The hydraulic shear blade is a necessary tool for cutting metal plates. Especially when cutting stainless steel products. The blade edge must be sharp, wear-resistant and ductile.

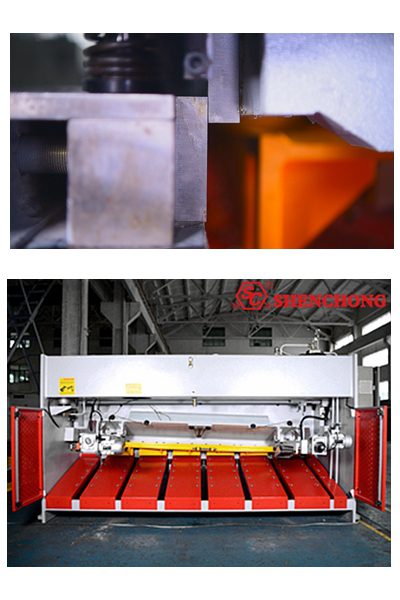

The blade of plate shearing machine is an important part of the whole equipment. Its material and processing directly determine the using life and cutting effect. Therefore, the quality of the cutting blade is the key to the plate shearing effect.

Many people believe that the higher the raw material of the hydraulic shearing blade, the better the product will be. In fact, the material of the blade depends on the plate to be sheared. The cutting will be smoother only if the material is selected correctly.

Hydraulic shear blades made of T10 (carbon tool steel), Cr5Mo (chrome-molybdenum alloy steel for high-temperature environments), and 9CrSi (low-alloy tool steel) are suitable for cutting ordinary A3, ordinary low-carbon cold-rolled plates and scraps. In addition, shear blades made of 9CrSi are also suitable for cutting harder thin steel plates.

The shearing machine blades made of 6Crw2si (steel grade formed by adding a certain amount of tungsten to chromium silicon steel) and Cr12MoV (cold work die steel) are suitable for cutting hot-rolled plates, stainless steel, and medium-thick plates.

Blades made of 4Cr5MoSiV1 (air quenched and hardened hot work die steel), 7Cr7Mo2V2Si (high strength and toughness cold work die steel), W6Mo5Cr4V2 (high carbon and high alloy tool steel suitable for high-speed cutting), etc. are suitable for high-speed and high-temperature hot shearing. The material features high temperature resistance and is not easy to anneal.

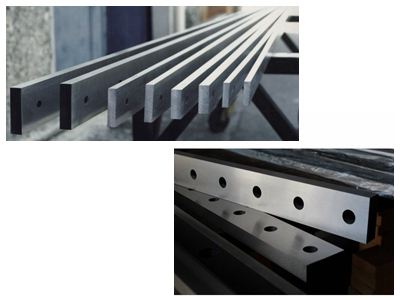

In industrial production, there are generally two kinds of edges commonly used for the blade of plate shearing machine accessories. One is 90°, commonly known as "flat knife edge". The other is 82°, commonly known as "oblique knife edge".

The difference between the two is that the edge of the plate cut by the blade of the oblique shearing machine is more regular and beautiful than the blade of the flat shearing machine. It is often used to cut thin plates on the hydraulic pendulum shearing machine.

As the stress area of the blade of the beveled plate shears is small, it is easy to crack when it is used to cut thick plates. If the customer has a high demand for the cut boards, it is necessary to select the beveled blade with better material. In this way, we can not only meet the needs of customers, but also avoid the phenomenon of edge collapse due to the thickness of the plate.

How to distinguish whether the shearing blade is inclined or flat? We can measure it with a 90 ruler. If it's parallel, it means it's a flat shearing blade. If there is a gap and a viewpoint, it's the oblique cutting blade. Here, it should be noted that at present, the lower edge of the blade of the hydraulic shearing machine is 90 flat on all sides.