Agricultural machinery is widely used in farming and other agricultural activities. Manufacturing agricultural machinery requires a range of specialized agricultural machinery manufacturing equipment to handle various aspects of the production process. The agricultural machinery production and manufacturing involve several key steps, from design and prototyping to assembly and quality control.

Agricultural machinery refers to a wide range of machines and equipment used in farming and other agricultural activities. These machines are designed to improve efficiency, productivity, and safety in various tasks involved in crop production, animal husbandry, and other agricultural operations.

Here are some common types of agricultural machinery:

- Description: Versatile vehicles that provide the power needed to pull and operate other farm machinery.

- Uses: Plowing, tilling, planting, and hauling.

- Description: Implements with blades used to cut and turn the soil.

- Uses: Preparing the soil for planting by turning over the top layer, burying weeds and crop residues.

- Description: Implements with spikes or disks used to break up and smooth the soil surface.

- Uses: Pulverizing soil, removing weeds, and preparing seedbeds.

- Description: Machines designed to distribute seeds evenly and at the correct depth in the soil.

- Uses: Planting crops like corn, soybeans, wheat, and others.

- Description: Equipment used to apply pesticides, herbicides, and fertilizers to crops.

- Uses: Protecting crops from pests and diseases and providing nutrients.

- Description: Machines used to gather mature crops from the fields.

- Types: Combines (for grains), balers (for hay), and forage harvesters.

- Uses: Harvesting crops like wheat, corn, rice, and hay.

- Description: Machines that compress cut and raked crops into compact bales.

- Uses: Making bales of hay, straw, or silage for storage and transport.

- Description: Equipment used to supply water to crops.

- Types: Sprinklers, drip systems, and pivot irrigation systems.

- Uses: Ensuring crops receive adequate water for growth.

- Description: Machines with teeth or shanks used to stir and pulverize the soil.

- Uses: Controlling weeds and preparing the soil for planting.

- Description: Machines that separate grains from their husks or straw.

- Uses: Processing crops like rice, wheat, and barley after harvesting.

- Description: Machines used to cut and condition grass or forage crops.

- Uses: Making hay or silage.

- Description: Machines that mix feed ingredients uniformly.

- Uses: Preparing balanced feed rations for livestock.

- Description: Technology-enhanced machinery that uses GPS, sensors, and data analytics.

- Uses: Optimizing field-level management, improving crop yields, and reducing input costs.

- Description: Unmanned aerial vehicles equipped with cameras and sensors.

- Uses: Monitoring crop health, surveying fields, and applying inputs precisely.

- Description: Self-driving tractors, harvesters, and other machines.

- Uses: Performing farming tasks with minimal human intervention, increasing efficiency.

- John Deere Tractor: Used for a wide range of farming tasks.

- Case IH Combine Harvester: Efficiently harvests grain crops.

- New Holland Baler: Creates compact bales of hay or straw.

- Kubota Rice Transplanter: Plants rice seedlings in paddy fields.

- CLAAS Forage Harvester: Harvests forage crops for silage.

- Agricultural machinery is essential for modern farming, helping to increase productivity, reduce labor, and improve the overall efficiency of agricultural operations.

The production and manufacturing of agricultural machinery involve several key steps, from design and prototyping to assembly and quality control.

Here's an overview of the process.

Conceptualization: Engineers and designers create initial concepts based on market needs, technological advancements, and feedback from farmers.

Computer-Aided Design (CAD): Detailed designs are created using CAD software, allowing for precise specifications and simulations.

Prototyping: Initial prototypes are built to test the design in real-world conditions, and adjustments are made based on performance.

Material Selection: High-quality materials such as steel, aluminum, and composite materials are chosen for durability and efficiency.

Procurement: Raw materials and components are sourced from suppliers. This can include engines, hydraulic systems, electronics, and other parts.

Fabrication: Raw materials are cut, shaped, and formed into specific parts using techniques like welding, machining, and stamping.

Component Manufacturing: Specialized components such as gears, shafts, and hydraulic cylinders are manufactured either in-house or by subcontractors.

Sub-Assembly: Smaller components are assembled into larger modules, such as engines, transmissions, and chassis.

Main Assembly Line: Modules are brought together on the main assembly line, where the agricultural machinery is assembled piece by piece. This can include mounting the engine, installing the transmission, attaching the wheels, and integrating electronic systems.

Automation: Many modern factories use robots and automated systems to improve precision and efficiency in the assembly process.

Inspection: Each stage of the manufacturing process includes rigorous inspections to ensure parts meet quality standards.

Testing: Finished machinery undergoes extensive testing, including performance tests, durability tests, and safety checks.

Certification: The machinery is certified to meet industry standards and regulatory requirements.

Painting and Coating: The machinery is painted and coated to protect against corrosion and to provide an aesthetic finish.

Branding: Logos, decals, and other branding elements are applied.

Packaging: The finished machinery is carefully packaged for transportation.

Shipping: Machinery is shipped to dealers or directly to customers.

After-Sales Support: Manufacturers provide after-sales support, including training, maintenance, and spare parts supply.

Continuous Improvement: Feedback from users and advancements in technology drive continuous improvement in design and manufacturing processes.

Example Machinery Production Process:

For instance, manufacturing a tractor might involve:

Frame and Chassis Construction: Building the strong frame and chassis that supports the tractor.

Engine Assembly: Installing a powerful engine that provides the necessary horsepower.

Transmission System: Adding a transmission system that allows for gear shifting and speed control.

Hydraulic Systems: Integrating hydraulic systems for attachments like plows or harvesters.

Electronic Systems: Installing modern electronics for navigation, control, and automation.

The process is complex and requires coordination between various departments, including engineering, production, quality control, and logistics, to produce reliable and efficient agricultural machinery.

Manufacturing agricultural machinery requires a range of specialized equipment to handle various aspects of the production process.

Here are the primary types of equipment used in this industry:

CAD Software: For creating detailed designs and simulations.

3D Printers: For rapid prototyping and testing design concepts.

CNC Machines: For precise manufacturing of prototype components.

Forklifts: For moving heavy materials and components around the factory.

Cranes: For lifting and positioning large parts during assembly.

Conveyor Systems: For efficient transportation of parts and assemblies through the production line.

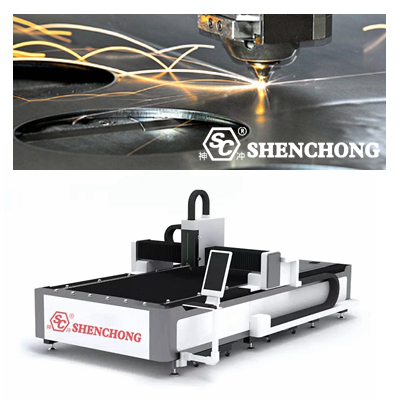

Laser Cutting Machines and Plasma Cutting Machines: For cutting metal sheets into precise shapes.

Press Brakes: For bending and forming metal sheets.

Lathes and Milling Machines: For machining parts to exact specifications.

Welding Machines: For joining metal components, including MIG, TIG, and robotic welding systems.

Assembly Lines: Configured for sequential assembly of machinery components.

Automated Guided Vehicles (AGVs): For transporting parts and sub-assemblies to various stations.

Robotic Arms: For precision assembly tasks, such as screwing, bolting, and fitting parts.

Hydraulic Presses: For assembling parts that require forceful fitting.

Spray Booths: For painting and coating machinery parts to protect against corrosion and enhance appearance.

Powder Coating Systems: For applying durable and even coatings to metal parts.

Coordinate Measuring Machines (CMM): For precise measurement of components to ensure they meet design specifications.

X-Ray and Ultrasonic Testing Equipment: For detecting internal defects in welds and castings.

Dynamometers: For testing the performance of engines and other mechanical systems.

Electrical Testing Equipment: For ensuring the functionality of electronic systems and components.

Test Rigs: For simulating field conditions and testing the performance of assembled machinery.

Hydraulic and Pneumatic Test Equipment: For testing the integrity and performance of hydraulic and pneumatic systems.

Calibration Tools: For ensuring accuracy and precision in measurement instruments and manufacturing equipment.

Shrink Wrap Machines: For protecting machinery during transport.

Palletizers: For stacking and securing products on pallets.

Loading Docks and Ramps: For efficient loading and unloading of machinery.

Tool Rooms: Equipped with a variety of tools and equipment for maintenance and repair.

Lubrication Systems: For maintaining machinery and production equipment.

Diagnostic Equipment: For identifying and troubleshooting issues with manufacturing equipment.

For a factory manufacturing tractors, the setup might include:

Heavy-Duty CNC Machines: For machining engine blocks and transmission components.

Robotic Welding Stations: For assembling the tractor frame and chassis.

Automated Paint Booths: For applying durable coatings to protect against environmental wear.

Engine Test Cells: For running and validating engine performance under load conditions.

Assembly Line with Robotic Arms: For efficiently assembling the tractor with high precision.

Each piece of equipment plays a crucial role in ensuring the agricultural machinery is built to high standards of quality, performance, and durability.