What is laser cleaning? Laser cleaning machine is an efficient and environmentally friendly equipment, widely used in various fields. It mainly uses the high energy and high precision characteristics of laser beam to clean the surface of objects non-contactly. So as to achieve the purpose of removing stains, oil stains, oxides and other impurities.

Laser cleaning is a new and efficient environmentally friendly cleaning technology, which is a new technology based on the interaction effect between laser and matter.

Unlike traditional mechanical cleaning, chemical cleaning and wet cleaning processes, it does not require any CFC organic solvents that damage the ozone layer, is pollution-free, noise-free, harmless to the human body and the environment, and is a "green" cleaning technology. In order to meet the needs of green and sustainable development in the era, laser cleaning equipment came into being and has gradually replaced traditional cleaning processes in many fields.

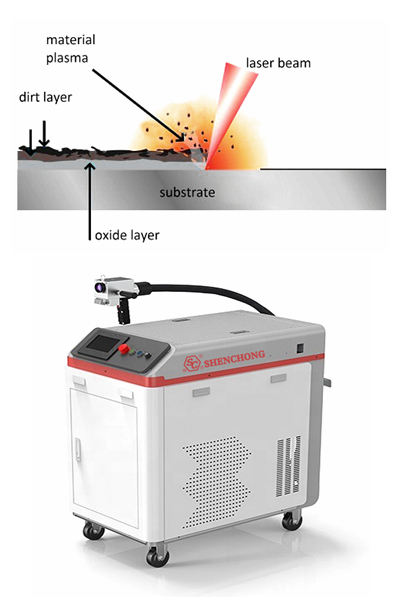

The laser cleaning process depends on the characteristics of the light pulses generated by the laser, and is based on the photophysical reaction caused by the interaction between the high-intensity beam, short-pulse laser and the contamination layer.

Laser cleaning technology refers to the use of high-energy laser beams to irradiate the surface of the workpiece, causing the dirt, rust or coating on the surface to evaporate or peel off instantly, and quickly and effectively remove the surface attachments or surface coatings of the cleaning object, thereby achieving a clean process.

The laser beam is absorbed by the contamination layer on the surface to be treated. The energy density of the laser can be adjusted to make the dirt expand due to heat. When the expansion force of the dirt is greater than the adsorption force of the dirt on the substrate, the dirt will fall off the surface of the object.

The light pulse width must be short enough to avoid heat accumulation that damages the treated surface. The divergence angle of the laser beam is small and the directionality is good. The laser beam can be focused into light spots of different diameters by the focusing system. The absorption of large energy forms a rapidly expanding plasma (highly ionized unstable gas) that produces shock waves.

Each laser pulse removes a certain thickness of the contamination layer. If the contamination layer is thick, multiple pulses are required for cleaning. The number of pulses required to clean the surface depends on the degree of surface contamination.

An important result of the two thresholds is the self-control of cleaning. Light pulses with energy density higher than the first threshold will continue to remove contaminants until they reach the substrate material. However, because their energy density is lower than the damage threshold of the substrate material, the substrate will not be damaged.

Laser cleaning involves both physical and chemical processes. In most cases, physical processes are dominant, accompanied by some chemical reactions.

The main physical processes can be summarized into three categories, including vaporization process, impact process and oscillation process, and the corresponding technologies are wet laser cleaning technology, laser plasma shock wave technology and dry laser cleaning technology.

When high-energy laser irradiates the surface of the material, the surface absorbs the laser energy and converts it into internal energy. The surface temperature rises rapidly to above the vaporization temperature of the material, so that the pollutants are separated from the surface of the material in the form of steam.

Selective vaporization usually occurs when the absorption rate of the surface pollutants to the laser is significantly higher than the absorption rate of the substrate to the laser. A typical application case is the cleaning of dirt on the surface of stone.

When the pollutants are cleaned and the laser is irradiated to the surface of the stone, the absorption is weak and more laser energy is scattered by the surface of the stone. The temperature change on the surface of the stone is small, so the surface of the stone is protected and not damaged.

The impact process is a series of reactions that occur during the action of the laser and the material, and then the shock wave on the surface of the material is formed.

Under the action of the shock wave, the surface pollutants are broken into dust or fragments and peeled off from the surface. There are many mechanisms that cause shock waves, including plasma, steam, and rapid thermal expansion and contraction.

Under the action of short pulses, the material heats up and cools down extremely quickly. Because different materials have different thermal expansion coefficients. Therefore, under the irradiation of short-pulse lasers, the surface contaminants and the substrate will undergo high-frequency thermal expansion and contraction of different degrees, resulting in oscillation, causing the contaminants to peel off from the surface of the material.

In this peeling process, the material may not be vaporized, and plasma may not be generated. Instead, the shear force formed at the interface between the contaminant and the substrate under the oscillation action destroys the bond between the contaminant and the substrate.

Studies have shown that when the incident angle of the laser is slightly increased, the contact between the laser and the interface of the particle contaminant and the substrate can be increased, the threshold of laser cleaning can be reduced, the oscillation effect can be more obvious, and the cleaning efficiency can be higher. However, the incident angle should not be too large. Too large an incident angle will reduce the energy density acting on the surface of the material and weaken the cleaning ability of the laser.

The typical process based on chemical action occurs when using ultraviolet laser to clean organic pollutants, which is called laser ablation.

The wavelength of ultraviolet laser is short and the photon energy is high. For example, KrF excimer laser has a wavelength of 248nm and a photon energy of up to 5 eV, which is 40 times higher than the photon energy of CO2 laser (0.12 eV). Such high photon energy is enough to destroy the molecular bonds of organic matter, causing C-C, C-H, C-O, etc. in organic pollutants to break after absorbing the photon energy of the laser, thereby producing cracking and gasification, and the organic pollutants are thus removed from the surface.

Laser cleaning machine is an efficient, environmentally friendly and energy-saving equipment with a wide range of application prospects. Laser cleaning is used in many industries such as high-speed rail, aerospace, ocean, automobile, mold, track, nuclear power, machinery, sheet metal, electricity, cultural relics, etc. It can clean non-ferrous metals, alloys, wood, stone and other materials, subverting traditional cleaning technologies such as chemical cleaning, mechanical grinding, dry ice cleaning, and ultrasonic cleaning.

The following will introduce the characteristics, applications and advantages of laser cleaning machines in detail.

Laser cleaning equipment is mainly composed of laser and laser cleaning head, control system, chiller and accessories. It can realize intelligent and fast cleaning, with precise range of action and simple operation.

Laser cleaning machine uses laser beam to clean the surface of the object without the use of any chemical agents or mechanical tools. Therefore, it will not cause any damage or scratches to the surface of the object. It does not damage the workpiece, no medium residue, and no secondary pollution.

Laser cleaning machine can completely remove stains, oil stains, oxides and other impurities on the surface of the object, so that the surface of the object can restore its original gloss and texture. The cleaning effect is very good.

Laser cleaning machine is suitable for cleaning the surface of objects of various materials and shapes, including metals, non-metals, planes, curved surfaces, etc.

Laser cleaning machine does not need to use any chemical agents, will not produce any wastewater and exhaust gas, and will not pollute the environment. This is a very environmentally friendly cleaning method. Cleaning waste is mainly solid powder. The waste is small in size, easy to store and recyclable.

Optical fiber transmission allows for long-distance operation. It ensures personnel safety when cleaning hazardous areas. It can be combined with computer numerical control systems or manipulators and robots to achieve automatic cleaning. It improves production efficiency and reduces labor intensity.

Laser cleaning machine adopts non-contact cleaning method, which has fast cleaning speed and high efficiency, and can greatly improve production efficiency.

Laser cleaning machine does not need to use any chemical agents and does not require subsequent treatment, so it can reduce cleaning costs.

Laser cleaning machine is an environmentally friendly cleaning method that does not produce any wastewater and exhaust gas, and does not pollute the environment.

Laser cleaning machine can thoroughly remove stains, oil stains, oxides and other impurities on the surface of objects, restore the original gloss and texture of the surface of objects, and improve the cleaning quality.

At the same time, the current shortcomings of laser cleaning cannot be ignored.

First, the cost of laser cleaning equipment is relatively high. Nowadays, laser cleaning has developed from hundreds of watts to kilowatts, and the purchase cost has also dropped significantly. However, it still maintains a price of tens of thousands of US dollars. Traditional cleaning is very cheap, and dry ice cleaning equipment is as low as a few thousand US dollars.

Secondly, laser cleaning is good at dealing with flat dirt, which is also its limitation. When encountering workpieces with irregular shapes, corners, and narrow spaces, laser cleaning is difficult to work. For example, for the internal cleaning of workpieces similar to the inner wall of a pipe, full immersion pickling is better than laser cleaning.

Finally, although laser cleaning is effective in dealing with rust. However, in actual applications, the dirt components on the surface of production equipment or products are diverse, such as oil stains, semi-solidified solids, etc. For this type of dirt, the key issue is that high-power lasers are most suitable.

At present, the power of laser cleaning can achieve several kilowatts of equipment, but cleaning is not the higher the power, the better. At present, whether high-power beams will damage the surface of workpieces and how to control the degree of damage still needs further research.

After more than ten years of research, the application of laser cleaning has become more extensive. It involves the cleaning of mechanical industry, microelectronics industry and artworks. In addition to the application of laser ultrasonic cleaning in cleaning cultural relics, paint removal and rust removal, microelectronics, etc., it can also be used in many other fields, such as cleaning tire molds, optical material surfaces, some building materials, etc.

When removing esters and mineral oils used for lubrication and corrosion resistance on precision instrument parts, traditional chemical methods are usually used, and chemical cleaning often still has residues.

Laser deesterification can completely remove esters and mineral oils without damaging the surface of parts. The laser causes the explosive gasification of the thin layer of oxide on the surface of the parts to form a shock wave, resulting in the removal of dirt rather than mechanical interaction.

At present, the cleaning of rails before welding is all done by grinding wheels and belts, which causes serious damage to the substrate and residual stress. In addition, a large amount of grinding wheel consumables are consumed every year, which is costly and causes serious dust pollution to the environment.

Laser cleaning can provide high-quality, efficient and green cleaning technology for high-speed railway track laying production. While solving the above problems, the welding defects such as holes and gray spots of seamless rails are eliminated, and the stability and safety of high-speed railway operation are improved.

Before the surface of the aircraft is repainted and maintained, the original old paint needs to be completely removed. Chemical immersion or wiping is the main method of paint removal in the aviation field.

This method will cause a large amount of chemical auxiliary waste, and it is impossible to achieve local repair and paint removal. This process is heavy and harmful to health. Laser cleaning can achieve high-quality removal of paint on the surface of the aircraft skin.

Laser cleaning of cultural relics, crafts and buildings has been widely used. In Europe, people have cleaned various buildings, such as the Martyrs' Cemetery in Poland and the West Executive Palace in London.

Using KrF excimer lasers, lasers with a wavelength of 1.06nm can effectively clean the dirt of stone carvings and other crafts (such as limestone, marble and bones) without damaging the cultural relics themselves.

However, it should be noted that the application effect of laser cleaning technology is very reliable, but not all cultural relics can be cleaned by laser. For example, colorful handicrafts will have different absorbed energies due to different colors absorbing laser light, so the parts with high energy absorption will be damaged.

Laser cleaning has been applied in the field of tattoo cleaning and eyebrow tattooing. In the past, chemical cleaning or further tattoo covering not only failed to completely remove the pigment, but also left scars and even endangered health.

Apply laser to the affected area, use the energy transmitted by the laser to quickly break up the pigment particles, remove the tattoo pigment through skin peeling and cell phagocytosis and other metabolic methods, and the laser cleaning effect is good and does not harm the patient's skin.

The laser cleaning process can remove all organic materials, which has incomparable advantages compared with traditional cleaning technology. The safety and reliability of cleaning have been proven in industrial applications. Laser cleaning is a technology with great development prospects. With further scientific research and industrial practice, it is believed that this technology will be more and more widely used in various fields.

Laser cleaning can be used not only to clean organic pollutants, but also to clean inorganic substances, including metal rust, metal particles, dust, etc. Laser cleaning uses the characteristics of laser beams such as high energy density, controllable direction and strong convergence ability to destroy the binding force between pollutants and the substrate or directly gasify pollutants for decontamination. Reduce the bonding strength between pollutants and the substrate, thereby achieving the effect of cleaning the surface of the workpiece.

Laser cleaning technology has developed rapidly in the past two years. Great progress has been made in the research of laser cleaning process parameters and cleaning mechanism, cleaning objects and application research. However, after a lot of theoretical research, the focus of laser cleaning technology is constantly shifting to application research, and gratifying results have been achieved in application.

Due to the high cost of lasers and their supporting hardware, the application scope of laser cleaning technology is greatly limited, especially in the cleaning of low-cost objects. With the development of science and technology, if the cost of lasers and their hardware continues to decline, the application of this technology in industry will become a reality, and its application scope will also be broadened. As people's awareness of environmental protection continues to increase, laser cleaning machines will be applied and promoted in more fields.

Click here to know other laser machinery: