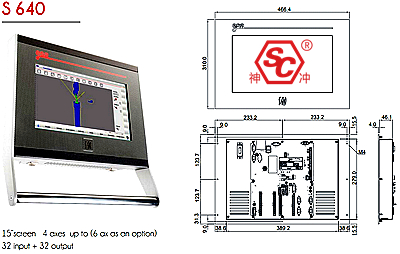

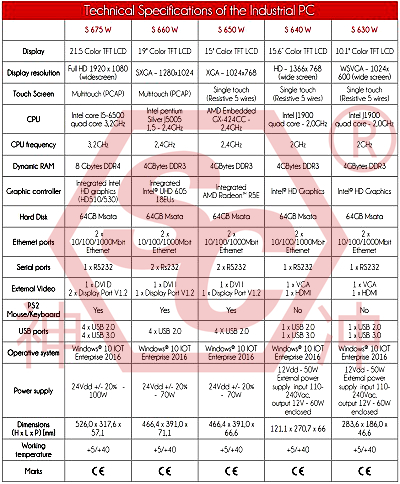

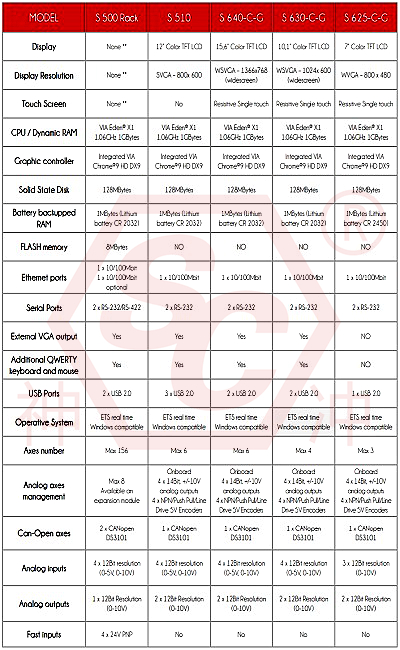

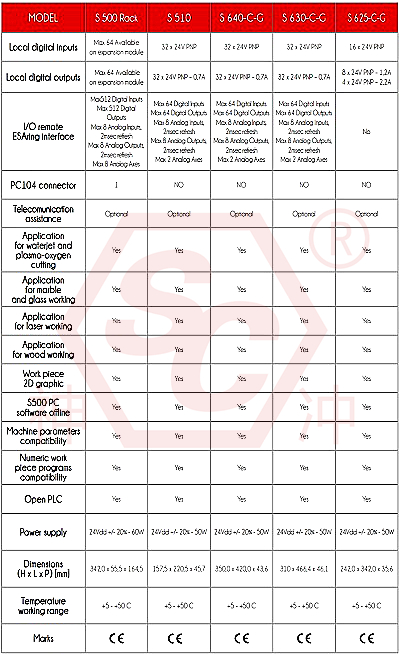

ESA S640 CNC Press Brake Controller Maximum performance and maximum compactness in the splendor of a 15” LCD HD Touch screen. Up to 6 axes. The complete CNC line with touch screen and bundled software to control machines from the simplest to the custom ones, up to the incredible limit of 128 axes.

There are many CNC systems for bending machines, including DELEM, ESA, ELGO, Cybelec, and so on. Based on years of experience in manufacturing and maintaining CNC bending machines, Wuxi Shenchong, a professional press brake and shearing machine manufacturer, highly recommends users to choose the ESA S640 CNC system as the bending controller.

Now let's introduce this cnc press brake controller to everyone.

The new Esautomation CNC range is designed to meet demands for an increasing number of users for a performance-oriented, user-friendly CNC with up-to-the-minute functions and styling.

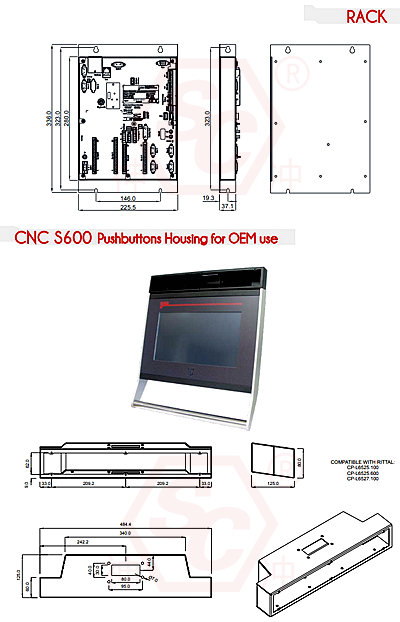

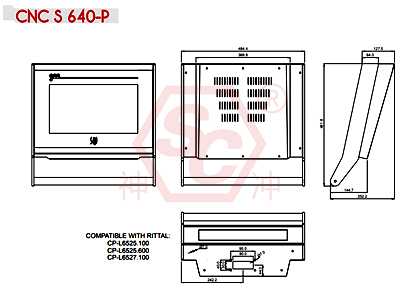

This led to the creation of a new range of products for bending applications combining the exceptional performance provided by the previous S500 line with a re-vamped and upgraded graphical environment, plus exclusive use of Touch Screen and Multitouch screens. Depending on the model, the new Esa S600 CNC line can handle the most simple machines multitandem robotic lines with up to 125 axes.

Maximum performance and maximum compactness in the splendor of a 15” LCD HD Touch screen. Up to 6 axes. Absolute performance in a full applications CNC for machines up to 6 axes. Large ultrasharp Tft LCD 15” color screen for a better user experience, thanks to the complete and intuitive HMI.

- All-in-one Monoboard

- Resistive 15” Tft LCD HD Touch color screen

- For all applications up to 6 axes

- Ergonomic and easy to use HMI

- 32 + 32 I / O with integrated PLC

- 1 Ethernet port + 1 optional

- 2 RS-232 serial ports

- 2 USB 2.0 ports

- 4 analog inputs + 2 analog outputs

- 1 CANopen port

- Available in 25 languages

A single CNC for all applications. An Esautomotion exclusivity. By seamlessly integrating with the turn-key software developed by Esautomotion, VIS-640 CNC hardware is suitable for all applications, such as: sheet metal bending, cutting, wood processing, marble processing and so on.

To exploit all the performances of ESA S640 CNC press brake controller, use them in combination with the other ESAUTOMOTION components.

The new Esautomation CNC range is designed to meet demands for an increasing number of users for a performance-oriented, user-friendly CNC with up-to-the-minute functions and styling.

This led to the creation of a new range of products for bending applications combining the exceptional performance provided by the previous S500 line with a re-vamped and upgraded graphical environment, plus exclusive use of Touch Screen and Multitouch screens. Depending on the model, the new Esa S600 CNC line can handle the most simple machines multitandem robotic lines with up to 125 axes.

Cnc plate shearing machines, Conventional press brakes, Synchro single-cylinder and twin-cylinder press-brakes, Hammerle press-brakes, Electrohydraulic (hybrid press brake) and Electrical press-brakes, Plate bending rolls, Profile bending machines......

The use of a can bus line for exchanging data between one CNC andanother, which allows tandem and multi tandem press-brakes (up to 4 machines in line) to be 1 without complex I/O 1 nterfaced 2 cabling and without requiring any synchronizing device.

Each CNC “sees” the optical scales of the other machines so as to perfectly synchronize the rams in every processing phase.

3)Remote support for the entire range:

The remote diagnostics service is available for the entire range of ESA S600 CNC press brake controller. It allows the manufacturer to determine the cause of faults in the machine installed change the cnc settings to restore optimum operation.

”Run time” and the deformation to which the machine is subjected when bending, are detected by strain gauges or potentiometers or others sensors Deformation is immediately compensated by means of CNC-controlled hydraulic cylinders. Thus, the resulting bend is always perfectly linear.

ESA S640 cnc press brake controller Esa CNC interface has the most sophisticated bending angle sensors. Our CNC can in real time detect bending errors, but also (if the machine allows) corrects the bend without the workpiece having to be removed from the machine.

Springback of material can also be compensated. Our CNC equipped with Personal Computers can host Data M governance software for optimizing cycle times and costs if this type of sensors are used.

6)Plc programmable by manufacturers:

All our CNC are equipped with an Open Plc to allow manufacturers develop special machine functions on their own. Languages available: IEC 61131-3 or “C”

Draw the workpiece profile using the simple “touch design” cad and leave the CNC to find the best bending solution and check for collisions… Choose one of the solutions proposed and start bending… Bending angle correction database

Deviation from the programmed angle is acquired by the machine as each bend is made, by type of material and its dimensions. This value is stored for future uses, for the purpose of improving precision and reducing waste.

Usb or wifi/bluetooth keyboards, Wila LED bar or similar to indicate the workstation to be fixtured and/or use for bending, usb or wifi electronic protractor remoting of operator interface on Tablet.

There’s a PC application that allows you to program and graphically check your work while sitting comfortably in your office. Once you’ve completed the program, it can be transferred to the machine’s CNC via usb or ethernet.

The 600 series supports the most widespread safety plc. Data are exchanged via serial line or ethernet.

Sensors located on the machine allow the CNC to measure the thickness of the metal plate and to automatically correct the bend.

Thanks to a powerful database and advanced interpolation algorithms, you can program a shape and obtain a suitable result with the least waste in terms of material. User-friendly programming of the most widespread shapes. Profile database are available for profile bending machines.

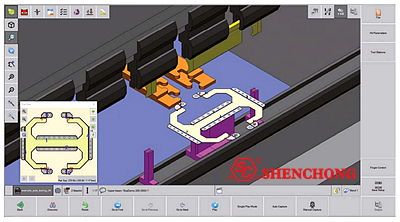

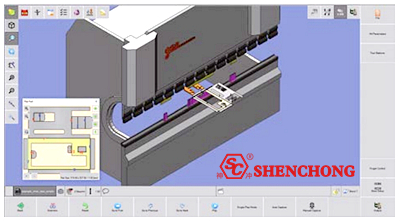

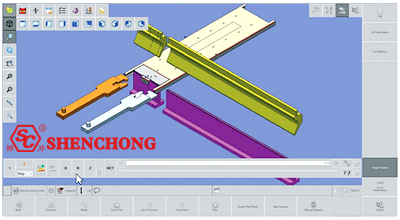

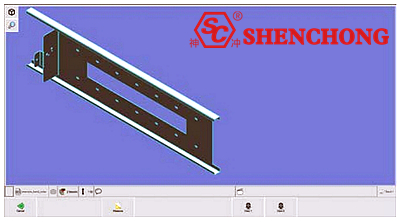

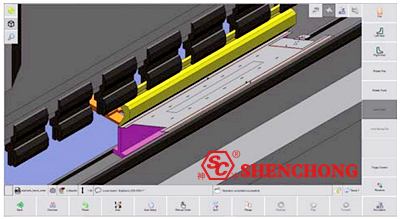

EsaBend is an application for the programming and the simulation of a Press Brakes with a CNC, used to increase productivity, decrease downtime and reduce material wastage.

EsaBend allows offline calculate the tooling and bending sequence, through a 3D simulation environment where they are checked for collision between the part, tools feedback and machine components.

- Direct import from SolidWorks, Solid Edge e Inventor

- Import and unfolds IGES and STEP 3D parts

- Automatic and manual tool selection based on the type of material, machine and tools properties

- Automatic and manual bending sequence with collision control

- Automatic calculation of the back gauges backing

- Automatic and manual back gauge positioning with interactive graphic controll of all axes

- 3D simulation of the bending process with collision detection

- Detailed report of tooling stations of the machine which also includes the bending sequence, the tools used and the graphic and specific information bend by bend

- Automatic features that speed up management time from design to finished product

- Offline programming which allows minimizing downtime

- Collision control in the bending sequence that allows a reduction of the material discarded

- Automatic and manual bending sequence with collision control

- The tools library is compatible with the availability of tools needed for the production

Based on:

- Availability of different types of tools and its fractionation

- Bend radius

- Maximum machine force

- Collisions control

- Definition of default tools crushed fold, for automatic recognition

- Setting the pre-bending angle, with default and editable value

EsaBend automatically calculates the sequence of bend taking into consideration the following points:

- Avoid collisions

- Availability of the fractionation of the tools

- Utensili a scarpetta per la gestione delle contropieghe interne

Full manual control:

- Split of complete folds into partial folds, with the angle definition of pre-fold

- Interactive editing of the order of the bending sequence

EsaBend provides automatic and manual control options of the back gauge:

- Automatic position press brake back gauge supporting

- Automatic calculation tooling considering the shape of fold

- Graphic and interactive control for all of the axis

- Snap Management on all axes for precise positioning stop

ESA S640 cnc press brake controller EsaBend comes with real-time, automatic 3D simulation, presenting a realistic visualization of the bending process. The simulation helps you to create an error-free process, producing NC code or a bending report. The simulation lets you check whether the part collides with the press brake, tool setups, finger-stops, or even with itself. It also checks whether the finger-stops collide with any of the tool setups, and whether the punches collide with the dies.

- Real-time animation

- Realistic visualization of bending process

- Dynamic collision analysis (e.g. backgauge movement)

- Detection of collisions between all moving elements

- Operator part handling

- 100% correct program

The complete tooling report includes:

- Bend sequence instructions

- Tool information and tool setup details

- Flat view with the bend sequence

- Product handling

- Bend By bend graphics

Complex and changeable bending processing requires CNC press brake machines with more axes. The more shafts the bender controls and the more comprehensive its functions, the higher the controller that needs to be matched. As an upgraded version, the ESA S640 controller has more complete functions and is more suitable for multi axis CNC press brakes.

If you want to know more about How to Choose CNC Press Brake Axis? Click!