A stainless steel grooving machine refers to a machine that manufactures machines, also known as a work machine or tool machine, commonly referred to as a machine tool. Generally divided into metal cutting machine tools, forging machine tools, and woodworking machine tools.

There are many methods for processing mechanical parts in modern mechanical manufacturing: in addition to cutting, there are also casting, forging, welding, stamping, extrusion, etc. For parts with high precision requirements and fine surface roughness requirements, they generally need to be processed using cutting methods on machine tools.

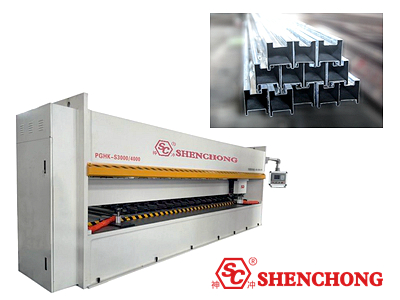

The steel cnc v grooving machine is suitable for industries that require highly processed boards, such as elevators, decorative materials, stainless steel processing, household appliances, and props display. Steel plate welding structure, annealing and aging treatment, good stability, high working accuracy, and very high processing efficiency, greatly reducing the labor intensity of workers.

The working principle of a cnc v grooving machine is to fix the board material that meets the grooving machine on the workpiece table, adjust the processing starting point (origin), and use the tool holder adjustment machine to drive the tool holder to plane and process the board, forming the required V-shaped groove. The depth and width of the V-shaped groove can be ensured by the feed amount and different cutting tools.

Processing of stainless steel grooving machine:

- V-groove machining is generally carried out when customers have special requirements for the bending of sheet metal parts, and normal bending cannot achieve the minimum required value. At this point, use grooving and bending.

- The structural size design of sheet metal parts is special, and when it cannot be reached through normal bending, grooves need to be planed. For example, for U-shaped structural parts, the inner cavity size is only a few millimeters, and in this case, double V-groove shaping is used.

- Depth, width, and angle of V-groove planing.

The grooving machine is divided into horizontal grooving machines and vertical grooving machines. Compared to other machines, vertical grooving machines have six advantages:

The method of directly correlating the groove depth to the bending angle. If the depth deviation reaches 0.05mm, the bending position is clearly inconsistent. During the operation of a vertical grooving machine, the blade should operate stably in a straight position from the cutting edge to the table surface, and the spacing between the blade tip and the table surface should be controlled within a limit of 0.02mm. When operating a horizontal grooving machine, it is difficult to operate within a range of 0.1mm with the accuracy of a 4000*1500mm platform.

When the vertical cnc v grooving machine is cutting, the tool holder partially moves back and forth, with a weight of about 60KG. When the horizontal stainless steel grooving machine is cutting, the tool holder and gantry machine tool part start to move back and forth together, with a weight of about 1000KG. Its energy consumption is more than ten times that of the vertical stainless steel grooving machine.

The vertical steel grooving machine has about ten types of separate pressing plates and ten types of separate clamps that can actively clamp the plate material. No matter how thin the plate is, it can be manufactured, and grooves can be made in both longitudinal and transverse directions. The horizontal v grooving machine is only used for slotting large plates. After the longitudinal slotting, the plate is squeezed and cannot be clamped horizontally, resulting in the inability to slot horizontally.

The working surface of the vertical groove machine is finely ground by a grinder, achieving a mirror like effect with exquisite appearance. The working table of the horizontal stainless steel grooving machine is made by riveting ordinary plates, and the stainless steel raw material is also harder than it, which is prone to wire breakage and blade damage, making the table uneven.

The vertical steel grooving machine is riveted from steel plates, with high hardness and stable and quiet operation. As long as the flat and sturdy cement ground is displayed and leveled, the operation can be consolidated. The horizontal stainless steel grooving machine has a large influence due to the gantry operation. In addition, the table should be basically adjusted, and the foundation needs to be made according to the installation diagram.

The vertical v grooving machine is forced to install parts by hydraulic right and wrong, self-locking and self-operating, and the operator can be far away from the operating position of the machine tool.