Electrical cabinet is a cabinet used to protect the normal operation of components. The electrical cabinet is also called distribution cabinet. The distribution cabinet is a cabinet body that integrates electrical components used for energy distribution.

Electrical cabinets are cabinets made of steel material to protect the normal operation of components. The materials used for making electrical cabinets are generally divided into two types: hot-rolled steel plate and cold-rolled steel plate. Cold-rolled steel plate is softer in material compared to hot-rolled steel plate, making it more suitable for the production of electrical cabinets.

It is widely used in the chemical industry, environmental protection industry, power system, metallurgical system, industry, nuclear power industry, fire safety monitoring, transportation industry, and so on.

Internal components include: busbar (busbar), circuit breaker, conventional relay, comprehensive relay protection device, measuring instrument, isolation switch, indicator light, grounding switch, etc.

One function is to distribute and control electrical equipment. The second function is to provide power supply protection in the event of overload, short circuit, and leakage in the circuit.

The common types of electrical cabinets include fixed panel electrical cabinet, protective electrical cabinet, drawer electrical cabinet and power lighting distribution cabinet.

Let's take a look at the characteristics of these types of distribution cabinets.

Fixed panel electrical cabinets are also known as distribution panels. Its front is a cabinet panel, which can be used for blocking and opening/closing. The back and sides are open and can come into contact with charged devices.

The fixed panel distribution cabinet has a low level of protection and can only be used in situations where safety requirements are not high and continuous power supply is required. For example, in industrial and mining enterprises, it is used for centralized power supply in substations.

Compared to fixed panel electrical cabinets, protective electrical cabinets have a true cabinet body. Except for the installation surface, all sides are sealed with baffles.

The cabinet body of the protective distribution cabinet is made of insulating materials. Internal electrical components are isolated from the outside. Components can also be isolated using protective plates. Therefore, the safety level of protective distribution cabinets is relatively high, and they can be applied to power distribution devices in process sites.

The drawer type pull-out distribution cabinet is one of the safest distribution equipment. It is made of steel plate for the cabinet body. Drawers are installed inside the cabinet. Each electrical component is installed in a drawer, forming an independent functional unit.

The reliability, interchangeability, and safety of drawer type electrical cabinets are higher than the above two types of distribution cabinets, making them suitable for centralized control distribution centers with high requirements for power supply reliability.

The power lighting distribution cabinet adopts enclosed installation. The safety level varies depending on the requirements of the usage occasion. Power lighting distribution cabinets are often used as low-level distribution equipment, such as for power distribution control in production sites of industrial and mining enterprises.

As a facility for controlling circuit wires, it has a small size and meets the requirements of various occasions, making it easy to install and use.

The distribution cabinet is used for power supply, transmission and other tasks, and must comply with standardized requirements to ensure safety.

The components and circuits of the distribution cabinet need to be isolated or sealed to effectively extend their service life and increase their economic value.

Electrical cabinets are widely used for power distribution control in residential buildings, schools, and hospitals due to their excellent functions. Distribution cabinets are often seen in enterprise factories and workshops, such as lighting distribution cabinets and power distribution boxes.

Generally speaking, distribution cabinets are mainly divided into primary, secondary, and tertiary distribution equipment. The distribution cabinet is suitable for different occasions, and when selecting and installing it, it is necessary to follow the standards. Only qualified products are a strong guarantee of safe production.

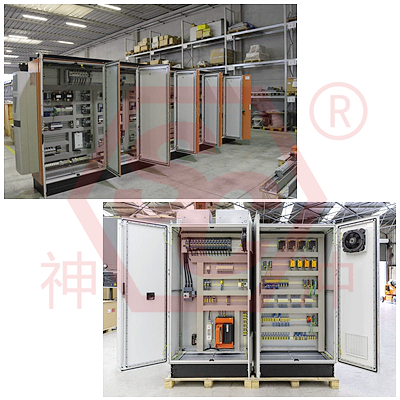

SHENCHONG cnc press brake for sale Electric Control Cabinet adopts Schneider (France) Components with high quality and stable performance to ensure the electrical components using time.

Electrical cabinet manufacturing refers to the use of a series of control technologies and electrical equipment in modern power, electronics, construction and other fields to produce control cabinets that meet user needs. They can achieve control, protection, coordination, and management functions in practical applications.

The equipment used in the manufacturing of electrical cabinets includes steel plates, components, control components, accessories, auxiliary components, processing equipment, etc. They are a complete electrical control system that can achieve automatic control and detection functions, improving the performance and safety of the electrical system. The bending machine of Shenchong can be used for the manufacturing and processing of electrical cabinets.

The manufacturing process of electrical control cabinets mainly includes design, production, installation, debugging, inspection, etc. Design is an important part of it. Manufacturers should design reasonable structures based on different application needs and customer requirements to ensure that the control cabinet meets safety and reliability requirements.

The production process includes material cabinet bending, welding, control component installation, cable laying, assembly, etc. Equipment operators are required to master the correct operating methods to ensure quality.

The installation process requires the installation engineer to complete the installation according to the design requirements, ensuring that the installation structure of the electrical cabinet is firm and reliable.

The debugging process involves installing the control cabinet into the electrical system. Conduct debugging according to design requirements to ensure the normal use of the control cabinet.

The inspection process requires inspectors to conduct multiple actual inspections of the control cabinet in accordance with design requirements and relevant national standards to ensure the quality of the control cabinet.

Electrical cabinet manufacturing is an industry with high technical requirements, which requires strict compliance with regulations from design to production, installation, debugging, inspection, and other steps to ensure the quality of control cabinets.

High Precision Shearing Machine For Sale

Manufacturers producing electrical cabinets need to purchase high-precision and high-quality processing equipment for production work. Even some manufacturers have started to choose automated production lines for production. This is also a major trend in the manufacturing industry.