Industrial production line automation can not only liberate people from heavy physical labor, some mental labor, and harsh and dangerous working environments. Moreover, it can expand human organ functions, greatly improve labor productivity, and enhance human beings' ability to understand and transform the world. The development of enterprises such as machinery and equipment, electronic production, petrochemical industry, light textile industry, catering, medicine, military manufacturing, automobile industry, etc. are all inseparable from the leading and supporting role of automated production lines.

The automated production line is developed based on the continuous improvement of automated special machines.

The automated machine is a single piece of automated equipment that can only complete a single process in the product production process. Features are limited. After completing a certain process, the completed semi-finished products need to be manually transferred to other special machines to continue the next production process.

Completing the entire production requires a series of special machines with different functions and manual participation. This not only reduces the site utilization rate, but also increases the number of production employees and equipment, which also increases the production cost, which is not conducive to the improvement of product efficiency and quality.

If a series of different automated special machines required for product production are arranged in the order of the production process, all the special machines can be connected through the automated conveying system, eliminating the need for manual participation between the special machines.

The product production process is that after a special machine completes the corresponding process operation, the completed finished product and production process information will be automatically transmitted to the next special machine through the conveyor system to continue the new process operation until all processes are completed.

This not only reduces the manpower and material resources required for the entire production process, but also greatly shortens the production cycle, improves production efficiency, reduces production costs, and ensures product quality. This is the background of automated production lines.

The automated production line is an automatically working electromechanical device system that is gradually developed based on the functions of the assembly line and automated machines.

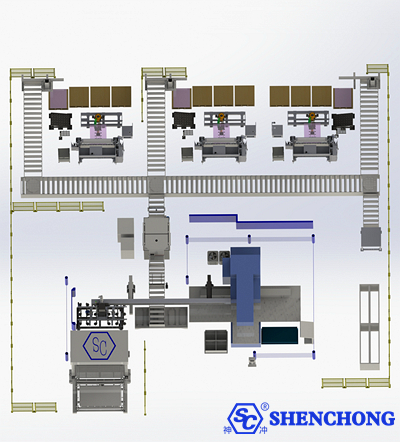

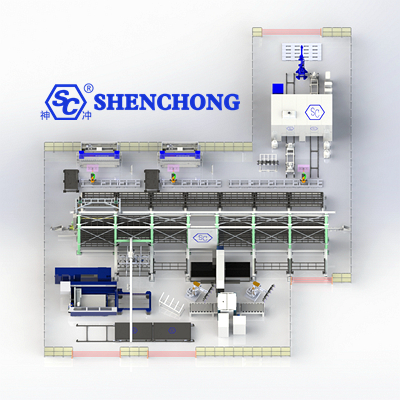

It connects various automated special machines into one through automated conveying systems and other auxiliary devices according to specific production processes, and makes all parts act jointly through pneumatic, hydraulic, electric motors, sensors and electrical control systems. The entire system is made to work automatically according to prescribed procedures, and to continuously and stably produce specific products that meet technical requirements. This mechatronics system that works automatically is called an automated production line.

The development of mechanical equipment, electronic production, petrochemical industry, light textile industry, catering, medicine, military manufacturing, automobile industry and other enterprises are inseparable from the leading and supporting role of automated production lines. Automated production lines are the lifeline of modern industry.

The conditions that usually qualify for the use of industrial automated production lines are: high product demand, the need for mass production, stable product design, because automatic production lines cannot adapt to frequent design changes, long product life, usually multiple operations, involving the use of multiple workstations .

Industrial automated production lines are typically used for high production volumes of parts that require multiple machining operations. The production line itself consists of geographically dispersed workstations within the factory that are connected by a mechanized work transport system with automated systems that transport parts from one workstation to another in a predetermined production sequence. In the case of machining operations, such as drilling, milling and similar rotating tool processes, are carried out at specific workstations.

The development of mechanical equipment, electronic production, petrochemical industry, light textile industry, catering, medicine, military manufacturing, automobile industry and other enterprises are inseparable from the leading and supporting role of automated production lines. Automated production lines are the lifeline of modern industry.

There are three types of automation in industrial production line: fixed automation, programmable automation and flexible automation.

An industrial automated production line consists of distributed workstations connected by a mechanized work transfer system that moves parts from one workstation to another as they enter the system. The cost of automated production lines is relatively high. As an example of fixed automation, the layout of industrial automated production lines is relatively difficult to change. Once it is established in a production factory environment, it is not easy to change its layout.

To sum up, whether automated production lines can improve production efficiency depends on many factors, including the company's production needs, product types, production line technology, management level and employee skills. Although automated production lines have the advantage of improving production efficiency, they also have some disadvantages and limitations. Therefore, companies need to consider these factors comprehensively when choosing automated production lines to ensure that they choose the solution that best suits their needs.

When improving productivity, it's beneficial to look at the entire system design, identify bottlenecks, and work to overcome them. A good automated system can solve these problems.

A simple example of a production part is how ingredients are metered. Let's say you have a product that consists of ten different ingredients, and the current system measures each ingredient separately. An industrial production line automation system that meters all ten ingredients simultaneously will increase the speed of each production run.

The total cost of industrial production line automation includes the cost of raw materials, labor, energy consumption and waste. This will not change over time. However, in the fiercely competitive market, the cost of not being able to enter the market in time, the cost of losses caused by failing to meet current consumer needs, and the cost of maintaining stable high quality.

Today, product quality is closely related to accuracy and repeatability. If metering is inconsistent over time, it affects the consistency of the product. A good industrial automation system will help processors ensure the consistency of products being manufactured every day, while monitoring for glitches or failures in product quality and consistency.

The industrial automatic production line automatically operates or controls the process according to prescribed procedures or instructions without human intervention. Its goal is to be "stable, accurate, and fast." The use of automatic production lines can not only liberate people from heavy physical labor, partial mental labor, and harsh and dangerous working environments, but also expand human organ functions, greatly improve labor productivity, and enhance human beings' ability to understand and transform the world. .

Products produced using industrial automated production lines should have sufficiently large output. Product design and technology should be advanced, stable, reliable, and remain basically unchanged for a long time. The use of automatic lines in mass and mass production can improve labor productivity, stabilize and improve product quality, improve labor conditions, reduce production area, reduce production costs, shorten production cycles, ensure production balance, and have significant economic benefits.