Cold stamping is one of the most common material forming methods in sheet metal manufacturing. We deeply analyze it form: characteristics, types, shapes and materials.

Cold stamping is one of the basic methods of plastic working. Let's analyze the "cold stamping process" in depth and sort out the application steps.

Cold stamping is one of the basic methods of plastic working. It is a pressure processing method that uses a mold installed on a press to apply pressure to the sheet metal at room temperature to deform or separate it, thereby obtaining parts with a certain shape, size and precision.

Let's analyze the "cold stamping process" in depth and sort out the application steps.

- It can punch out complex shapes that are difficult or impossible to process by other processing techniques.

For example: from small parts of instruments to large parts such as automobile panels and longitudinal beams. They are all completed by stamping.

- Stamping parts have stable quality and high dimensional accuracy.

Because the stamping process is formed by molds. The mold has high manufacturing precision and long service life, so the quality of stamping parts is stable and the parts are interchangeable.

The dimensional accuracy can generally reach IT10~IT14 grades. And the highest can reach IT16 grades. Some parts can meet the assembly and use requirements without mechanical reprocessing.

- Stamping parts have the characteristics of light weight, high strength, good rigidity and small surface roughness.

- High productivity.

For example: the production efficiency of large stamping parts such as automobile panels can reach several pieces per minute. High speed stamping of small parts can reach thousands of parts per minute.

- High utilization rate of materials.

Generally 70% ~ 85%. Therefore, stamping processing can achieve less waste, or even no waste production.

In some cases, the leftover materials can also be fully reused.

- Simple operation, easy to organize production.

- It is easy to realize mechanized and automated production.

Because most of the blanks used in stamping are sheets or strips, and they are processed in cold state, it is easy to realize mechanization and automation in mass production.

- The cold stamping die has a long manufacturing cycle and high manufacturing cost. So it is not suitable for single-piece small batch production.

Due to the different shapes, sizes and precision requirements of stamping parts. Therefore, the methods of cold stamping are various.

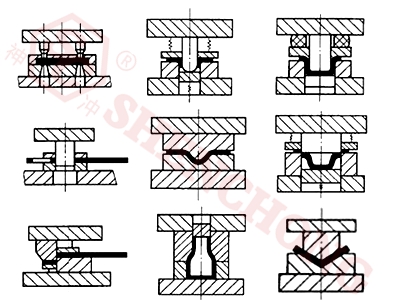

According to the deformation characteristics of the material and the current habits of the enterprise, the basic process of sheet metal cold stamping can be divided into two categories: separation and plastic deformation.

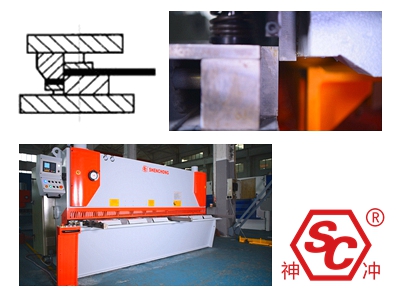

The separation process is a stamping forming method to separate the stamping parts from the sheet along the required contour and obtain a certain section quality.

The separation process is as follows:

Cut the sheet metal with scissors or die, and the cutting line is not closed.

Blanking: use the die to punch the sheet metal along the closed line, and the punched part is the work piece.

Punching: use the die to punch and cut the sheet along the closed line, and the punched part is waste.

In this way, the sheet metal is partially cut but not completely separated by the die, and some materials of the cut are bent.

The excess material at the edge of the workpiece is punched and cut off with a die.

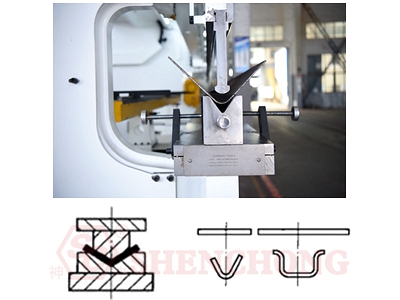

The plastic deformation process is a stamping processing method to make the stamping blank plastic deformation under the condition of no fracture, so as to obtain the parts with the required shape and size.

The deformation process is as follows:

Undulations (ribs): The sheet is partially stretched into convex and concave shapes with a die.

Flanging: Use a mold to turn the hole or outer edge of the sheet into a straight wall.

2) Necking

Apply radial pressure from outside to inside to the mouth of the hollow part with a die to reduce the local diameter.

Apply outward radial force to the hollow part with the die to expand the local diameter.

Flattens the uneven surface of the workpiece; pressing the original bent or drawn part into the correct shape.

In order to improve labor productivity, two or more basic processes are often combined into one process, which is called a compound process.

Most of the materials for cold stamping are sheets, strips and blocks of various specifications.

- The size of the sheet is large, and it is generally used for stamping of large parts.

- For small and medium-sized parts, most of the sheets are cut into strips for use.

- Strip material, also known as coil material, has various widths, and the unfolded length can reach tens of meters.

- Automatic feeding suitable for mass production: the material thickness can also be made into strip supply.

- Blocks are only used for stamping of a few steel grades and expensive non-ferrous metals.

- Ferrous metal: ordinary carbon structure, high-quality carbon structural steel, alloy structural steel, carbon tool steel, stainless steel, etc.

- Non-ferrous metals: pure copper, brass, bronze, aluminum, etc.

- Non-metallic materials: cardboard, glue board, rubber board, plastic board, fiberboard and mica, etc.

- Requirements for stamping materials

- Formability

Good shaping, small yield ratio and small plate thickness direction coefficient. The ratio of yield strength to elastic modulus is small

Note: the materials in the separation process need some plasticity, but they don't need to be very good. The better the plasticity, the harder it is to separate.

- Material thickness tolerances

Conform to international standards.

- Surface quality

The surface is smooth and clean, free from delamination and damage to mechanical properties. No rust spots, scale and other attachments.

Sheet metal cold stamping is one of the most common material forming methods in manufacturing. When using the stamping method to make parts, it is completed through a series of processes. It is very important to select the most suitable process. If you think our in-depth analysis is useful, please actively forward and continue to pay attention!