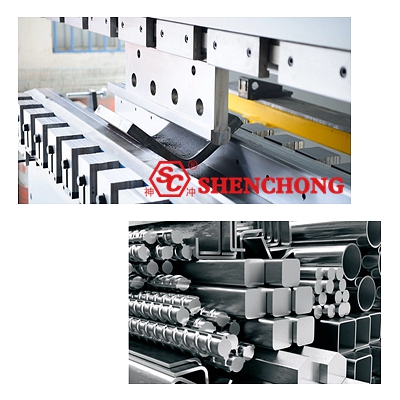

The application range of steel alloy in daily life is quite extensive now, and most of the products processed by customers using bending and shearing machines are steel alloys.

Next, we will analyze the advantages, disadvantages, and characteristics of common alloy steels.

Alloy steel has higher strength and toughness than carbon steel. Moreover, its strengthening effect tends to become apparent as the degree of organizational imbalance increases.

The strength of annealed steel alloy is not significantly superior to that of carbon steel. In the normalized state, the strength of steel alloy significantly increases compared to carbon steel, and after quenching and tempering, the strengthening effect is the most significant.

The hardenability mainly depends on its carbon content. Compared with carbon steel with the same carbon content, there is a slight increase.

However, their hardenability and tempering stability are significantly improved. Therefore, steel alloy is suitable for manufacturing steel parts in stainless steel engineering that have large cross-sectional dimensions, require thicker quenched layers, or require higher strength, hardness, plasticity, and toughness.

Moreover, when it is quenched, the cooling rate can be slower than carbon steel, making it less prone to deformation and cracking. This is particularly advantageous for parts with complex shapes or requiring minimal deformation.

Some steel alloys also have excellent thermal hardness and other special properties, such as heat resistance, corrosion resistance, wear resistance, and magnetism.

When using steel alloys, when its alloying element content is below 3%, it needs to be processed in order to achieve its process performance.

Due to the difficulty of welding, it will have a certain impact on the manufacturing cost. Its adhesion is difficult to control, so it must undergo certain welding treatment before it can be used normally.

Click here to know: Alloy Steel Classification: Common Types and Characteristics

It mainly contains chromium and manganese. The chromium content should be between 0.7% -1.2%. The content of manganese is 1.5% -2.5%.

It has good strength, plasticity, and wear resistance. It can also resist corrosion, but it is prone to overheating.

It mainly contains chromium, nickel, and carbon. The content of chromium is usually 11% -21%. The nickel content is 2% -4%.

They can resist the corrosive effects of air and water, and are less prone to rusting. Stainless steel has excellent wear and corrosion resistance. Therefore, it is widely used in kitchenware, textile, chemical, and shipbuilding industries.

However, due to the trace amounts of vanadium and chromium, its welding workability is relatively slow.

Carbon alloy steel refers to alloy steel with a carbon content between 0.4% and 2.0%. It has good strength and plasticity, and can be used for manufacturing parts such as bearings, bolts, shafts, etc.

The advantages are high strength, high ductility, good plasticity, good wear resistance, and low price. The disadvantage is easy rusting and poor corrosion resistance.

High strength alloy steel refers to alloy steel with a carbon content between 0.3% and 0.7%. It has the characteristics of high strength, high plasticity, and high wear resistance. It can be used to manufacture parts such as bearings, gears, bolts, shafts, etc.

The advantages are high strength, high ductility, good plasticity, good wear resistance, and low price. The disadvantage is poor corrosion resistance.

Heat resistant alloy steel refers to alloy steel with a carbon content between 0.2% and 1.0%, which has good heat resistance and corrosion resistance. It can be used to manufacture parts such as boilers, pipelines, heat exchangers, etc.

The advantages are good heat resistance, good corrosion resistance, high ductility, and good plasticity. The disadvantage is that the price is relatively high.

Meaning of alloy steel grade

The grade of alloy structural steel is represented by a two digit carbon content (mass fraction) + element symbol + number.

The first two digits represent the average carbon content of steel in tens of thousands of fractions. The element symbol indicates the main alloying elements contained in steel. The following numbers represent the percentage content of the element.

The grade of alloy tool steel is similar to that of alloy structural steel. The difference is that it uses a single digit to represent the thousandth of the average carbon content. But when its average carbon content is greater than 1%, the carbon content is not indicated.

The representation method of alloy elements is the same as that of alloy structural steel. The designation of special performance steel is the same as that of alloy tool steel.