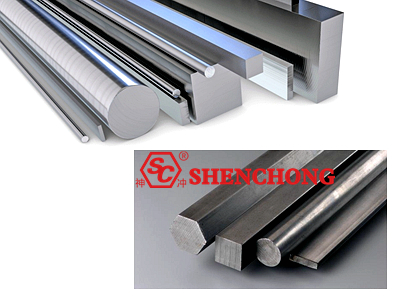

Alloy steel refers to the addition of other alloying elements in addition to iron and carbon to steel, which is called alloy steel. Metal elements can be added. It can also be non-metallic elements, such as Si, Mn, Cr, Ni, Mo, W, V, Ti, Nb, Zr, Co, Al, Cu, B, and rare earth elements.

Among them, V, Ti, Nb, Zr, etc. are strong carbide forming elements in steel. As long as there is enough carbon, their respective carbides can be formed under appropriate conditions. When carbon is deficient or at high temperature, it enters solid solution in atomic state.

Mn, Cr, W, Mo, etc. are elements that form carbides. Some of them enter solid solution in atomic state. The other part forms a displacement type alloy cementite. Al, Cu, Ni, Co, Si, and other elements do not form carbides. Generally, it exists in solid solution in atomic state.

Alloy elements have a significant impact on the microstructure and properties of steel. Its main function is to strengthen ferrite, form alloy carbides, refine grains, and improve the hardenability and tempering stability of steel.

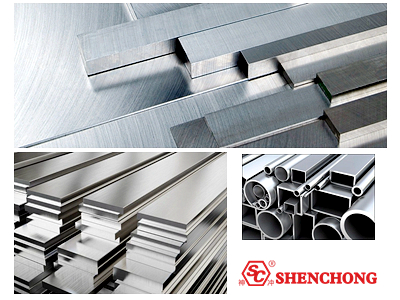

- Alloy structural steel: steel used for manufacturing mechanical parts and engineering structures.

- Alloy tool steel: steel used to manufacture various tools.

- Special performance steel: steel with certain special physical and chemical properties.

- Low alloy steel: total alloy element content less than 5%

- (Medium) Alloy steel: total content of alloy elements is 5-10%

- High alloy steel: total content of alloying elements is greater than 10%.

Alloy steel is mainly used in situations requiring wear resistance, corrosion resistance, high temperature resistance, low temperature resistance, and non magnetic properties.

Low alloy structural steel refers to engineering steel with a small amount of alloying elements added to carbon structural steel.

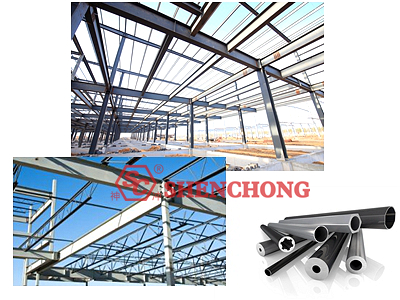

It includes low alloy high-strength structural steel, such as 09MnV, 18Nb, 12MnSiCu, etc. This type of steel has much higher strength than carbon structural steel with the same carbon content. It has good plasticity, toughness, corrosion resistance, weldability, etc. It is widely used to manufacture steel structural parts such as bridges, ships, vehicles, boilers, pressure vessels, hoisting machinery, etc.

Generally, the plate bending machine can be used to process ships, large boilers, pressure vessels. Due to the diverse types of alloy steel with varying tensile strength, it is necessary to communicate with the manufacturer to calculate the machine model when purchasing a bending or rolling machine.

Low alloy corrosion-resistant steel has good weldability and atmospheric corrosion resistance, and is suitable for bridges, buildings, and other structural components with corrosion resistance requirements. For example, 10MoVNiTi, 40MnMoNb, Cr4AlMo, etc.

Low alloy professional steel has professional applications. The chemical composition of various types of steel can be adjusted accordingly according to the requirements of its performance. For example, low alloy steel reinforcement (20MnSi), railway low alloy steel (09CuPRE), mining low alloy steel (20MnVK), etc.

After carburizing and quenching, alloy carburized steel undergoes low-temperature tempering to achieve high hardness and wear resistance on the surface of the parts. And its interior has sufficient plasticity and toughness.

Mainly used to manufacture parts that have excellent wear and fatigue resistance, as well as the ability to withstand impact loads. For example, 20CrMoTi, 20CrNi4, 20Cr, etc.

Alloy steel has comprehensive mechanical properties after quenching and tempering (high-temperature tempering after quenching). It has both high strength and good plasticity and toughness. Mainly used to manufacture important parts with complex stress, such as 40Cr, 35CrMo, 38CrMoAl, etc.

Alloy spring steel has high strength and fatigue limit, as well as sufficient plasticity and toughness. Mainly used to manufacture elastic parts in various machines and instruments. These parts utilize elastic deformation to absorb energy to slow down vibration and impact, or rely on elastic energy storage for driving purposes, such as 60Si2Mn.

Rolling bearing steel has high hardness and wear resistance, high elastic limit and high contact fatigue strength, sufficient plasticity, and certain corrosion resistance. Mainly used to manufacture inner and outer rings and rolling elements of various bearings, as well as various tools and wear-resistant parts, such as GCr15.

Alloy tool steel mainly includes alloy cutting tool steel, alloy mold steel, and alloy measuring tool steel.

It is a steel with a small amount of alloy elements added on top of carbon tool steel. For example:

9SiCr:

It has high hardenability and tempering stability, and the carbides are fine and uniform. The thermal stability can reach 300 ℃. Suitable for making low-speed cutting tools with thin cutting edges.

CrWMn:

It has high hardness and wear resistance, and small deformation after heat treatment. Mainly used to manufacture precision low-speed cutting tools.

W18Cr4V (high-speed steel):

It has high thermal hardness, high wear resistance, and sufficient strength. The thermal hardness can reach 600 ℃. Can maintain long-term sharp edge during cutting. Commonly used for manufacturing cutting tools with high cutting speeds and forming tools with complex shapes and high loads, it can also be used for manufacturing cold extrusion molds and certain wear-resistant parts.

Alloy mold steel mainly includes cold work mold steel and hot work mold steel.

Cold working mold steel has high hardness, wear resistance, certain toughness, and fatigue resistance, and is mainly used to manufacture molds for metal deformation in the cold state. In work, it has to withstand significant pressure, bending force, impact load, and friction, such as NAK55.

Hot work mold steel has high thermal strength and hardness. High temperature wear resistance and high oxidation resistance. High thermal fatigue resistance and thermal conductivity. Mainly used to manufacture molds that shape metals at high temperatures, such as HDM5.

Alloy measuring tool steel generally requires high hardness, high wear resistance, high dimensional stability, and sufficient toughness. There is no specific steel grade for manufacturing measuring tools, usually made of carbon tool steel, rolling bearing steel, and alloy tool steel, such as T10A, 60Mn, 40Cr13, etc.

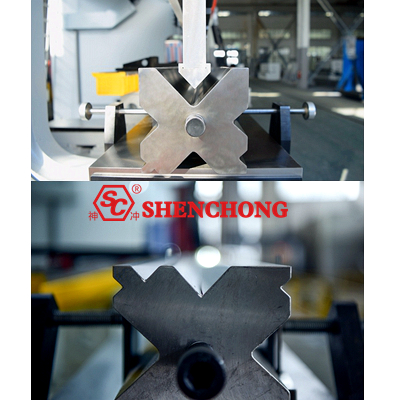

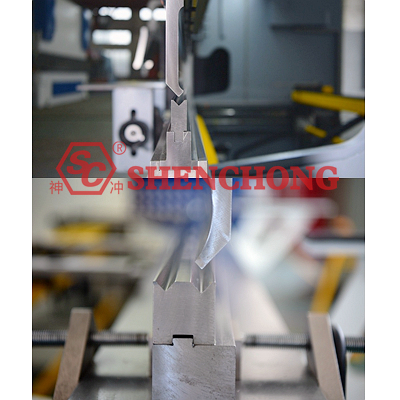

T8 is the material of the ordinary press brake tooling (square die), HRC44 ± 2 °. 42CrMo is a CNC bending tool (single V die, double V die) with HRC47 ± 3 °.

Stainless steel is a type of steel with good corrosion resistance used in atmospheric and corrosive media.

Chromium stainless steel:

Chromium stainless steel often refers to Cr13 type stainless steel. It has good resistance to atmospheric, seawater, steam and other media corrosion, and has good plasticity and toughness. Suitable for manufacturing steel that works under weakly corrosive conditions and requires a certain strength.

Chromium nickel stainless steel:

After heat treatment, chromium nickel stainless steel exhibits single-phase austenite structure, with better corrosion resistance, plasticity, and toughness than chromium stainless steel. It is mainly used for manufacturing parts that work in highly corrosive media, such as Cr18Ni9.

Heat-resistant steel is a type of steel that exhibits high oxidation resistance and strength at high temperatures. Antioxidant steel is a steel that has good oxidation resistance at high temperatures and has a certain strength. Mainly used for manufacturing parts that work under high temperatures for a long time but have low strength requirements, such as 1Cr6Si2Mo.

Hot-strength steel is a steel that has good oxidation resistance and high high-temperature strength at high temperatures. Used for manufacturing parts that work at high temperatures and withstand impact loads, such as 14Cr1MoR, 12Cr2MnR, etc.

Wear resistant steel has good toughness and wear resistance, mainly used for manufacturing parts that withstand severe friction and strong impact, such as ZGMn13.

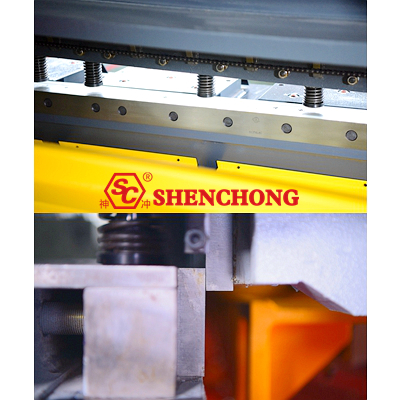

6CrW2Si is a material used for ordinary shearing machine blades, HRC53 ± 2 °, for cutting mild steel. When customers have higher requirements for cutting stainless steel plates, the blade material needs to be Cr12MoV, HRC58 ± 2 °.