At present, with the rapid development of society, the labor cost of enterprises is rising. At the same time, management costs and difficulties are also rising. As a result, many companies are constantly upgrading automatic production equipment. And the share of intelligent workshops is increasing.

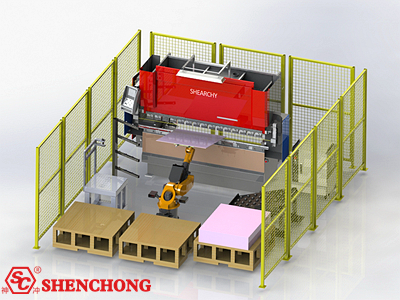

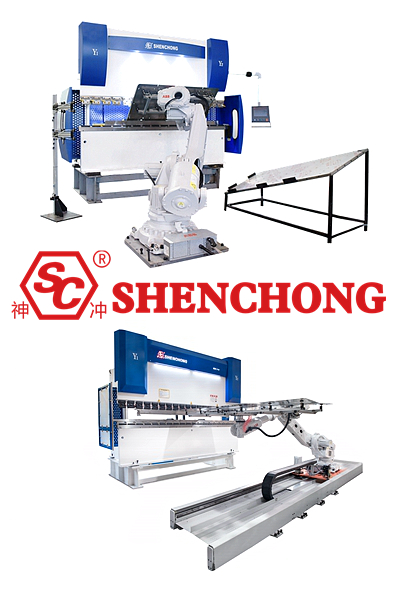

In the field of sheet metal processing, six axis special automatic bending robot is most used to replace the process of manual bending. However, not all enterprises are suitable for robot automatic bending.

The robotic press brake manufacturer needs to deeply understand the customer's on-site working conditions before making recommendations in the communication with users. Here are some important points for your reference.

![]()

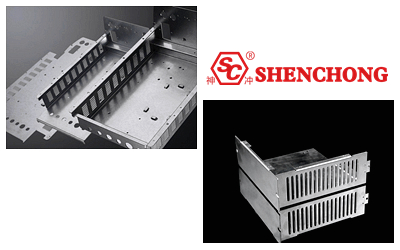

The automatic bending robot is more suitable for the workpiece price with relatively large area size. For example, the bending of 28 cabinets, electric control cabinets, communication cabinets, etc.

Its biggest advantage is that it can work 24 hours a day without interruption. In addition, it can greatly improve the overall efficiency and productivity.

For manual bending, because the product size is relatively large, the physical strength of workers is very high. Moreover, the bending of a product requires more than one person to complete. People need regular rest, diet, and leave in the middle, which will have a certain impact on personal safety.

However, if the product size is relatively small, the bending process is simple, and the quantity is not large, we do not recommend using automatic robotic bending. In this case, it takes a considerable amount of time to teach and adjust the robotic press brake. As long as the manual workers know what the bending process is like, they can start to work immediately. And there is no need for centering and retrieving like robot bending. At this time, the efficiency of manual bending will be much faster than robot bending.

Click here: Comprehensive Analysis: Robotic Bending System

A set of robotic press brake bending unit is recommended to make workpieces with similar size and large quantity. Although it can theoretically cover all bending parts of the enterprise, the cost will increase a lot, such as the need for multiple sets of suction tools.

During product replacement, if it is necessary to change the suction device, it will take up a part of manpower to replace the suction device. Although it can be solved by quick-change, the cost will be much higher. If the number of bending machines in the factory is not relatively small, we suggest that a bending robot only make the products with similar size and large output.

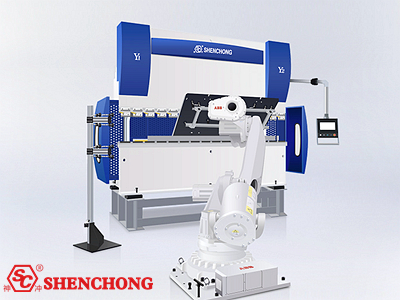

If the product size is relatively large or there are other reasons for the large area to be bent, the seventh axis (also known as the ground rail) shall be added after the bending robot body is selected. In this way, the working range of the automatic bending robot can be expanded to meet the bending requirements of more size products.

Also, if customers want to minimize human intervention, adding the seventh axis can reduce the time for workers to change the suction tool. In addition, the maintenance of the seventh shaft can be solved by installing an automatic oiler. This can not only save labor costs, but also ensure the normal operation of the equipment. Therefore, the service life of the equipment will not be reduced due to human neglect.

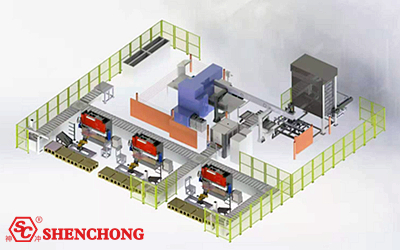

In summary, the automatic bending robots are suitable for the processing of large size, large weight, single variety and large batch of workpiece. This type of processing plant is very suitable for fully automatic robot bending production.

- The manipulator follows the CNC bending action synchronously.

- High tracking accuracy ensures that the workpiece does not deform.

- Multi-axis linkage, full servo control.

- Save labor costs and greatly improve productivity.

- High efficiency and full automation.

- 24-hour processing automation: automatic loading and unloading, automatic robot bending.