As we all know, the focus of the factory is production management. What does production management really care about? Fundamentally speaking, the means for a factory to complete orders and deliver products is production. Therefore, the task of production management is to ensure that the progress can be kept up, the cost can be controlled, and the efficiency can be improved.

The core idea of MES system design is to improve the production cycle as much as possible, reduce production costs and improve product quality.

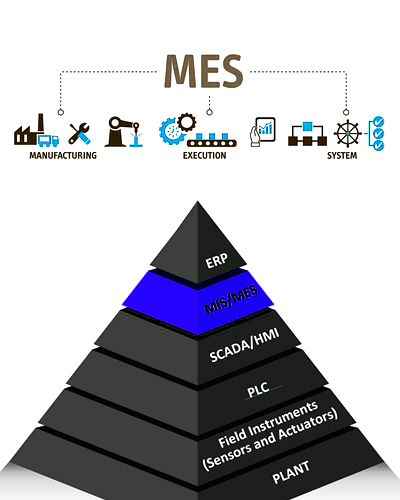

MES system production management is an important part of manufacturing informatization. It is the bridge between ERP and the underlying automation system. It is a workshop level information platform.

Integrating production scheduling, data collection, quality control, document management, performance management and other related functions, it provides a unified management platform for controlling all plant resources, including materials, equipment, personnel, process instructions and facilities.

It can provide enterprises with a refined and flexible production and manufacturing management environment. It can help enterprises flexibly schedule production, reasonably arrange production capacity, improve production efficiency, monitor the production process in real time, and reduce costs and material losses.

So as to improve the product quality and on-time delivery ability of enterprises, and realize the agility of production and manufacturing process.

MES is a series of management functions, rather than a simple software system. It can be a collection of various production management functions.

MES system focuses on solving production process control, error prevention, fool prevention, quality traceability, equipment operation and other related management objectives. The details are as follows.

As a connecting link, it completes the seamless integration of all information systems (such as ERP, PLM), automatic control systems (such as sheet metal, production lines) and equipment (such as bending machines, shearing machines) linked with MES systems. Integrate upstream and downstream information flow through MES system to establish a production management platform with unified business, smooth process and standardized data.

Combined with ERP system, establish an advanced planning system. Formulate a detailed scheduling plan under resource constraints such as capacity and materials. Unified command and control of materials, personnel, process instructions, equipment and other factory production resources.

MES system should cover some WMS functions, and realize the production logistics management together with the automated logistics system (such as automated warehouse, AGV trolley, etc.).

In the digital factory, unmanned automatic material flow is realized. The MES system directs and tracks material flow, manages material consumption, prepares material feeding plans, etc., and adopts work order and batch management to achieve material tracking and feedback.

Quality control takes the collection and control of quality information in the production process as the core. Establish fast and efficient quality feedback, quality processing and quality tracking control throughout the whole process. MES system automatically generates various quality reports, factory test reports and other data.

Based on the data acquisition system of the whole plant, establish an integrated control system, including electronic signage, SCADA system integration, monitoring center and andon system. Display all kinds of field data of the whole production process in real time. According to the pre-set conditions, in case of abnormal conditions, the alarm should be timely reminded, and take corresponding scheduling measures.

Collect and analyze the use frequency, operation status, working hours, quota, energy consumption, capacity and other relevant information of the main production equipment in the workshop. Carry out comprehensive operation and research management of the equipment, so as to maintain the intact rate of the equipment and give full play to its efficiency.

Perform statistics and analysis on real-time data. Through comprehensive analysis of a large amount of data, we can effectively evaluate the production operation. Thereby, it provides powerful measures for optimizing organization, improving output and quality, improving equipment capacity and reducing production cost. For example, employee performance management, calculation of piece rate wages, equipment efficiency classification, etc.

Support mobile terminals such as mobile phones and PDAs, and realize the dispatch, work reporting, material receiving, material issuing, data entry, production progress tracking, real-time statistical analysis and display of mobile terminals.

MES is the hub of smart factory. It plays a very important role for the whole enterprise. But MES is not omnipotent. It is mainly aimed at the information system of production site management. MES system will also take into account equipment, warehouse, logistics and other aspects, but all information is production centered. It provides service support for production.

The boundary between MES and other systems is sometimes not so clear, and it is constantly evolving. Future MES may integrate more functions.

Finally, let's talk about the current situation. On the one hand, because of intelligent production and the transformation of the enterprise itself, customers need MES as a support to strengthen workshop management, improve production efficiency and do lean production.

Second, the MES system is also a requirement of large enterprises. We need the products produced by enterprises to be traceable throughout the process and the quality can be controlled. The functions of MES system can realize these.

And now, intelligent manufacturing enterprises, including the automotive, furniture, and electronic industries, have launched MES systems production management. The whole society is also promoting intelligent production, giving enterprises financial and policy support, and with great efforts. So that more enterprises can launch MES system, enhance their competitiveness and drive the development of the global economy.

At present, due to the epidemic, the overall economy is affected. Some enterprises are relatively cautious about the investment in MES system. However, some enterprises take intelligent production as a way to deal with the current difficulties, and develop their own research and development or find MES service providers to do customized development.