DELEM DAC 360 CNC Shearing Machine Controller Compact and versatile system for advanced shears. With bright LCD screen, operation is most user-friendly. The numerical programming with clear icons guides the operator through all programming functionalities.

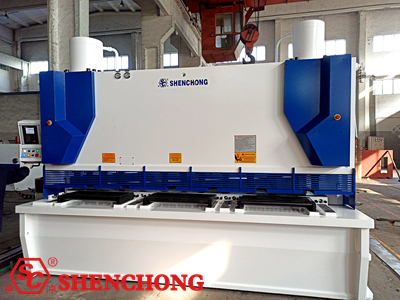

Wuxi Shenchong uses DAC360 system in cnc hydraulic guillotine shears. Also, we have ELGO P40 controller for optional. You can choose according to your requirements.

Now, Shenchong shearing machine manufacturer give you detailed information about DELEM DAC 360 controller to reference.

The CNC shear DAC-360 control provides a user-friendly and versatile control solution for shears. Upon demand multiple back gauge axes, cutting angle, stroke length and gap can be controlled, based on state-of-the-art electronics. Next to back gauge control, the DAC-360T automatically calculates the required setting for the cutting angle and gap depending on material properties and thickness. The stroke length is optimized based on the required cutting length, thus increasing productivity.

The back gauge control supports servo control, 2-speed AC control as well as inverter control. Depending on the application you can select either two-side positioning or single side positioning, using optional spindle correction functionality.

Full force control for clamping and cutting is available in the DAC 360 CNC shearing machine controller. With bright LCD screen, operation is most user-friendly. The numerical programming with clear icons guides the operator through all programming functionalities.

The DAC-360 series provides compact shear control solutions for a variety of functionality on modern shears.

- Panel based housing

- 4.7” bright LCD screen display

- Back / front gauge control

- Retract function

- Cutting angle and gap control

- Digital variable speed output terminal

- Analog output terminal

- Stroke length limitation

- Manual movement of all axes

- Force control

- Sheet thickness measurement

- Material table for cutting angles and blade gaps in the computer system

- Return to Sender function

- Sheet support

You can directly input the parameters of the cut sheet material. And the system controls automatic positioning of the two axes.

The DAC360 CNC shearing machine system can store 25 processing steps. Program memory can control 1000 program sentences. Call the stored processing operations as needed and automatically execute them. Easy to operate.The positioning speed of the three-axis CNC motor can be adjusted arbitrarily, thereby improving work efficiency. Internal parameter adjustment function. You can freely modify the reference points of the two axes to adjust the positioning value of the CNC system.

The system has an automatic concession function. It can make the feeding frame move away in a timely manner during the cutting process. Avoid friction between the blade and the plate during the cutting process.

Every time the machine is powered on or off and restarted, the two axes controlled by the CNC system can automatically find reference points to ensure repeated positioning accuracy.

Standard | |

Display | LCD display |

Type | 7" widescreen TFT, high brightness |

Backlight | LED |

Resolution | 1024 x 600 pixels, 32 bit colour |

Storage capacity | Program memory for 100 programs |

Program steps | 25 steps per program |

Housing | Panel version |

Exchangeable memory | USB flash memory drive |

Options | |

Version | DAC-360T, compact touch shear control |

Expanded version | DAC-362T, multi axes compact touch shear control |

Offline Software | Profile-360T / Profile-362T |

- Program library

- Millimetres / inches selection

- Power-down memorisation

- Machine hour counter

- Stroke counter

- Back/front gauge control

- Stroke control

- Gap control (dual gap)

- Angle control

- Dual / triple gauge control (DAC-362T)

- Stroke 0 - 9,999.99 mm

- Retract 0 - 9,999.99 mm

- Correction -99.99 - 99.99 mm

- Retract programmable

- Simultaneous axes movement

- Manual movement of axes

- Flexible I/O configuration

- 12 inputs / 20 outputs

- Numerical program setup

- Back gauge position

- Retract function

- Angle programming

- Gap programming

- Stroke length

- Step repetition

- Material types / properties

- Thickness

- Stock counter

- Sheet position

- Axis speed

- Sheet support

- Return to Sender function

- Sheet thickness measurement

- Back gauge park position

- Angle, gap and stroke length computation

- Force (clamping / cutting)

- Backgauge safety zone

- Clamping force

- Diagnostic mode

- Service mode

- Backup and updates via USB

- Power supply: 24V

- Opto-isolated digital I/O

- Encoder inputs (5V/12V)

- Max. encoder frequency 1 MHz

- USB port

- +/- 10V for servo control

- 1-or 2-speed control for AC motors

- Frequency inverter control

- Panel based housing

- Dimensions 186 x 252 x 45 mm

- Operator selectable dialogue languages

- Optional offline software

Powerful as a tool can be, operating plate shearing machines is made even easier, cuttting both material and cost.

Confidence for operators increasing productivity. Finding functions easily, offering cutting at its best.

Strong and sturdy as the shear machine it is controlling, reliable solutions. Control and machine are one.

New technologies enabling highest accuracies, enhancing functions and user friendliness at a whole new level.

Click here to know other shear machine controller: