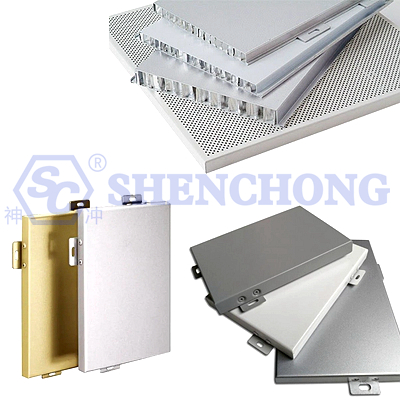

Aluminum veneer refers to a building decoration material that is processed using fluorocarbon spraying technology after chromation and other treatments. After aluminum veneer forming and spraying, it can be used in various industries. Aluminum veneer has good corrosion resistance, oxidation resistance, heat resistance, cold resistance and other properties. After we process it through CNC press brake machine, it can be used in various construction and decoration industries.

The structure of aluminum veneer is mainly composed of panels, reinforcement ribs, corner codes and other components. The maximum molding workpiece size can reach 8000mm×1800mm (L×W).

- Conventional thickness: 1.5mm, 2.0mm, 2.5mm, 3.0mm.

- Common specifications: 600X600mm, 600X1200mm.

- Light weight, good rigidity and high strength.

- Good durability and corrosion resistance.

- Uniform coating and various colors.

- Not easy to stain, easy to clean and maintain.

- Installation and construction are convenient and quick.

- Can be recycled and reused, which is environmentally friendly. Aluminum panels are 100% recyclable, unlike glass, stone, ceramics, aluminum-plastic panels and other decorative materials.

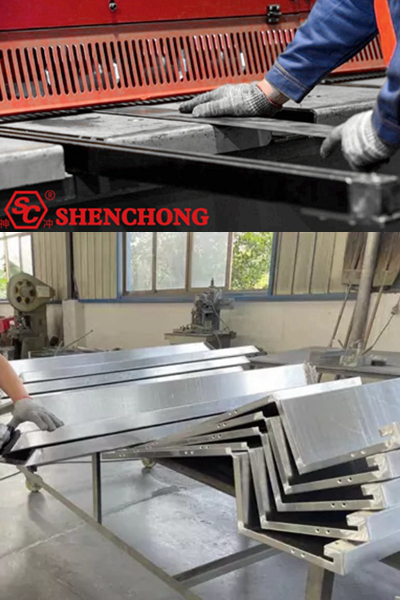

The processing and production of aluminum veneer is divided into two major steps: the first is sheet metal forming processing.

This aluminum veneer forming process mainly involves cutting, bending, rolling, welding, grinding and other processes on the flat plate. Process the aluminum veneer into the shape and size required for construction. This step requires the use of various sheet metal processing equipment, such as CNC hydraulic bending machines, shearing machines, plate rolling machines, electric welding machines, etc.

The second step is to spray. When aluminum veneer materials are processed and produced, aluminum veneer manufacturers use multi-layer spraying techniques for their appearance, which can better play the role of aluminum veneer materials.

At present, there are three main spraying processes commonly used by aluminum veneer manufacturers: electrostatic powder spraying, polyester paint spraying, and fluorocarbon paint spraying. The prices of the three spraying technologies are also different. The characteristics of these three spraying technologies are introduced below:

Its main components are polyurethane, epoxy resin, etc. It is characterized by simple spraying construction, impact resistance, friction resistance, and good corrosion resistance. Its biggest weakness is the fear of ultraviolet radiation from the sun. Aluminum veneer will naturally deteriorate if exposed to the sun for a long time. Fading, resulting in serious color difference. Generally, obvious color difference will appear after three to five years of use.

Polyester paint, also called unsaturated polyester paint, is a thick paint made of TECHNOLOGY 61 polyester resin as the main film-forming substance. The advantages of polyester paint are high solid content, good hardness, beautiful color and strong corrosion resistance. The disadvantage is that the weather resistance is not that good, and the resistance to sunlight and ultraviolet rays is relatively weak.

The main component of fluorocarbon paint is polyvinylidene fluoride resin nCH2CF2 baked (CH2CF2)n (PVDF) as aggregate, and the chemical structure of fluorine in the fluorocarbon base material is combined with carbon. In addition to its strong wear resistance and impact resistance, fluorocarbon paint has the characteristics of anti-fading and strong UV resistance in harsh climate environments, so that aluminum veneers will not cause serious discoloration when used on exterior walls, so they are often used in outdoor curtain walls.

From the perspective of the aluminum veneer production process, the main steps of the multi-layer spraying process are:

Firstly, the primer coating of the aluminum veneer is carried out, then the topcoat coating is carried out, and then the varnish coating is carried out to perform the corresponding curing effect treatment on the appearance of the aluminum veneer material.

Primer coating is a primer finish that seals the aluminum veneer substrate. As an intrinsic decorative process, this layer is mainly used to improve the anti-penetration strength of the coating during further painting.

The aluminum veneer material is protected as the first layer through primer coating. This can not only stabilize the surface effect of the material, make the coating effect have good uniformity, but also improve the adhesion effect between the topcoat material and the metal plate. Generally, the thickness of primer is controlled at about 5 to 10 microns.

Topcoat coating is spraying the corresponding color on the surface of the aluminum veneer, which is an important step when decorating. The topcoat coating is directly applied to the surface of the aluminum veneer material and is operated according to the design requirements.

The topcoat coating can not only add decorative effects to the appearance, but also beautify the aluminum veneer material, making it more suitable for building decoration needs. At the same time, it can prevent the aluminum veneer material from direct contact with external air, making it immune to acid rain, pollutants, etc., and delaying the aging rate of the material. Generally, the thickness of topcoat is required to be controlled at about 20 to 30 microns.

The varnish coating is also commonly referred to as the varnish coating. The main reason for varnishing is to increase the resistance of the coating to the external environment and better protect the integrity of the topcoat. Enhance the gloss effect of its surface and keep the color shiny and bright. The thickness of the varnish coating is generally required to be about 5 to 10 microns.

This is a further consolidation of the three-layer coating, giving it a better decorative effect. This step requires keeping the aluminum alloy material in a curing furnace for high-temperature consolidation, with the temperature controlled between 180 and 250 degrees Celsius. Of course, different aluminum veneer manufacturers will control the temperature and duration to a certain extent based on the materials they produce and other conditions.

The above is the spraying process of aluminum veneer. Once completed, the multi-layer coating production of aluminum veneer material is basically completed.

The aluminum veneer processed by the spraying process can not only resist acidic and alkaline substances, such as acid rain, salt spray and other air pollutants, but also resist strong ultraviolet radiation. It can not only maintain colorfastness but also be used for a long time. We use plate shears to cut plates into different sizes for use in construction and construction. Purchasing SC high-precision CNC shearing machines can effectively improve the cutting accuracy and speed of aluminum veneer manufacturers!