We have introduced CNC bending machines before. CNC bending machine is a type of forging machinery, mainly used for metal processing. It is widely used in light industry, aviation, shipbuilding, metallurgy, instrumentation, electrical appliances, stainless steel products, steel structure construction, and decoration industries. CNC bending machine is currently the preferred machinery for sheet metal processing of sheet metal, especially large sheet metal. By selecting various molds, it can bend, stretch, round, punch, and so on.

But with the rapid development of the manufacturing industry, the process requirements for sheet metal bending are becoming higher and higher. Manually operating a CNC bending machine for bending cannot guarantee the consistency of the workpiece, resulting in different errors for each workpiece and failing to meet the standards.

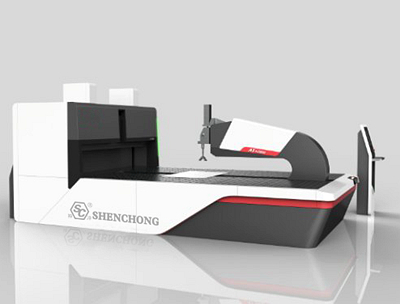

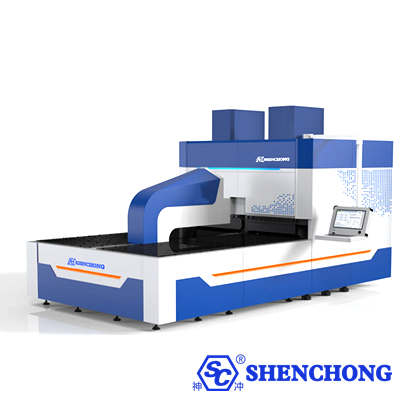

Today, we will introduce a more intelligent bending equipment: a flexible bending center. The flexible bending center is a new generation of fully automatic multilateral bending centers, which is a new product for sheet metal bending to enter fully automated production.

The flexible bending center working does not require a mold, and can bend various complex shapes such as right angles, non right angles, arcs, up and down folding, and complete multilateral bending in one positioning. It is applied in the metal forming field of different industries and workpieces.

The flexible bending center is composed of a control system, operating system, reducer, servo drive, screw, guide rail, bearing, negative pressure pump, machine frame, feeding frame, upper and lower bending blades, hinge knives, pneumatic accessories, suction cups, couplings, oil circuits, and so on.

- The flexible bending center adopts Industry 4.0 architecture, which can be smoothly upgraded, with fast speed, high consistency of workpiece forming, low power consumption, simple daily maintenance, and low cost.

- The flexible bending center is not limited by the column spacing and throat depth of the C-shaped structural frame design, and can fully utilize the bending machine for processing, making it more flexible and convenient. Moreover, its servo design allows for quick start and stop of machinery, fast processing speed, and can shorten processing time.

- The flexible bending center can automatically bend the four sides of the board in sequence, achieving automation. The universal bending mold can achieve double-sided bending of sheet metal. Using a CNC positioning device for automatic positioning, completing multilateral bending in one positioning.

- The intelligent flexible bending center has rich software and hardware interfaces, which can be selected based on the specific needs of conventional robotic arms on the market, and can be selected according to the actual needs of the demand side. The control system has achieved true nine axis (11 axis) concurrent linkage, smooth bending action, and high mechanical operation coordination.

- The intelligent flexible bending center adopts an off load inspection system, off load follow-up system, and thick plate detection system, which can effectively protect the machine, protect the workpiece, and reduce workpiece waste.

- For workpieces with non-standard dimensions, the flexible bending center can choose different positioning benchmarks based on the shape of the workpiece, controlling the bending error of the sheet metal on the first bending edge to ensure dimensional accuracy after forming. Rapid molding, high consistency, and low power consumption.

- The main body of the flexible bending center adopts a hybrid drive system and an efficient bending machine that can be configured for step-by-step bending. It is equipped with three-dimensional programming, offline control, automatic operation of the robotic arm, integrated servo pump system, high-speed rear stopper matching high-speed hydraulic system, resulting in higher overall efficiency.

- The flexible bending center adopts a cloud based operation and maintenance management system to monitor the machine's operation in real-time.

Compared to CNC bending machines, flexible bending centers have the following advantages

The advantage of a flexible bending center is its fast bending speed. Due to the manual adjustment of direction and bending required by the CNC bending machine, a large amount of manual labor is wasted. The bending speed of the flexible bending center is three times that of the CNC bending machine, greatly reducing the cycle time of multilateral and multi-channel bending, reaching 0.5/s per time. Full servo control can control the product accuracy within 3S, greatly saving labor.

The flexible bending center adopts a universal bending mold and achieves various shapes of bending through multi axis concurrent linkage full servo control. However, the traditional CNC bending machine needs the first mock examination for each bending shape, and the cost is high.

The flexible bending center reserves rich interfaces for convenient docking with the upstream and downstream production lines of sheet metal. It can connect with conventional robotic arms on the market, and the specific selection can be selected according to the actual needs of the user; Compatible with various loading and unloading methods: manual loading and unloading, truss robot loading and unloading, mechanical arm loading and unloading, etc., achieving full automation.

The CNC bending machine requires manual feeding of bent parts into the bending machine for bending, which poses certain safety risks. The flexible bending center automatically pushes the workpiece into the flexible bending center through the suction cup, and after the bending is completed, it is automatically pushed back through the suction cup. The entire process reduces manual intervention, and the safety performance of the flexible bending center is higher.

For workpieces with non-standard dimensions, different positioning benchmarks can be selected based on the shape of the workpiece to control the bending error of the sheet metal on the first bending edge, ensuring the accuracy of the formed dimensions and good control of the quality of the workpiece.

The control system achieves true 9-axis/13 axis (15 axis) concurrent linkage, smooth bending action, and high mechanical operation coordination; Friendly human-machine interface, simple and easy to understand, and flexible programming; High degree of automation, simple operation, and low technical requirements for operators.

Suitable for a wide range of materials, mainly including stainless steel, carbon steel plate, copper plate, aluminum plate, etc.

The flexible bending center has a bias load detection system, a bias load follow-up system, and a thick plate detection system, which can effectively protect the machine, protect the workpiece, and reduce workpiece waste.

With the development of the times, the flexibility of the performance of CNC bending machines is also a trend. In order to match the production process with a wider range of applications and stronger reliability, the development of flexible production technology will definitely take it to a higher level. Flexible bending centers have been widely used in various industries such as kitchenware, ventilation, air conditioning, filing cabinets, electrical cabinets, tool cabinets, and environmental purification. For the bending processing of metal sheets, more and more people are choosing flexible bending centers.