Metal processing manufacturers often face the problem that highly reflective materials such as copper, aluminum, and titanium are difficult to cut. Can fiber laser cutting machines laser cut high-reflectivity raw materials? Why is laser cutting reflective metal brass and copper so challenging? What should I pay attention to?

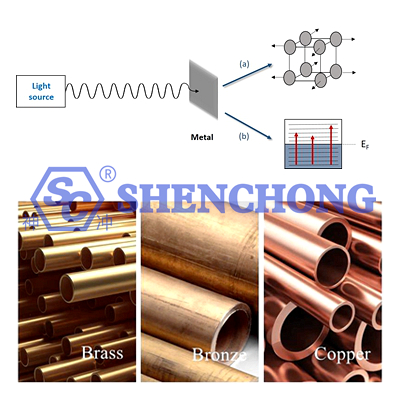

As the name suggests, reflective metals are metals that reflect wavelengths directed toward them. Copper, brass, bronze, silver, gold, and aluminum are highly reflective of infrared light when in the solid state. Reflective metal can direct the light that hits it back to its source. This is called "tempering". If you use a general laser cutting machine to cut forcibly, it will damage the equipment and cause huge losses.

Reflective metals are used in many industries around the world, such as the electronics, automotive, aerospace and semiconductor industries. Fiber laser cutting ensures the high quality and reliability of cutting and is widely used in these industries.

Brass and copper have low absorption of infrared laser light, making these metals difficult to cut. Copper and brass (copper-zinc alloys) are good reflectors (and therefore poor absorbers) of infrared (IR) lasers, especially in the solid state. Pure copper reflects >95% of near-infrared radiation (approximately 1 μm wavelength) when in the solid state. The reflectivity of copper and other reflective metals decreases as the metal heats up, and drops dramatically after the material melts (e.g., molten copper drops below 70%).

Some people have tried to solve this problem by applying non-reflective coatings to the metal, but the molten metal created during laser cutting is itself reflective. This means that no matter how much non-reflective coating is used, it will damage the laser.

Gas lasers especially struggle with yellow metals such as copper or brass. Laser cutting of mild steel and stainless steel has a long history and has always been one of the main applications of CO2 laser. However, CO2 lasers have traditionally not provided a good solution for cutting reflective metal materials.

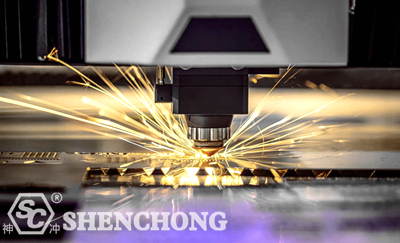

Fiber laser cutting is the most cutting-edge technology in laser cutting and is an effective solution for processing reflective metals. This technology does not use mirrors, gases or sophisticated lenses, but instead uses fiber optics to deliver the beam. This means that the reflective properties of metal do not pose a risk of damage to the laser as is the case with gas or crystal lasers.

Fiber lasers emit at a wavelength of about 1.07 μm, compared with 10.6 μm for traditional CO2 alternatives. The 1.07 μm laser is less reflective and therefore easier to absorb. And shorter wavelengths can be focused into a spot about 1/10 the diameter of the CO2 beam. This provides great power density, making metal cutting easier.

At such high power density levels, metals such as copper and brass rapidly undergo a phase change into a molten state, and the laser beam quickly overcomes the reflectivity barrier of such metals, initiating an efficient cutting process.

When an optimized laser, optics, and cutting process are selected, the laser beam quickly melts the surface of the reflective material and then interacts with the more absorbent molten metal, initiating an efficient, stable cutting process. Incorrect selection of laser and optics, or use of non-optimal process parameters can cause the laser to rest too much on the solid metal, resulting in excessive back-reflected light. Too many reflections can in turn cause the cutting process to be inefficient and possibly damage optics.

The critical stage for laser cutting reflective metal is the beginning of the process, specifically the piercing stage when the laser interacts with the solid metal. After creating the cut, the laser beam interacts primarily with the molten material.

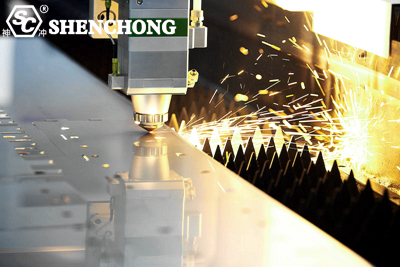

The following process parameters are relevant for piercing and cutting copper and brass with fiber lasers:

The process can support approximately 10–15% more support compared to the maximum feed rate to avoid the risk of kerf burnout, allowing high levels of beam energy to be applied on the most reflective materials. If you have concerns, you can start at a lower speed and allow enough dwell time to ensure a through hole before moving the beam to start cutting.

For both piercing and cutting, the focus position should be set as close to the top surface as the quality of the cut allows. This minimizes surface material to interact with the beam at the beginning of the process, thereby maximizing the power density of the beam and melting the material faster.

Using the maximum peak power available for piercing and cutting reduces the time the material is in its most reflective state.

When laser cutting highly reflective materials, some auxiliary gas must be added to increase the cutting speed. When a metal laser cutting machine cuts metal copper, the added auxiliary gas reacts with the material under high temperature conditions to increase the cutting speed. For example, using oxygen can achieve a combustion-supporting effect.

Nitrogen is an auxiliary gas for laser cutting equipment to improve the cutting effect. For copper materials below 1MM, it is completely possible to process them with a metal laser cutting machine. When the thickness of metallic copper reaches 2MM, it cannot be processed if only nitrogen is used. At this time, oxygen must be added to oxidize it before cutting can be achieved.

When perforating and cutting copper, high-pressure oxygen is often used as the cutting gas to improve process reliability. When oxygen is used, the copper oxide that forms on the surface reduces reflectivity. For brass, nitrogen works well as a cutting gas.

Highly reflective metal materials have always been difficult to cut with metal laser cutting machines, including copper, aluminum, gold, etc. These materials are also common materials in our daily processing. After years of development, laser cutting technology can sometimes process highly reflective materials, but the relevant conditions and standards must be strictly followed to ensure cutting quality.

Of course, the safest and safest way to cut high-reflection metal in a straight line is to use a high-quality hydraulic guillotine shear. At normal temperatures, the hydraulic guillotine shearing machine can cut various high-reflection metal plates with high speed and precision without causing deterioration or damage.

New Energy Cobalt Plate Cutting Automation Unit

Nickel Plate Automatic Shearing Unit: High Speed & High Precision