In recent years, as the upgrading of electronic products has accelerated, many home appliances and electronic instruments have focused on miniaturization and lightweight. In this environment, if sheet metal blanking is carried out according to the traditional stamping die processing method, not only the processing cycle will be long but the processing cost will be high. Therefore, the demand for flexibility in sheet metal processing is outstanding at this stage. At present, most of the production and processing methods in the sheet metal industry are still manual or semi-automated. Moreover, most sheet metal processing equipment has low utilization rates and low production efficiency, making it difficult to meet the rapid development of the sheet metal processing market.

How to ensure the efficient operation of processing equipment as much as possible in the production process of diversified products, reduce the operation losses caused by frequent production switching, and achieve the purpose of automated production? This is the key to improving production efficiency and the future development direction of the sheet metal processing industry.

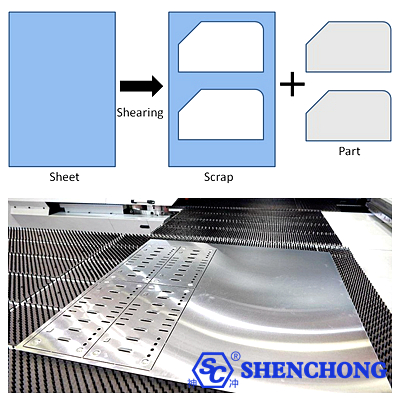

The sheet metal automated production studied in this article refers to the blanking part. It mainly analyzes and explains the aspects of blanking before programming, during programming, during production, and after production.

At this stage, the equipment used for sheet metal blanking mainly includes shears, laser processing machines, punches, and laser-punch composite machines, which can be selected according to the processing technology and dimensional accuracy of the product.

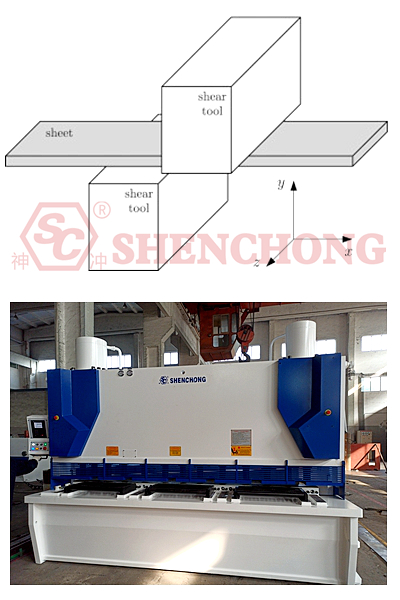

The plate shearing machine uses one blade to make reciprocating linear motion relative to the other blade to apply shearing force to metal plates of various thicknesses, so that the plates can be broken and separated.

The shearing machine can only process the outer dimensions of the board, but cannot process the internal dimensions of the board. In most cases, it needs to be used in conjunction with other equipment. The cutting shape of the CNC hydraulic shearing machine is very simple, but the straight line accuracy and quality of the processing are very high, and it is suitable for high-precision cutting and blanking.

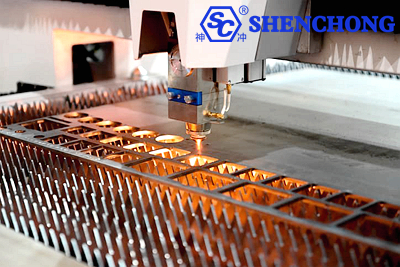

Laser processing uses light energy to reach a high energy density at the focus after being focused by a lens, and relies on the photothermal effect to process.

Laser processing does not require tools, has fast processing speed, small surface deformation of processed materials, and can process a wide variety of materials. However, when using a laser processing machine, it is necessary to select the appropriate processing auxiliary gas according to factors such as the processing material. This also indirectly increases processing costs.

And since the laser can only perform plane cutting, it cannot meet the processing needs of some special forming processes. When the equipment is replaced and reprocessed, there will be positioning errors in the secondary positioning of the plate, which will affect the dimensional accuracy of the product.

The processing principle of the punch press is to convert circular motion into linear motion through the operation of mechanical structures such as gears, crankshafts, and connecting rods, thereby achieving the effects of force transmission and pressurization. Therefore, punch processing must use a set of molds to complete the processing of materials through the pressure exerted by the machine tool.

However, since the punch machine can only perform punching processing, it is difficult to process special-shaped holes with complex shapes. If special-shaped punching molds are purchased, it will undoubtedly increase the processing cost for small batch production. If the equipment is replaced and reprocessed, there will also be the problem of secondary positioning error.

The laser punch combined machine combines the advantages of both. It can complete laser cutting and punch processing in one positioning. It has a higher degree of automation, but the investment cost will also increase accordingly. Therefore, for products with complex structures, laser punching composite machines are more suitable. For products with simple structures, the cutting equipment can be selected based on comprehensive considerations such as the structural characteristics and cost of the product.

When designing a product, the designer's priority must be the assembly performance of each part. However, while ensuring that the structural performance of the product is not affected, structural design such as process holes can be carried out based on the existing mold to reduce processing costs.

For example, when designing the support hole for the screw drawing process, the process hole can be designed to a size similar to the existing mold without affecting assembly use, thereby reducing the investment cost of the mold.

When designing the rear panel of a player, the heat dissipation holes of the product have no practical role in the structure, and there are usually a large number of heat dissipation holes. Laser processing time will increase significantly, indirectly increasing processing costs. Therefore, most of them are punched using molds. Without affecting the performance of the product, the heat dissipation holes can be designed to the existing mold size, thereby reducing mold investment, shortening the product processing time, and reducing product costs.

Special attention needs to be paid when designing round holes or special-shaped holes around the product's deep drawing, convex hull and other structures. If the hole is processed first and then the drawing process is carried out, it is easy to cause the hole to be deformed during the drawing process. If deep drawing is performed first and then a mold is used to process the hole, the pressing surface of the mold may interfere with the drawing structure, and a special mold is required to make way for processing. If laser cutting is used, the drawn structure may also collide with the laser cutting head. Therefore, when designing, it is necessary to fully calculate the amount of material flow around the drawing, and control the distance between the hole and the drawing structure to avoid adverse interference in production.

When designing the round hole around the bending line, it is necessary to consider that the material flow during the bending process may cause the round hole to deform, and the size between the hole and the bending line needs to be calculated.

When writing processing programs, you must first analyze the structural characteristics of the product to determine whether there are special processes, such as convex hull, deep drawing, bending, etc.

Usually product processing is carried out in the order of plane punching first, then forming processing, and finally laser cutting. But some product structures are more special. For example, for punching holes in deep drawing, the deep drawing forming process needs to be performed first, and then the punching holes are made. If the bending machine cannot process small-size bends, the material at the bend must be cut off to make way for the bend before bending. At this time, laser cutting needs to be performed first, and then the bending and forming process is performed. In response to these situations, programmers need to have clear arrangements for the processing sequence to avoid product size defects caused by chaotic processing sequences and ensure that the product size is qualified.

When programming the material manipulator to take out, try to ensure that the suction cup of the take-out manipulator is adsorbed on a flat position, avoiding the holes or forming surfaces of the product to ensure that the product does not fall. It is also important to note during this process that some suction cups exist in groups, and it is necessary to ensure that each suction cup in the entire group is reliably adsorbed. Otherwise, it may also cause the suction cup to have insufficient adsorption force, causing the product to fall during movement, affecting the progress of automated production.

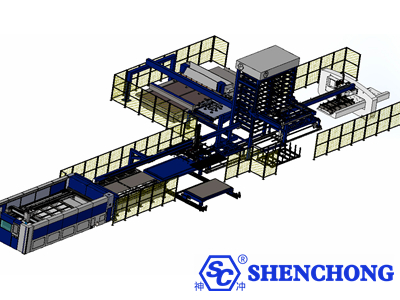

In order to achieve 24-hour unmanned automatic blanking production of products, on the one hand, we need reasonably optimized processing procedures, and on the other hand, we also need hardware support such as processing equipment.

Based on the processing time of the program and the time required for unmanned automated production, the required processing plates are calculated. It should be noted that when multiple processing procedures are jointly automated for production, attention should be paid to whether the processing materials between different procedures are of the same specifications to avoid downtime due to lack of processing materials.

The auxiliary gas has the functions of blowing off the cutting slag, cooling the processed parts, and protecting the cutting lens during the processing. When selecting processing auxiliary gas, it has a certain relationship with the type of processing material, thickness of processing material, processing cost and other factors.

Different auxiliary gases play different roles in processing. Commonly used gases include air, oxygen, nitrogen, and argon. No matter what kind of gas is used, it must be ensured that there is sufficient gas during the processing and that the gas is pure gas without water, oil, dust and other impurities.

According to all procedures that require automated processing, the molds to be used are placed on the processing turret in advance. For equipment without automatic mold replacement, when processing multiple programs, the molds on the same turret serial number must be the same. Otherwise, when switching programs, the product will be misprocessed, resulting in product processing dimensions that are inconsistent with the drawings, resulting in defective products, resulting in economic losses.

If you want to realize automated production, you also need to solve the placement problem of finished products. This requires the processing equipment to be equipped with an intelligent storage system to store the finished products and raw materials taken out by the robot. And before processing begins, the storage locations of products and raw materials are set according to the processing procedures to avoid program conflicts during production, causing confusion in product placement and affecting subsequent production and processing.

In actual production, we usually encounter situations where the processing program demonstration is normal but various alarm errors occur during the processing. This situation often occurs when the robot grabs the product and takes it out. This requires programmers and processing personnel to cooperate closely and sum up experience in order to better complete the automated production of blanking materials.

Before batch automated production, it is necessary to confirm the production of single-sheet processed products, including whether there is any missing processing, whether the burr size is qualified, whether the appearance is defective, etc. Although the previous production of the processing program was qualified, every time the program is switched, there may be interference with some parts of the next production program. Therefore, confirmation must be done before mass production.

Normally, the quantity of a product produced can be calculated based on the program. However, in the actual production process, poorly processed products sometimes appear due to various factors. For products without subsequent processing, this will make the actual quantity inaccurate and easily lead to confusion in the quantity of finished products.

For products with subsequent processing steps, although the number of processing completed in the previous process can be indirectly calculated based on the number of subsequent processing, if you want to achieve smarter and more efficient sheet metal automated production, you can choose IoT visual monitoring software to monitor the production according to your needs. Monitor and analyze the entire process. When a production defect occurs, the monitoring software will record it by itself and provide help with subsequent production quantities, which will help automated production move towards intelligent production.

At this stage, if you want to realize automatic production of sheet metal blanking, you need both software and hardware, and a certain amount of money is invested. For some small sheet metal processing companies, the investment and return are not directly proportional, and for some product demand For large enterprises with large products and many types of products, they can consider whether to invest according to their own needs. In general, it is a long and arduous process to realize automated production of sheet metal blanking.