.

The market demand for customized products is increasing, and digital sheet metal factories can quickly switch production modes to support personalized and customized production. Through a highly integrated digital platform, factories can flexibly adjust production plans to meet small-batch, high-variability market demands.

Future sheet metal factories will pay more attention to production flexibility, be able to respond to order changes in real time, ensure that production plans can be adjusted in the shortest time, reduce production cycles, and increase delivery speed.

With the advancement of digital transformation, all aspects of sheet metal factories, such as design, manufacturing, quality control, production scheduling, and logistics, will be digitalized and managed in an information-based manner. This integrated digital process can not only improve production efficiency, but also ensure the transparency and traceability of information.

Digital twin technology will simulate and optimize the production process in real time by creating virtual models of factories and production lines. This technology can not only detect potential problems in the design stage, but also monitor and adjust the process in real time during the production process to ensure the stability and quality of production.

Through big data analysis, factories can predict equipment failures and avoid downtime losses. At the same time, AI algorithms can analyze production data, optimize production plans and scheduling, reduce energy waste, and improve resource utilization.

Artificial intelligence will gradually be added to production decisions, combining real-time data and historical data for intelligent analysis, supporting automated production adjustments, quality control, and inventory management.

Digital sheet metal factories will achieve higher efficiency in energy management, adopt more energy-saving equipment and technologies, and reduce energy consumption and carbon emissions. At the same time, digital technology can also optimize resource allocation and reduce raw material waste.

With the strengthening of environmental protection policies, digital sheet metal factories will adopt more environmentally friendly production processes and materials. Waste recycling, low pollution emissions, and recycling will become development trends.

With the development of 3D printing technology, sheet metal factories may gradually adopt additive manufacturing technology to produce complex sheet metal parts, especially for small batch production and complex structural parts, 3D printing can provide higher design freedom and lower material waste.

Digital sheet metal factories will combine traditional processing methods with additive manufacturing technology to promote innovation in production processes, especially in the fields of mold manufacturing and prototype design.

More and more sheet metal factories will use cloud computing technology to achieve real-time sharing and storage of production data, making collaboration between different factories and departments more efficient. Supply chain management, production scheduling, inventory management, etc. can achieve global collaboration through cloud platforms.

The combination of cloud platforms and the Internet of Things will enable enterprises to remotely monitor the operation status of factories, adjust the production process in real time, reduce the dependence on on-site personnel, and achieve resource sharing between factories in different regions.

Future digital sheet metal factories will pay more attention to human-machine collaboration. Collaborative robots can work with workers to complete highly repetitive and dangerous tasks, such as welding and handling. Workers can work with robots to complete complex tasks and improve production efficiency and safety.

AI will play an important role in the future, providing workers with real-time decision support, such as helping to detect product quality through visual recognition systems, or guiding operators through voice interaction on how to quickly solve production problems.

As the circulation of materials and finished products increasingly relies on intelligent logistics, digital sheet metal factories will generally adopt automated handling equipment, unmanned vehicles, intelligent shelves and other systems to achieve intelligent scheduling and rapid delivery of materials and finished products.

With the help of RFID, Internet of Things and big data technology, sheet metal factories in the future will be able to achieve more accurate and efficient inventory management, avoiding inventory backlogs and material shortages.

Digital sheet metal factory will add digital management to the entire process of product design, manufacturing, use, maintenance, recycling, etc., to achieve data traceability and optimization of the entire life cycle of the product.

More and more sheet metal factories will not only provide product manufacturing services, but also provide a series of services such as later maintenance, upgrading, recycling, etc. to enhance customer stickiness and enhance the long-term competitiveness of enterprises.

The development trend of digital sheet metal factory is towards intelligence, automation, flexibility and sustainable development. Technological innovation and digital transformation will greatly improve the production efficiency, quality control and response speed of the sheet metal industry, enabling enterprises to occupy a favorable position in the fiercely competitive market. At the same time, these trends will also drive the entire manufacturing industry towards a greener, low-carbon and sustainable direction.