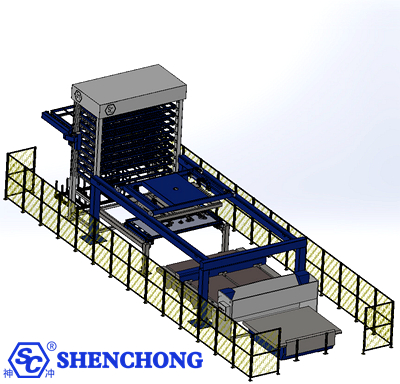

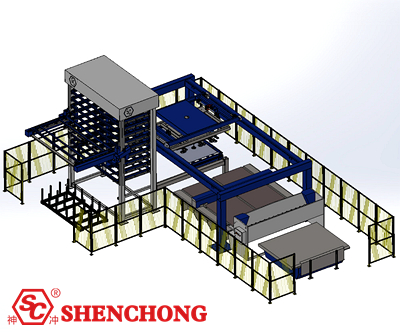

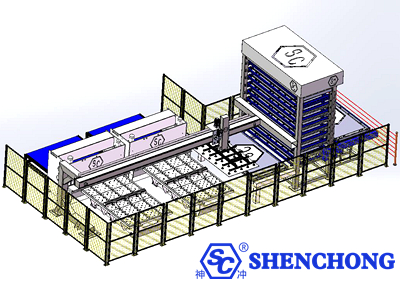

The automatic non-ferrous metal shearing production line is an automated system for efficient and precise shearing of non-ferrous metal materials such as aluminum, copper, and titanium.

The production line integrates multiple links such as feeding, leveling, shearing, conveying, and stacking. It is highly automated and intelligent and is widely used in aerospace, automobile manufacturing, electronics, construction and other industries.

Nonferrous metal materials are a type of metal material, mainly copper, cobalt, aluminum, lead, nickel, and titanium. Its corrosion resistance depends largely on its purity. After adding other metals, its mechanical properties are generally improved, but its corrosion resistance is reduced. Cold processing (such as stamping) can increase its strength, but reduce its plasticity.

Copper (and its alloys) 250, aluminum 200, lead 140, nickel 500.

Titanium has a high melting point, a small thermal expansion coefficient, and poor thermal conductivity. Pure titanium has good plasticity, low strength, and is easy to process and shape. It can be made into filaments and thin sheets.

Titanium's oxidation resistance is better than most austenitic stainless steels. Pure nickel has excellent corrosion resistance and high-temperature oxidation resistance, and is an important engineering metal material.

Industrial pure nickel has good strength and conductivity. It can be used in electronic devices. At the same time, due to its good corrosion resistance, it can also be used in food processing equipment. Nickel alloys have further improved corrosion resistance and mechanical properties, and can also have special physical properties.

Corrosion-resistant nickel alloys, high-temperature-resistant nickel alloys and functional nickel alloys. For example, corrosion-resistant nickel alloys can be used in the fields of chemical industry, petroleum, shipbuilding, such as valves, pumps, ship fasteners, boiler heat exchangers, etc.. High-temperature-resistant nickel alloys are widely used in turbine disks and compressor disks of aircraft engines and launch vehicle engines.

First, let's study the thickness of steel plates.

According to the thickness, we can divide steel plates into thin plates (0.2mm-4mm), medium-thick plates (4mm-60mm) and thick plates (>60mm). The method of cutting steel plates of different thicknesses is also very particular. For example, when cutting into regular thin steel plates such as rectangles and triangles, you can choose a shearing machine, which is not only fast, quality guaranteed, but also low cost.

The non-ferrous metal shearing production line can process nonferrous metals: nickel plate, cobalt plate, copper plate, cold-rolled plate, hot-rolled plate, plain carbon steel, stainless steel, aluminum, etc.

Easy, convenient and quick to set and modify production process parameters; including speed, etc.; conveniently switch between manual, single-action and automatic modes, and monitor the operating status of each part.

The cantilever type is set on the unwinding machine seat, and the unwinding machine descends to press the steel coil and unwind it manually.

Correct the rolled metal sheet into a flat sheet. The leveling machine consists of a feed traction roller, an upper and lower leveling roller group, an upper and lower support roller, a frame, an upper row of roller pressure adjustment device, a transmission system, etc.

Level the sheet and release the internal stress of the sheet, improve the correction accuracy of the sheet, with a wide range of applications, no roller pressure marks on the surface of the material, and higher correction accuracy. This machine is used for continuous shearing of steel plates of a certain length according to requirements

The belt conveyor moves back and forth with the shearing movement of the mobile shear and conveys the steel plates to the fixed conveyor belt.

The long steel sheets sheared by the shearing machine are sent to this machine through the conveyor and collected neatly by air pressure and hydraulic pressure, and then transported out by the discharge roller. It is equipped with a support arm, a single-side plate beating and a tail plate beating, and a high-pressure blower to buffer the descending speed of the plate to reduce the damage to the plate surface.

The entire line is centrally controlled by PLC, the servo drive system feeds the material at a fixed length, and the DC speed regulator adjusts the working speed of the leveling machine and the shearing machine.

Non-ferrous metal shearing production lines are mainly used to shear non-ferrous metal materials such as aluminum, copper, nickel, titanium, etc. to meet the needs of subsequent production processes. Such production lines are usually used in industries such as metallurgy, automobiles, aerospace, electronics and construction.

Parameters | Indicators |

Applicable materials | Non-ferrous metals such as aluminum plates, copper plates, and titanium plates |

Sheet thickness range | 0.3mm - 12mm |

Sheet width range | 500mm - 2000mm |

Shearing speed | 20 - 60 times/minute |

Fixed length accuracy | ±0.1 mm |

Automation degree | Fully automated control |

Control System | PLC + touch screen |

Continuous automated operation, fast shearing speed and high production efficiency.

Adopting servo feeding and CNC system, the shearing size accuracy can reach ±0.1mm.

Fully automated from loading to stacking, reducing manual intervention and labor costs.

Can adapt to the shearing needs of non-ferrous metal plates of different thickness, width and material.

Anti-scratch design is adopted during transportation and stacking to ensure the surface quality of the plate.

Through sensors and PLC systems, the equipment status and shearing accuracy are monitored in real time to ensure stable operation.

If you have specific needs, such as the scale of the production line, the type of processing materials or the shearing accuracy requirements, you can provide further information and we will recommend a suitable solution or equipment configuration for you.