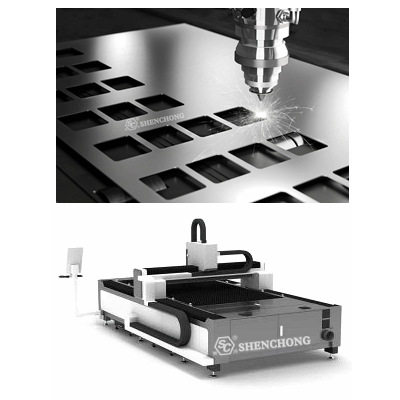

Laser cutting is a processing method that uses high power density laser as the heat source, and uses computer-aided design and computer-aided manufacturing technology to achieve surface melting, evaporation, or decomposition of the processed workpiece under the irradiation of the laser beam to form a cut according to the designed cutting trajectory.

Laser cutting is widely used in manufacturing fields such as automobiles, home appliances, and electronic products.

Laser cutting is achieved by irradiating the cutting area with a high-energy density laser beam, causing the surface of the material to evaporate or melt, while forming small slits on the surface of the material to achieve the cutting purpose.

Under the action of laser, strong physical and chemical changes occur on the surface of the material, causing the processed material to melt, evaporate, or decompose, resulting in the formation of notches.

Laser cutting belongs to non-contact machining and is a non-contact machining method that does not require tools or molds. There are two types of laser cutting machines: pulse and continuous, with high output power and fast speed. Continuous laser cutting machines can produce continuously.

Laser cutting can be divided into four categories: laser vaporization cutting, laser melting cutting, laser oxygen cutting, and laser scribing and controlled fracture.

Using a high-energy density laser beam to heat the workpiece, the temperature rises rapidly, reaching the boiling point of the material in a very short time, and the material begins to vaporize, forming vapor.

The ejection speed of these vapors is very high, and at the same time, they form notches on the material. The heat of vaporization of materials is generally high, so laser vaporization cutting requires a high power and power density.

Laser vaporization cutting is commonly used for cutting extremely thin metal materials and non-metallic materials such as paper, cloth, wood, plastic, and rubber

When laser melting and cutting, the metal material is melted by laser heating, and then non oxidizing gases (Ar, He, N, etc.) are sprayed through a nozzle coaxial with the beam, relying on the strong pressure of the gas to expel the liquid metal, forming a cut. Laser melting cutting does not require complete vaporization of metal, and the required energy is only 1/10 of vaporization cutting.

Laser melting cutting is mainly used for cutting materials or active metals that are not easily oxidized, such as stainless steel, titanium, aluminum, and their alloys.

The principle of laser oxygen cutting is similar to that of oxygen acetylene cutting. It uses laser as a preheating heat source and active gases such as oxygen as cutting gases. On the one hand, the gas blown out reacts with the cutting metal and undergoes an oxidation reaction, releasing a large amount of oxidation heat.

On the other hand, molten oxides and molten materials are blown out of the reaction zone, forming notches in the metal. Due to the large amount of heat generated by the oxidation reaction during the cutting process, the energy required for laser oxygen cutting is only half of that for melting cutting, and the cutting speed is much faster than that of laser vaporization cutting and melting cutting. Laser oxygen cutting is mainly used for easily oxidized metal materials such as carbon steel, titanium steel, and heat treated steel.

Laser scribing is the use of high-energy density laser to scan the surface of brittle materials, causing the material to evaporate into a small groove. Then, a certain pressure is applied, and the brittle material will crack along the small groove. The lasers used for laser scribing are generally Q-switch lasers and CO2 lasers.

Controlled fracture is the use of the steep temperature distribution generated during laser grooving to generate local thermal stress in brittle materials, causing the material to fracture along small grooves.

Compared with other thermal cutting methods, laser cutting has the overall characteristics of fast cutting speed and high quality. Specifically summarized as follows.

Due to the small laser spot, high energy density, and fast cutting speed, laser cutting can achieve good cutting quality.

- The laser cutting incision is narrow, with both sides of the cutting seam parallel and perpendicular to the surface, and the dimensional accuracy of the cutting part can reach ± 0.05mm.

- The cutting surface is smooth and beautiful, with a surface roughness of only a few tens of micrometers. Even laser cutting can be used as the final process without mechanical processing, and the components can be directly used.

- After laser cutting, the width of the heat affected zone of the material is very small, and the performance of the material near the cutting seam is almost unaffected. Moreover, the workpiece deformation is small, the cutting accuracy is high, the geometric shape of the cutting seam is good, and the cross-sectional shape of the cutting seam presents a relatively regular rectangular shape. The comparison of laser cutting, oxyacetylene cutting, and plasma cutting methods is shown in Table 1. The cutting material is 6.2mm thick low-carbon steel plate.

Due to the transmission characteristics of laser, laser cutting machines are generally equipped with multiple CNC workstations, and the entire cutting process can be fully CNC controlled.

When operating, simply changing the CNC program can be used to cut parts of different shapes, which can perform both two-dimensional and three-dimensional cutting.

Using a laser with a power of 1200W to cut 2mm thick low-carbon steel plates, the cutting speed can reach 600cm/min. Cut 5mm thick polypropylene resin board with a cutting speed of up to 1200cm/min.

The material does not need to be clamped and fixed during laser cutting, which not only saves tooling fixtures but also saves auxiliary time for loading and unloading.

During laser cutting, there is no contact between the cutting torch and the workpiece, and there is no tool wear. Processing parts of different shapes does not require changing the "tool", only changing the output parameters of the laser. The laser cutting process has low noise, low vibration, and no pollution.

Compared with oxyacetylene cutting and plasma cutting, there are many types of laser cutting materials, including metal, non-metal, metal based and non-metallic composite materials, leather, wood, and fibers.

However, for different materials, due to their own thermal physical properties and different laser absorption rates, they exhibit different laser cutting adaptability.

Due to limitations in laser power and equipment volume, laser cutting can only cut medium to small thickness plates and pipes. Moreover, as the thickness of the workpiece increases, the cutting speed significantly decreases.

In addition, laser cutting equipment is expensive and requires a large one-time investment.

Most laser cutting machines are controlled by CNC programs or made into cutting robots. Laser cutting, as a precision machining method, can cut almost all materials, including two-dimensional or three-dimensional cutting of thin metal plates.

Laser cutting is mainly used for metal plates, including stainless steel, carbon steel, aluminum, copper, titanium, and titanium alloys. Among the above-mentioned metal materials, stainless steel and carbon steel are currently widely used, among which the processing technology of stainless steel is a key aspect in the entire laser cutting industry.

With the advancement of technology and the improvement of market demand, laser cutting technology is developing towards smaller, thinner, and more precise directions. Currently, laser cutting has been widely applied in fields such as automotive manufacturing, home appliance manufacturing, and electronic component manufacturing, becoming one of the important means for the transformation and upgrading of domestic and foreign manufacturing industries.

In the field of automobile manufacturing, the cutting technology of spatial curves such as car roof windows has been widely applied. Volkswagen in Germany uses a laser with a power of 500W to cut complex shaped body sheets and various curved parts.

In the field of aerospace, laser cutting technology is mainly used for the cutting of special aviation materials, such as titanium alloys, aluminum alloys, nickel alloys, chromium alloys, stainless steel, beryllium oxide, composite materials, plastics, ceramics, and quartz.

Aerospace components processed by laser cutting include engine flame tubes, titanium alloy thin-walled casings, aircraft frames, titanium alloy skins, wing stringers, tail wall panels, helicopter main rotors, and ceramic insulation tiles for space shuttles.

- Due to the rapid development of laser processing technology and continuous improvement of laser cutting process, cutting quality is no longer a single goal of laser cutting. Improving production efficiency, reducing processing costs, and further improving and improving laser cutting process will become an important direction of its development.

- With the continuous progress of modern manufacturing technology, the functions of laser cutting machines are also constantly improving, and the supporting equipment is also constantly upgrading. People are paying more and more attention to laser cutting processing.

- With the continuous improvement of industrial production requirements, higher requirements have been put forward for the automation and intelligence level of laser cutting machines. Automatic control and intelligent technology will become a new direction for the development of laser cutting machines.

- With the increasing emphasis on green manufacturing and green technology, laser cutting machines are developing towards green and energy-saving directions.