How thick can a 3000w laser cutting machine cut? We refer to laser cutting machines as fiber laser cutting machines, not CO2 laser engraving machines. The latter is mainly used for cutting non-metallic materials. Generally, the table top is relatively small, and the power of the fiber laser cutting machine is relatively high. The table top is also large, and it is used to cut various metal sheets, mainly for sheet metal processing, chassis processing, stainless steel cabinet processing, etc. Let's be specific about how thick the laser cutting machine can cut with 3000w.

The 3000W laser cutting machine is a high-power laser cutting equipment commonly used for cutting metal materials. It uses high-energy laser beams to focus on the surface of materials, causing them to quickly melt, vaporize, or burn, and removes the melted material with gas assistance, thereby achieving cutting. The following is a detailed introduction to the 3000W laser cutting machine:

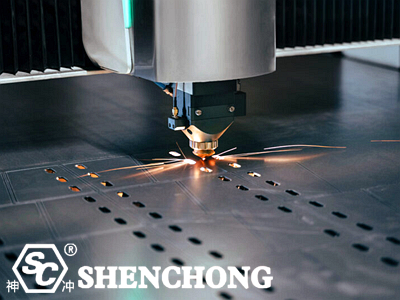

The laser used in the laser cutting machine emits a highly concentrated beam of light. The laser beam is focused onto the surface of the material, forming a high-energy density light spot. At this focal point, the material rapidly heats up and melts or vaporizes, while high-pressure gas blows away the molten or vaporized product, thus completing the cutting.

This is the core component that generates high-energy laser beams. Common types of lasers include fiber lasers, CO2 lasers, etc. The 3000W laser power is mainly used for cutting medium thickness metal materials.

Laser is transmitted to the cutting head through fiber optic cables, making energy more concentrated and reducing transmission losses.

Including focusing lens, nozzle, and gas assist system. Focusing lens concentrates the laser beam onto the surface of the material. The nozzle uses high-pressure gas (usually oxygen, nitrogen, or air) to cool and remove the molten material generated during the cutting process.

Modern laser cutting machines are equipped with advanced CNC (Numerical Control) systems that can accurately control cutting paths and speeds based on CAD drawings.

The 3000W power belongs to the medium to high power laser cutting machine, suitable for cutting medium thickness metal materials.

Depends on material thickness, material, and laser power. Thinner materials can be cut faster, while thicker materials can be cut slower.

- Carbon steel: 1mm thick carbon steel, with a cutting speed of over 30 meters per minute; 10mm thick carbon steel, with a cutting speed of approximately 1-2 meters per minute.

- Stainless steel: 1mm thick stainless steel with a cutting speed of approximately 18-20 meters per minute; When the thickness is 8mm, the speed will decrease to about 1 meter per minute.

- Cutting accuracy: Laser cutting has a very high precision, usually reaching ± 0.05mm to ± 0.1mm, suitable for the processing of high-precision parts.

- Cutting thickness: Depending on the material, the thickness that a 3000W laser cutting machine can cut is approximately:

(1) For carbon steel, the cutting speed of a 3000W laser cutting machine can reach 10-30 meters per minute.

(2) For stainless steel, the cutting speed of a 3000W laser cutting machine can reach 5-20 meters per minute.

(3) For aluminum alloys, the cutting speed of a 3000W laser cutting machine can reach 10-25 meters per minute.

(4) For non-ferrous metals such as copper and brass, the cutting speed of a 3000W laser cutting machine can reach 5-15 meters per minute.

The 3000W laser cutting machine is suitable for cutting a variety of metal materials, including:

Carbon steel: suitable for structural components and mechanical processing industries;

Stainless steel: widely used in the manufacturing of stainless steel products such as food machinery and chemical equipment;

Aluminum plate: used for lightweight design in the aerospace and transportation industries;

Copper and brass: Suitable for the production of electrical components, but due to their high reflectivity, they have high requirements for laser performance.

The cutting thickness of a 3000W laser cutting machine is affected by various factors, such as laser power, cutting speed, material type, etc. Generally speaking, a 3000W laser cutting machine can cut thicknesses ranging from 0.5mm to 20mm. Specifically:

(1) For carbon steel, the 3000W laser cutting machine can cut a thickness range of 0.5mm-20mm.

(2) For stainless steel, the thickness range that can be cut by a 3000W laser cutting machine is 0.5mm-12mm.

(3) For aluminum alloys, the thickness range that can be cut by a 3000W laser cutting machine is 0.5mm-8mm.

(4) For non-ferrous metals such as copper and brass, the 3000W laser cutting machine can cut a thickness range of 0.5mm-6mm. It should be noted that these data are for reference only, and the actual cutting effect is also affected by factors such as equipment performance and operating skills.

(1) 500W laser cutting machine can cut thickness: carbon steel thickness ≤ 6mm; Stainless steel thickness ≤ 3mm; Aluminum plate thickness ≤ 2mm; Copper plate thickness ≤ 2mm;

(2) The thickness that 1000W laser cutting machine can cut: carbon steel thickness ≤ 10mm; Stainless steel thickness ≤ 5mm; Aluminum plate thickness ≤ 3mm; Copper plate thickness ≤ 3mm;

(3) The thickness that 2000W laser cutting machine can cut: carbon steel thickness ≤ 16mm; Stainless steel thickness ≤ 8mm; Aluminum plate thickness ≤ 5mm; Copper plate thickness ≤ 5mm.

Laser cutting speed far exceeds traditional mechanical cutting, especially for cutting thin sheets, the speed is very fast.

Laser cutting has much higher accuracy than traditional cutting methods, with smooth edges and no burrs, reducing the need for subsequent processing.

The laser cutting machine can achieve cutting of any shape according to programming, especially suitable for mass production and customized processing.

Modern laser cutting machines are often equipped with automatic loading and unloading systems, further improving production efficiency.

During the laser cutting process, there is no direct contact with materials, resulting in less waste and pollution, and the working environment is relatively clean.

The 3000W laser cutting machine is widely used in:

- Automotive manufacturing: mainly used for cutting body panels, processing automotive parts, etc.

- Sheet metal processing: Laser cutting machine is an indispensable equipment in the sheet metal processing industry, used to make various metal shells, cabinets, etc;

- Mechanical manufacturing: used for producing mechanical parts, the precision and flexibility of laser cutting meet the processing requirements of complex parts;

- Shipbuilding: cutting ship hull steel plates, stainless steel components, etc;

- Aerospace: The precision and efficiency of laser cutting are suitable for the manufacturing of high standard parts in the aerospace field.

Laser cutting machines require regular maintenance to maintain efficient operation of the equipment. The main maintenance tasks include:

(1) Regularly inspect the performance of key components such as laser generators, optical systems, and cutting heads to ensure the normal operation of the equipment.

(2) Regularly clean optical components such as mirrors, focusing lenses, etc. to prevent dust and dirt from affecting the quality of the laser beam.

(3) Regularly inspect and replace auxiliary gases to ensure gas supply during the cutting process.

(4) Regularly inspect and maintain mechanical components such as machine tools and guide rails to ensure the stability and accuracy of the equipment.

(5) Regularly conduct overall inspections and maintenance of equipment, promptly solve problems found, and avoid equipment failures.

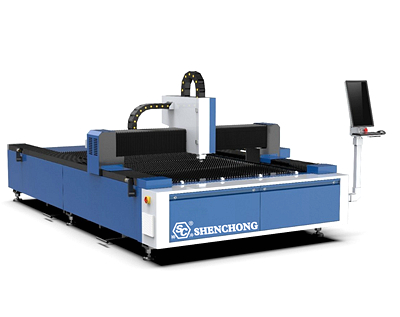

The SC 3000W sheet metal fiber laser cutting machine fro sale is a powerful industrial processing equipment, especially suitable for cutting metal materials. It has the advantages of high power, fast speed, and high precision, and is widely used in fields such as automotive, sheet metal, and mechanical manufacturing.