The working principle of waterjet cutting is based on the physical properties of high-pressure water jets. Water is pressurized to extremely high pressure and ejected at high speed from a small nozzle, using the impact force of the water stream to cut materials. This water stream has very strong cutting power and can cut a variety of materials, such as metal, stone, glass, ceramics, rubber, composite materials and some flexible materials.

Waterjet cutting is a technology that uses high-pressure water to cut materials. This technology is achieved by increasing the water pressure to an extremely high level (usually over 60,000 psi, about 4000 bar), and then shooting the water through a small nozzle to form a high-speed water stream. This water stream has a very strong cutting ability and can cut a variety of materials, such as metal, stone, glass, ceramics, rubber, composite materials and some flexible materials.

The working principle of waterjet cutting machine is based on the physical properties of high-pressure water jets. Water is pressurized to extremely high pressure and ejected at high speed from a small nozzle, using the impact force of the water flow to cut materials.

This technology can cut a variety of materials and is particularly suitable for cutting heat-sensitive or flammable materials. The specific working process is as follows:

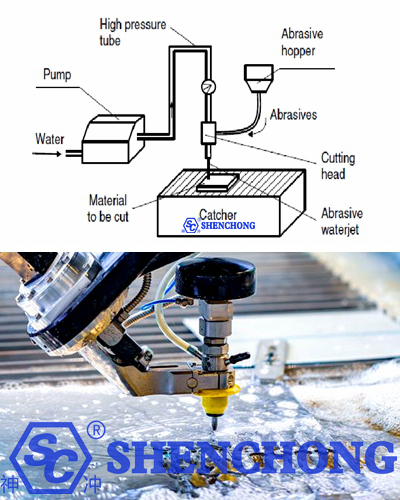

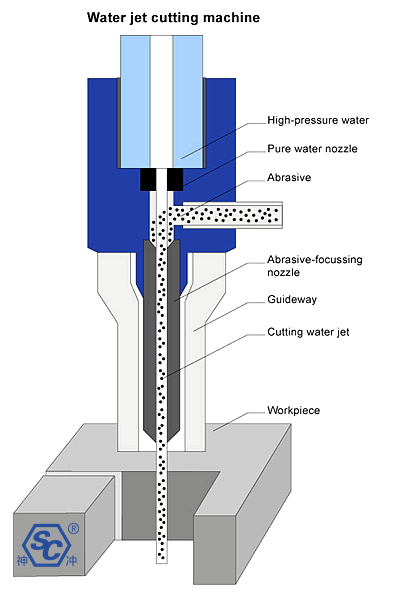

The core of waterjet cutting lies in the high-pressure water pump system. First, water is pressurized to extremely high pressures through a high-pressure pump, usually up to 4000-6000 bar (400-600 MPa) or even higher. This high-pressure water pump is responsible for converting ordinary water into a high-pressure water stream with strong impact force.

The pressurized water flow is ejected at high speed through a very small nozzle (usually 0.1-0.4 mm in diameter). The nozzle further accelerates the water flow to form an extremely fine and fast water jet, whose speed can reach two to three times the speed of sound.

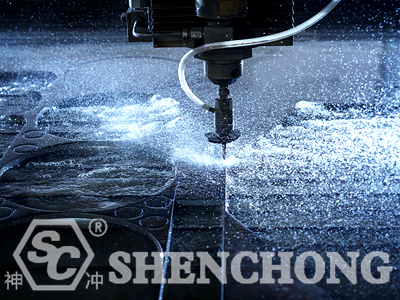

When the high-speed water jet contacts the surface of the material, the kinetic energy of the water is converted into impact force, which acts on the material, causing tiny cracks on the surface of the material and gradually expanding, thereby achieving cutting. This process does not generate heat and avoids the heat-affected zone, so it is particularly suitable for cutting heat-sensitive materials.

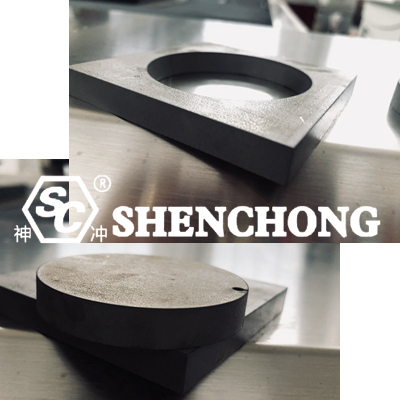

In order to cut harder or thicker materials (such as metal, ceramic, stone, etc.), abrasives (such as pomegranate sand, corundum) can be added to the water flow. This technology, called abrasive water jet, increases the cutting ability of the water jet with the assistance of abrasives, and can easily cut hard materials.

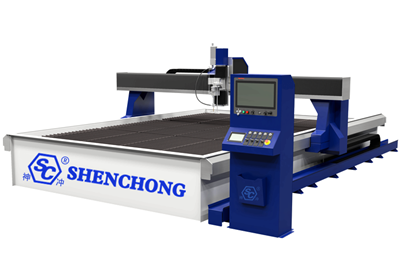

Water jet cutting is usually controlled by a numerical control (CNC) system, and the operator can accurately control the cutting path, speed and depth through programming. The CNC system can accurately perform cutting operations according to the design drawing to achieve high-precision processing.

Waterjet cutting can be used for processing a variety of materials, including metals (such as steel, aluminum, titanium), glass, plastics, composite materials, ceramics, rubber, etc. Due to the lack of thermal effects, water jet cutting has been widely used in aerospace, automobile manufacturing, architecture and art design.

Waterjet cutting machine uses the powerful impact of high-pressure water jets or abrasive water jets to physically cut various materials. Its advantages are no thermal effects, adaptability to a wide range of materials and high precision, and it has become one of the important cutting technologies in modern manufacturing.

The advantages of water jet cutting are mainly reflected in the following aspects:

Water jet cutting does not produce high temperature, so it will not cause thermal deformation, ablation or melting of the material, which is especially important for some heat-sensitive materials (such as certain metals, plastics and composite materials).

Water jets can cut almost any material, including metals with higher hardness (such as titanium, steel), non-metals (such as stone, glass, ceramics) and flexible materials (such as rubber, foam). This is not easily achieved by other cutting methods (such as laser, plasma cutting).

Water jet cutting can achieve very high precision, usually within ±0.1 mm. The cutting edge is usually very smooth, reducing the need for secondary processing.

Water jet cutting does not produce harmful gases or fumes, and the waste in the cutting process is mostly water and fragments of the cut material, which will not pollute the environment.

Since waterjet cutting is performed by water pressure rather than mechanical force, no mechanical stress is applied to the material during the cutting process, avoiding deformation or breakage of the material.

Waterjets can cut complex shapes and contours, suitable for a variety of custom processing needs. This makes waterjet cutting very popular in prototyping, artistic creation and small batch production.

The kerf of a waterjet is usually very fine (can be less than 1 mm), reducing material waste, which is especially important when cutting expensive materials.

Since there is no mechanical force acting on the material during cutting, complex fixture systems are usually not required, which simplifies operation and reduces costs.

These advantages have made waterjet cutting widely used in many industries such as aerospace, automotive manufacturing, construction, and medical devices.

The characteristics of a water jet cutter are mainly reflected in the following aspects:

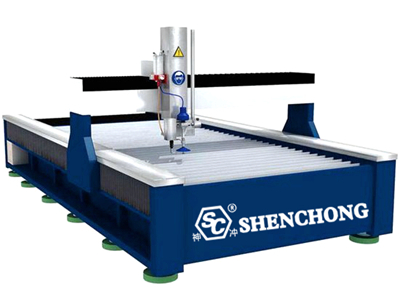

One of the core components of a water jet cutter is a high-pressure water pump, which is able to raise the water pressure to an extremely high level (usually between 30,000 and 90,000 psi) to provide sufficient cutting power.

Waterjet cutters can cut almost all types of materials, including metal, glass, ceramics, stone, rubber, composite materials, etc. This makes water jet cutters widely used in multiple industries.

Water jet cutting is cold cutting through high-pressure water flow, which does not generate heat, so it does not cause thermal deformation, ablation or other thermal effects of the material.

Water jet cutters can achieve high-precision cutting, usually achieving an accuracy of ±0.1 mm. The slit of the water jet is very fine, generally around 0.5 mm, which reduces material waste.

No harmful gas or smoke is produced during the water jet cutting process. The cutting waste is mainly water and fragments of the cutting material, which has little impact on the environment. It is a relatively environmentally friendly cutting technology.

The waterjet cutting machine can cut complex shapes and contours without changing the tool or making additional settings, and is suitable for various customized processing needs.

Modern water jet cutting machines are usually equipped with CNC systems, which can realize automatic operation through programming, improving production efficiency and cutting accuracy.

The structure of the water jet cutting machine is relatively simple, mainly high-pressure water pumps, nozzles and cutting platforms, etc., with low daily maintenance requirements and reasonable operating costs.

When cutting materials with higher hardness or greater thickness, water jet cutting machines usually add abrasives (such as pomegranate sand) to the water flow to enhance cutting ability. This technology, called abrasive water jet, expands the application range of water jet cutting.

The water jet cutting machine can cut materials of different thicknesses, from thin sheets to thick plates, with strong adaptability. At the same time, it can easily adjust the cutting speed and cutting pressure to adapt to different cutting needs.

These characteristics make waterjet cutting machines widely used in precision machining, prototyping, large structure cutting and other fields, becoming an indispensable part of industrial production.

Click here to know other information about waterjet cutting:

Laser Cutting Machine Or Waterjet Cutting Machine? Should it be an alternative?

CNC Water Jet Cutting Machine Guide: Working Principle And Features