With the development of technology, people's demands for storage efficiency are becoming increasingly high. Sheet Metal Intelligent Warehouse have many advantages such as saving land area, improving storage efficiency, and management level, so the demand for the use of automated vertical warehouses is also increasing. How to choose sheet metal intelligent warehouse?

As an advanced warehousing method, Sheet Metal Intelligent Warehouse use automated equipment to store and retrieve goods, reducing labor and time costs, and improving work efficiency. Therefore, they have been increasingly widely used.

However, some customers may not have a deep understanding of this intelligent storage system and may encounter various problems during the selection process.This article will discuss the issues that should be paid attention to in the selection and construction of Sheet Metal Intelligent Warehouse.

The capacity of a Sheet Metal Intelligent Warehouse, including the total amount of items stored and temporarily stored in the warehouse; It is also necessary to consider factors such as the type of goods stored, weight, size, etc. Different types of goods may require different storage conditions and facilities.

The ability of logistics system to handle outbound, inbound, and outbound operations.

Information processing ability includes abilities in information collection, processing, querying, communication, and even business information processing.

How to unload, inspect, palletize, and transport goods to the alleyway entrance of high-rise shelves, and the process of unpacking, merging, picking, handling, and loading goods after being taken out of high-rise shelves.

The connection between operators and the system, human-machine interface operation, information input, handling of non-conforming products during inspection, and operation of automatic transportation lines.

It is necessary to consider the hardware equipment required for automated warehouses, including shelves, stackers, conveyor lines, sorting machines, AGV carts, and sensors, as well as factors such as equipment performance, reliability, applicability, and cost.

It is necessary to consider the software systems required for automated warehouses, including warehouse management systems (WMS), equipment control systems (ECS), communication systems, and visualization systems, as well as the integration and interconnection between various systems.

The above matters need to be communicated with the manufacturer in advance according to their own storage needs, and the various parameters should also meet their own storage requirements.

- Functional requirements: warehousing, outbound, handling, information processing, personnel operation and maintenance, etc.

- Requirements for automation level: manual, semi-automatic, fully automatic, etc.

- Auxiliary requirements: video monitoring, temperature and humidity measurement and control, access control, manual handling of vehicles, etc.

- System scope of work: In order to complete the selection of automated three-dimensional warehouses, both parties must sign a contract, so it is necessary to clarify the scope of work of both parties and the supply scope of the seller.

- Technical equipment: The core of a Sheet Metal Intelligent Warehouse is its technical equipment. Although relying on equipment automation can improve work efficiency, the quality and performance of the equipment need to be considered.

When selecting equipment, it is necessary to have sufficient understanding of the equipment manufacturer and conduct detailed comparison and testing.

- System software: The system software for automated warehouse operations is also very important. System software can automatically control the operation of the entire warehouse, allocate robots, and manage pick-up. Therefore, the quality and performance of automation system software are key factors.

When selecting system software, it is necessary to consider its performance, usability, upgrades, and support to ensure the reliability and stability of the system.

- Logistics configuration: Sheet Metal Intelligent Warehouses are also crucial in terms of logistics configuration. Logistics configuration can be achieved by adding transportation equipment, shelves, forklifts, and other means to complete the completeness and automation of the logistics system.

It is important to note that the purchaser should clarify the specific requirements for the equipment in advance before communicating to ensure the smooth implementation of the plan and its normal use in the later stage.

- When choosing a Sheet Metal Intelligent Warehouse, do not overly pursue the high performance of individual equipment and neglect the overall system performance.

- Building area: Generally speaking, Sheet Metal Intelligent Warehouse have a larger building area. Therefore, when selecting a site, consideration should be given to the surrounding transportation, water and electricity supply, etc., to ensure that there is sufficient land and resources to meet the construction needs. At the same time, it is necessary to plan the height and width of the shelf storage to ensure that enough goods can be stored.

- Environmental protection and energy conservation: It is necessary to consider the environmental protection and energy conservation requirements of automated warehouses, including equipment energy consumption, emissions, and noise, in order to reduce the impact on the environment and lower operating costs.

- Various requirements should be appropriate, and the key is to meet one's own usage requirements. The requirements are too low to meet the usage needs. Excessive requirements may lead to high system costs, reduced reliability, implementation difficulties, inconvenient maintenance, or reduced flexibility.

- Daily maintenance of the system is very important, just like the principle of car maintenance. Therefore, it is necessary to regularly maintain the system to maintain good working condition, extend its service life, and promptly identify potential faults.

- Security and reliability: It is necessary to consider the security and reliability of automated warehouses, including equipment failures, network security, and data security, to avoid losses and risks caused by failures or security issues.

- Maintenance and upkeep: It is necessary to consider the maintenance and upkeep requirements of automated warehouses, including regular inspections, upkeep, and repairs of equipment, to ensure the normal operation and service life of the equipment.

- Standards and regulations: It is necessary to comply with relevant industry standards and regulations to ensure that warehouse design and operation meet safety, health, and environmental requirements.

- Emergency plan: It is necessary to consider the emergency plan of the automated warehouse, including the handling plan and response measures for equipment failures, network security attacks, natural disasters and other emergencies, to ensure the emergency response and recovery ability of the automated warehouse.

Australia Sheet Metal Intelligent Storage System For Sale

Through good procurement and planning, Sheet Metal Intelligent Warehouses can be utilized more efficiently, improving storage efficiency and providing strong support for the development of enterprises.

Click here to know more about intelligent storage system:

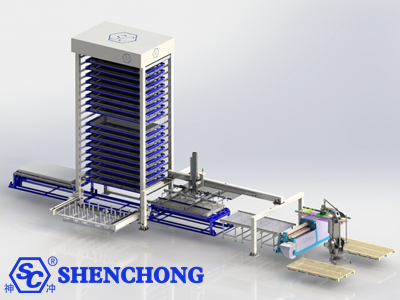

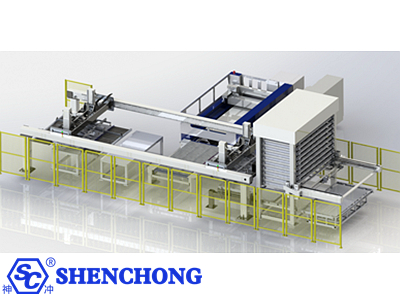

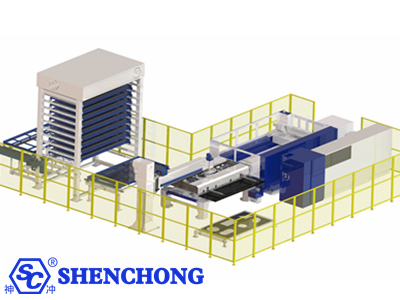

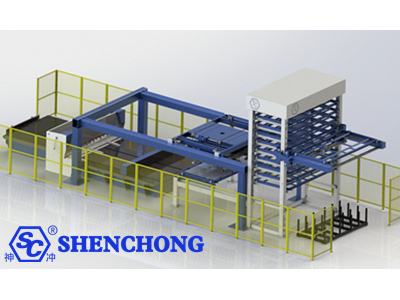

SC Double Row Sheet Metal Storage System