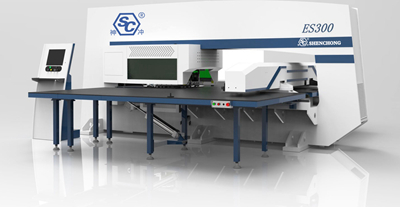

With the continuous development of the manufacturing industry, CNC punching machines have become a common metal processing equipment. Among them, servo CNC turret punch press are widely used in various metal processing fields due to their high efficiency, precision and flexibility. This article will introduce in detail the characteristics, working principle and features of the servo CNC punching machine, which will help readers better understand and know this metal processing equipment.

Servo CNC turret punching machine is a metal processing equipment. It is characterized by using servo motor as the driving source. Compared with traditional hydraulic or pneumatic punching machine, servo CNC punching machine has higher precision, faster speed and better energy saving effect.

In addition, CNC servo turret punch also has the following advantages:

- High precision: the servo motor can achieve precise speed control and positioning, thus ensuring the accuracy of the stamping process.

- High efficiency: due to the use of servo motors, the processing time can be greatly shortened and production efficiency can be improved.

- Good programmability: servo CNC punching machines are generally equipped with CNC systems, which can realize various complex processing operations through programming.

- Energy saving and environmental protection: Servo motors have high energy utilization and low noise, which is conducive to energy-saving and environmentally friendly production.

The servo system of servo CNC turret punch press is mainly composed of servo driver, servo motor and feedback device. The servo driver is the core of the servo system, which can convert the input command into electrical signals and drive the servo motor to move.

The servo motor is an actuator, which can convert electrical signals into mechanical motion. The feedback device is used to detect the position and speed of the motor and feed back this information to the servo driver.

The servo system of CNC turret punch press achieves precise movement and processing through position control. Position control compares the input position command with the actual position detected by the feedback device, and then adjusts the movement of the motor according to the comparison result to achieve the purpose of precise position control.

The servo system can also control the speed of the motor through speed control. Speed control is to compare the input speed command with the actual speed detected by the feedback device, and then adjust the motor current according to the comparison result to achieve the purpose of precise speed control.

In addition to position and speed control, the servo system can also control the output torque of the motor through torque control. Torque control is to compare the input torque command with the actual torque detected by the feedback device, and then adjust the motor current according to the comparison result to achieve the purpose of precise torque control.

The servo type turret CNC punch press is also called "servo type CNC turret punch press". It is faster and more energy-saving. It can perform special processes such as rolling, marking, and lettering. It is suitable for efficient production or small and medium batch processing of sheet metal parts of various varieties.

The use of a servo CNC turret punch machine can not only save manpower and materials, but also improve product quality. Single forming and continuous forming functions: rolling, lettering and marking, shutters, and embossing.

The turret CNC punch press servo type uses a 5-axis fully electric CNC turret punch press, which has higher stamping efficiency and processing accuracy. The key precision parts such as the turret and workbench adopt a casting structure with higher stability.

The turret CNC punch press servo type can punch holes, cut corners, blank, press dimples, roll tendons, type, flanging and even tapping. It requires a special mold, which is expensive and durable.

The turret CNC punch press servo type is widely used in cold stamping processing industries such as screens, lids, chassis cabinets, can production lines, instruments, electric control cabinets, solar water heaters, automobile and bicycle accessories, metal furniture, muffler panels, lamps, battery iron plates, building decorative panels, kitchen equipment, elevator textile machinery, etc. It is very efficient and is often a more economical means for large-scale plate gold.

The CNC turret punch press servo type adopts a servo motor and crankshaft connecting rod direct drive structure. The structure is mature and reliable. The special installation process effectively eliminates the mechanical clearance, making it have the characteristics of high transmission accuracy, low noise, long life, and no need for frequent maintenance.

The use of a servo closed-loop motor can effectively improve the forming effect. The unique internal energy-saving design can effectively recycle the braking energy generated during actual use and reuse it for stamping action, which greatly reduces the comprehensive energy consumption of the machine and effectively reduces the cost of using the machine.

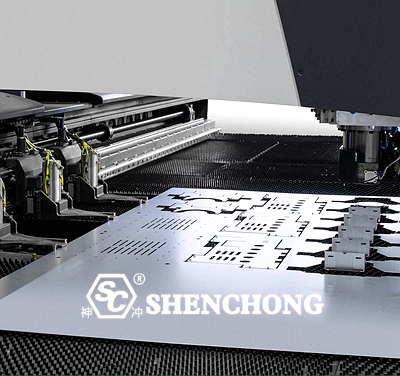

The turret CNC punch press servo type can punch various shapes of large round holes, square holes, waist-shaped holes, curved contours, and can also be punched with small punching dies. It can also perform special processes such as louvers, shallow drawing, countersinking, flanging holes, reinforcing ribs, punching, etc.

The turret CNC punch press servo type punch head adopts servo control, accurately controls positioning, and the bottom dead point positioning accuracy reaches 0.01mm, which can achieve efficient and precise rolling forming, energy saving, environmental protection, low energy consumption, and low noise.

The feedback device of the servo system can detect the position and speed of the motor in real time, and make adjustments by comparing the command and the actual value, thereby achieving high-precision processing and control.

The servo drive of the servo system has the characteristics of fast response, which can respond to the command in a short time, thereby speeding up the processing speed of the CNC punch press.

The servo system can adapt to different working environments and processing requirements, and can implement different control strategies by adjusting parameters to meet different processing needs.

- Unique design of high-strength body, stable performance.

- The main punching power adopts a fully electric servo motor, which is efficient and energy-saving.

- It can realize punching, forming, rolling, lettering and other processes.

- Mechanical transmission and electrical and pneumatic components are all imported brands.

The servo CNC turret punch press uses a drive system to control multiple punches on the turret to impact and complete the processing and forming of metal materials.

The servo CNC turret punch press can complete the cutting, punching and other tasks of workpieces of many different shapes and sizes. Equipped with a turret with multiple workstations, different types of punches are installed on each workstation to achieve punching operations of various shapes and sizes.

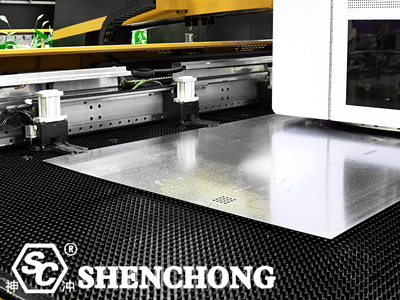

The servo CNC turret punch press has an ultra-wide bed with large guide rail spacing, a large machine span, better horizontality and support, which fully guarantees the accuracy of processing large plates and is more balanced under high-speed feeding. The brush auxiliary platform is integrated with the main platform, and the auxiliary platform can move back and forth with the plate, reducing the friction between the plate and the brush platform by 30%.

The servo system can control the positioning of the punch on the turret between each work position to ensure the accuracy and consistency of processing.

The clamp of the servo CNC turret punch press adopts a pneumatic full-floating clamp. The up and down floating can reduce the deformation of the plate. The long slide plate has good rigidity and the clamp is easy to move. The servo CNC turret punch press has a self-protection function, which makes the processing dead zone.

The AC servo motor of the servo CNC turret punch press runs smoothly and does not vibrate even at low speed. The AC servo system has a resonance suppression function, which can cover the lack of rigidity of the machine, and the system has a frequency resolution function (FFT) inside, which can detect the resonance point of the machine and facilitate system adjustment.

The servo CNC turret punch press has the functions of knocking holes, stretching, shutters, trimming and corner cutting, and engraving and typing.

Servo CNC turret punch presses are widely used in metal processing industries such as power complete sets of equipment, chassis cabinets, curtain wall decoration, household appliances, elevators, fire doors, kitchen equipment, heavy machinery, and ships.

The servo system of the CNC punch press is the core part of the CNC punching machine, which can achieve high-precision processing and control. The composition and working principle of the servo system are the key factors to achieve high-precision processing. By understanding the servo system and optimizing the control strategy, the processing quality and efficiency of the CNC punch press can be improved.

Related information about punching machine:

CNC Punching Machine Guide: Use, Featues And Classification

CNC Turret Punching Machine: Force Calculation And Molds Clearance