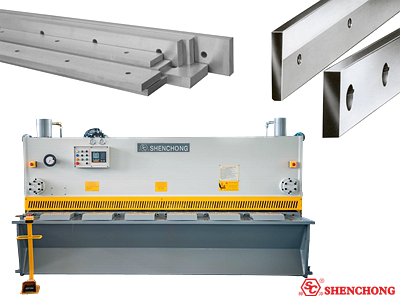

The CNC hydraulic shearing machine has been used for a long time, and the plate shear blades are worn out, which affects the normal production of the equipment. At this time, we need to disassemble the shearing machine blades in time and install them after repairing them. How do these two steps work?

A. Start the hydraulic shear machine, adjust the cutting angle to 1.0 °, and adjust the gap between the cutting blade to 0.48mm;

B. After the hydraulic shear machine knife rack running management several rounds, turn off the machine tool and disconnect the total power supply of the hydraulic shear machine;

C. Remove the fence of the hydraulic shear machine and foot press (pay attention to prevent the overflow of hydraulic oil) and the rail;

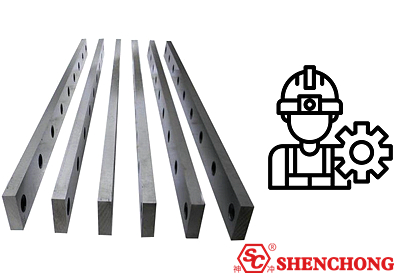

D. First remove the lower blade of the hydraulic shearing machine: loosen all the screws on the lower blade, use a long wooden square to force the lower blade against the back of the machine tool to prevent the lower blade from falling backwards or slipping, and remove the screws on the lower blade , and then pull out the lower blade from the side of the hydraulic shearing machine;

E. Finally, remove the upper shear blade: loosen all the mounting screws of the upper blade, place two suitable wooden squares between the workbench and the upper blade, and press the blade firmly, remove the screws on the upper blade, and then gradually loosen the pads into the wood , pull out the blade from the side of the hydraulic shearing machine.

The order of the upper and lower blade of the hydraulic guillotine shear machine is the opposite of the order of removing the plate shear blade.

A. When installing the cutting blade, the sharpened blade will be sharper, so the operator needs to be very careful, and it is best to wear gloves for management

B. Upper shear blades installing: Firstly, install the upper blade, screw on the upper shearing blade with M12*40 screws, do not install the screws at both ends temporarily, hold the upper blade with a wooden stick, make the contact surface between the top of the upper blade and the slider fully adhere, and then tighten the installed M12*40 screws on the upper blade, drop the slider to the bottom dead point, turn off the oil pump motor, then install the M12*40 screws on the left and right ends of the upper blade, and tighten them. The tightening torque of the blade screws is 35N/M.

C. Lower plate shear blades installing: First of all, start the oil pump to raise the slider to the upper dying point. After turning off the oil pump, install the lower blade, screw it with the hexagonal screw in the M12*45 (do not twist too tightly), press the knife with a wooden stick, so that the lower shear blade is pressed, so that the lower bottom is used to make the bottom below. The knife and the cutting blade on the workbench are fully tight, and the M12*45 screw is tightened as required.

D. Finally, install the cover plate, foot press and guard rail of the hydraulic shearing machine.

E. After installation, it is necessary to adjust the cutting angle and knife edge clearance back into the original value to ensure the accuracy and consistency of cutting.

The above is the removal and installation steps of the blade of the hydraulic guillotine shearing machine. When the operator is actually operating, be sure to wear protective gloves to ensure safety. Hope this sharing is helpful to everyone.