The punching mold design is the core of the entire process. This will directly affect the hole shape, precision and surface quality of the product. The design of the punch mold should be based on the punching requirements, material properties and equipment capabilities to ensure that the ideal hole shape and arrangement are obtained while producing efficiently. The following is a detailed analysis of the punching mold design.

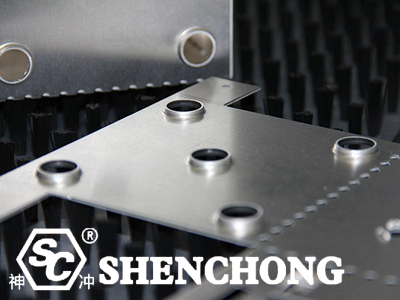

Punching dies are a kind of punching tool for metal or other materials. It usually consists of two parts: an upper die and a lower die. Pressure is applied by a press or other equipment to deform the material being processed under the action of the die, thereby forming holes or other required shapes.

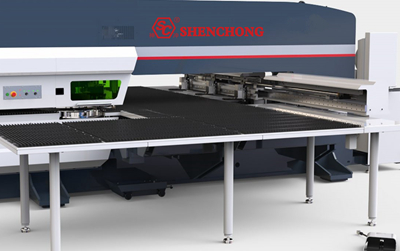

Punching molds are widely used in sheet metal processing, electronic products, automotive parts and other fields, and can complete mass production efficiently and accurately.

- Upper and lower dies: The upper die is responsible for applying pressure, while the lower die provides support and shape.

- Guide pins and guide sleeves: used to ensure that the upper and lower dies remain accurately aligned during processing.

- Punch pins: work with the lower die to actually cut or punch the material.

- Unloader: pushes waste or finished products out of the die after punching is completed.

Depending on the application, the metal punching mold can be designed in different shapes and specifications to suit specific processing needs.

There are many types of punching dies according to their structure, function and application field. The following are several common classifications:

Each punching can only complete one process, such as a single punching or cutting.

Suitable for the production of parts with simple structures, with low efficiency, often used for small batch production.

Multiple processes can be completed simultaneously in one punching stroke, such as punching, trimming and other operations.

Used for parts with high machining precision requirements and complex shapes, which can significantly improve production efficiency.

The material is punched multiple times in the die to complete different processes. Each time the material moves forward, it is punched once, and multiple processes are gradually completed.

Used for mass production of complex parts, which can significantly improve production efficiency and is widely used in the automotive, electronics and other industries.

Used to stretch flat materials into hollow shapes, such as cups, cylindrical parts, etc.

Suitable for the production of parts that require deep drawing, commonly used in home appliances, automobiles and other fields.

Specially used for punching materials to obtain parts of specific shapes.

Used to produce parts with regular shapes, suitable for mass production.

Change the shape of the material through processes such as bending, folding, and hemming, rather than just cutting or punching.

Used for the production of parts that require specific bending or complex forming, widely used in sheet metal processing and other fields.

One stamping operation completes multiple different processing processes, and stamps at multiple locations through the movement of the material.

Suitable for mass production of complex parts and improve processing efficiency.

Change the cross-sectional shape of the material through the extrusion operation in the die.

Mostly used to process parts with precise cross-sectional requirements, such as pipes, bars, etc.

The design of different types of metal punching molds varies according to factors such as product shape, processing requirements, and material properties. Choosing the right type of die can significantly improve production efficiency and product quality.

The selection of mold materials is crucial because the mold needs to withstand huge pressure and frequent friction when punching. Mold materials are usually required to have high hardness, high wear resistance and high toughness.

The selection of mold materials directly affects the wear resistance, strength, processing accuracy and service life of the mold. Reasonable material selection needs to be comprehensively considered based on factors such as the type of material being processed, the production quantity, and the working environment of the mold. The following are the main considerations when selecting punching mold materials.

The mold material needs to have a high hardness to ensure that it does not deform under high stress and can withstand long-term impact and compression.

When punching, there is friction between the mold and the workpiece surface, so wear resistance is an important factor in extending the life of the mold. Especially when punching materials with high hardness or strong wear resistance, the wear resistance of the mold material is particularly important.

The mold material should have good toughness under impact load to prevent cracking or breakage during impact, especially when large stress concentration is likely to occur during stamping.

During long-term use, the mold is repeatedly subjected to stress, so materials with good fatigue resistance can avoid mold failure problems such as cracks and edge collapse under repeated stress.

The mold material should have good heat treatment performance so that the hardness and toughness can be adjusted through heat treatment. In addition, the deformation of the material during heat treatment should be as small as possible to ensure the accuracy of the mold.

The mold material should have good cutting and processing performance so that it can be easily machined during manufacturing and repair.

Such as T8, T10, etc.: The price is relatively low, and the hardness and wear resistance are good after quenching, but the toughness is slightly poor. It is suitable for punching molds in small batch production and low stress working environment.

Such as Cr12, Cr12MoV, D2, etc.: This material has high wear resistance and hardness, suitable for molds in high strength and high stress environment, and is often used in mass production. Cr12MoV is a widely used material with excellent wear resistance and toughness.

Such as W6Mo5Cr4V2, W18Cr4V: High-speed steel has extremely high hardness and wear resistance, and is suitable for molds with very high requirements, such as high-speed punching molds. However, this material is more expensive and is suitable for molds with high precision requirements and long service life.

Such as YG20, YG15, etc.: Cemented carbide has extremely high hardness and very good wear resistance, and is suitable for materials with high stamping hardness and severe wear. Carbide dies are usually used for mass production, especially for punching some difficult-to-process materials such as stainless steel and titanium alloy.

Such as ASP23, ASP30, etc.: Powder metallurgy steel has a more uniform structure, and its wear resistance, strength and toughness are better than traditional tool steels. It is suitable for punching dies with high precision and extremely durable requirements.

Some special stamping occasions use different materials for inlay combination dies. For example, carbide is used on vulnerable parts, while other parts use materials with better toughness to reduce costs and extend the life of the die.

The selection of punching die materials should comprehensively consider hardness, wear resistance, toughness, fatigue resistance and machinability. Commonly used materials are carbon tool steel, alloy tool steel, high-speed steel, carbide and powder metallurgy steel. The material selection mainly depends on the specific stamping conditions, the characteristics of the processed materials and the production batch.

The sheet metal punching mold design and the selection of the hole shape are very important links in the stamping process, which directly affect the quality of the finished product, the life of the die and the production efficiency.

The mold design needs to be accurately calculated and reasonably arranged according to the shape, size, material, etc. of the punching hole. The following are the key points about hole shape and mold design.

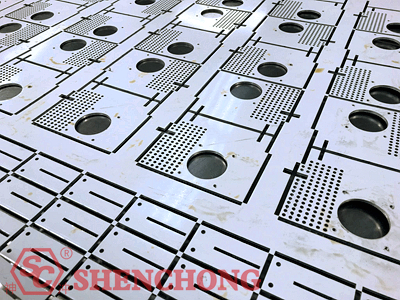

The hole shape refers to the shape of the hole required on the workpiece to be processed. Common hole shapes include round holes, square holes, elliptical holes, special-shaped holes, etc. Different hole shapes have different requirements for mold design.

Metal plate punching can be designed with a variety of different hole shapes. The specific choice depends on the functional requirements, appearance design, and application scenarios.

Common hole shapes include the following:

Features: The most common and easy to process, uniform punching force, and simple mold design.

Application: Widely used in ventilation holes, decorative holes, and structural parts that require high symmetry.

Features: The shape is regular, but stress concentration is prone to occur at the corners, and a suitable rounded corner design is required to reduce cracks.

Application: Suitable for structural parts that need to be firmly connected or fixed, widely used in mechanical equipment or decorative perforated plates.

Features: The punching process is more complicated, especially the ratio of the major axis to the minor axis should be appropriate, which is convenient for material arrangement.

Application: Used in scenes such as ventilation, filtration or decoration, and also used for connectors that need to be adjusted or slid.

Features: It can adapt to specific structural connections, especially when the position needs to be adjusted.

Application: It is widely used in connecting plates, adjustment devices, machined parts, etc.

Features: The shape is compact, which can maximize the spacing between holes while reducing material waste.

Application: It is commonly used in metal mesh, filters, ventilation devices, and is widely used in honeycomb structure design.

Features: Strong decorative effect, complex mold design, and easy to produce stress concentration.

Application: It is mainly used for decorative panels, lighting or other products with high appearance requirements.

Features: Similar to square holes, stress concentration is easy to occur at the corners, and small fillets are usually designed at the corners.

Application: It is used for decoration, specific connectors or mechanical parts that need to be fixed in direction.

Features: The hole shape is irregular, and it is difficult to design and manufacture. It is usually a customized product.

Application: It is used for products that require special functions or appearance designs, such as signboards, artworks, decorative parts, etc.

Features: Various shapes can achieve both aesthetic effects and enhance the mechanical properties of materials.

Applications: Commonly used in architectural decorations and filter screens, or in specific structural elements.

Features: Multiple small holes are arranged in lines or graphics to reduce the amount of material cutting.

Applications: Used for material ventilation, weight reduction or aesthetic purposes, such as exhaust nets, filter devices, etc.

Features: The shape is similar to Venetian blinds, usually made by continuous punching process, which can control the passage of light or airflow.

Applications: Suitable for vents, heat sinks and other application scenarios that require airflow or light regulation.

The hole shape design of metal plate punching can be diversified according to the needs of specific applications, from simple round and square holes to complex special-shaped holes, star-shaped holes and decorative hole shapes. Different hole shapes differ in mechanical properties, appearance effects and manufacturing difficulty, so the material properties, use environment and processing costs should be comprehensively considered during design.

Mold gap refers to the distance between the punch pin (upper mold) and the mold hole (lower mold). Reasonable design of the gap has a decisive influence on the punching quality and mold life.

- Too large a gap: the hole precision is poor, there are more burrs on the hole edge, but the mold life is long.

- Too small a gap: the hole precision is improved, the burrs are reduced, but the mold wears quickly and the life is shortened.

- Reasonable gap: calculated according to the thickness, hardness and required hole precision of the punched material, usually 5-10% of the material thickness is taken as the gap.

The guide mechanism is a device in the mold that ensures the alignment of the upper and lower molds. Commonly used guide structures include guide pin and guide sleeve structures, which can reduce mold offset during the punching process, maintain the precision of the mold, and avoid punching deviation.

During the punching process, the punched material needs to be removed from the mold. The design of the unloading device includes elastic unloading plates, fixed unloading plates, pneumatic unloading and other methods to ensure that the workpiece or waste can be smoothly demolded after the die stamping is completed.

The hardness of the die should be determined according to the material being processed. Hard materials require higher die hardness to reduce wear, while softer materials do not require too high hardness to avoid die brittle cracking.

During the stamping process, air needs to be discharged from the inside of the die in time to prevent rebound or hole deformation caused by air compression during punching. Therefore, vents need to be designed at appropriate locations when designing the die.

The life of the die is related to many factors in the design, such as material selection, processing technology, cooling and lubrication measures, etc. When designing the die, the wear resistance of the material and the rationality of the processing technology determine the durability of the die. The stress concentration points should be minimized in the design to avoid fatigue failure of the die during use.

Punching force is a very important parameter in mold design. The size of the punching force affects the strength, structural design and selection of the CNC plate punching machine. The punching force is usually calculated by the following formula.

F=S×t×τ

F = Punching force

S = Perimeter of the hole

t = Material thickness

τ = Shear strength of the material

According to the size of the punching force, the thickness and strength of the mold can be reasonably designed, and the appropriate press can be selected.

The cutting edge of the mold needs to be rounded or sharp cornered to avoid stress concentration.

In the design of square holes or special-shaped holes, the corners are usually designed to be rounded to disperse stress and extend the life of the mold.

In processing scenarios that require very high precision, sharp corners may be designed to meet the precision requirements, but this usually reduces the durability of the mold.

In the design of complex hole shapes, the discharge of waste is also an important link. The mold is usually designed with a waste discharge port or guide groove to prevent waste accumulation from affecting processing. Complex-shaped waste may require a specially designed waste discharge channel or an automatic waste discharge system.

The design of the punching die and the selection of the hole shape is a complex process that requires consideration of many factors such as the type of hole shape, material properties, and production quantity. Through reasonable clearance, guidance, unloading, waste discharge and rounded corner design, the accuracy and life of the mold can be significantly improved, and the smooth progress of the punching process can be ensured.

The layout design of holes affects the complexity of the mold and the punching efficiency. When designing the mold, a reasonable layout design should be made according to the purpose and requirements of the punching plate.

Suitable for symmetrical structures or decorative designs, the hole spacing and hole diameter must be strictly consistent, and it is often used for filter screens or ventilation holes.

Used for products with specific design requirements, such as automotive parts, building decorative panels, etc.

When designing the mold, special attention should be paid to the distance between holes to avoid too close contact, which will lead to reduced mold strength or plate deformation.

Click here ton know more about: Sheet Metal Punching Hole Arrangement Design

The punching gap in the punching mold refers to the gap between the punch and the die. Reasonable punching gap design directly affects the punching quality, mold life and processing efficiency.

It will cause large burrs on the edge of the hole, poor precision, and serious deformation of the plate.

Although it can reduce burrs, the mold wears faster, which can easily lead to mold damage and reduced punching efficiency.

Usually, the design of the punching gap is determined based on the material thickness, material and stamping accuracy requirements. The common blanking clearance design standard is 5%-10% of the material thickness.

Click here to know more about: Punching Force Calculation And Molds Clearance

In mold design, the design of lubrication and cooling systems must be considered. During the punching process, the high-frequency contact between the mold and the material will generate a lot of heat, which will cause the mold to wear more and the product quality to decline.

Therefore, the mold usually needs to be dissipated and lubricated by lubricating oil or coolant to extend the life of the mold and improve the product quality.

The punching mold design should not only consider the production process, but also the convenience of its maintenance and repair. The mold will gradually wear out during long-term use, especially the punching of high-hardness materials. When designing, the convenience of mold decomposition and replacement of parts should be considered to reduce maintenance time and cost.

In order to maintain the sharpness of the punch and die, the mold needs to be polished regularly.

Some mold designs allow only part of the wearing parts to be replaced after damage, without replacing the entire mold, reducing maintenance costs.

The core of metal punching mold design lies in accuracy, durability and efficiency. Through precise punch and die design, reasonable blanking clearance and material selection, and effective lubrication and cooling systems, the mold can maintain efficient operation for a long time to ensure that the punching quality meets the requirements.