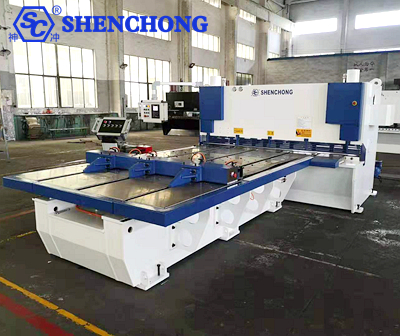

Auto feeding table shearing machine is a common metal processing equipment, which has the advantages of high efficiency, accuracy, safety, etc. It is widely used in construction, manufacturing, sheet metal processing and other fields.

Below is the purchase guide of auto front feeding shearing machine, which will be introduced in detail based on the characteristics, functions, advantages, usage precautions, and application areas of the automatic front feeding and shearing machine.

The traditional working method of a shearing machine is usually to cut the board and the worker sends the board and then repeatedly operates it. If the size of the cut board changes, the shearing machine operator needs to adjust the tooling separately to obtain the desired size and continue processing, resulting in relatively low work efficiency.

The situation is very different when using a CNC automatic front feeding table shearing machine. As long as the desired sheet size is input into the CNC shearing front feeding machine control system, the sheet will be automatically fed, cutting out qualified sheet sizes without the need for tedious and repetitive adjustment of fixtures, greatly improving work efficiency.

During the feeding process of the CNC auto front feeding shear machine, there is no need for workers to repeatedly push the plate or adjust the tooling marking, etc.

With just one press of the start button by the staff, the automatic feeding and shearing machine can complete the entire sheet metal, making it very easy for the CNC feeding machine staff to work before cutting.

The machining accuracy of the CNC automatic front feeding machine is ± 0.20mm, and there will be no dimensional errors caused by old-fashioned shearing machines due to positioning, marking, or negligence of workers.

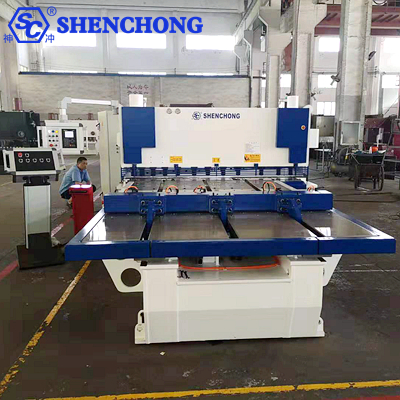

The auto front feeding gate type shearing machine has a dual action function of the upper knife beam and the lower hydraulic pad. The working pressure stroke can be adjusted according to the process requirements within the specified range, and the operation is simple. It is controlled centrally by buttons. There are three operating modes: adjustment, manual, and semi-automatic.

The front feeding table of the auto shearing machine adopts a motorized back gauge device and an electronic counter, which facilitates the adjustment of the back gauge position. The overall welded frame structure was used and subjected to vibration aging treatment. The machine tool has good rigidity, high accuracy, and good accuracy retention. The knife beam is made of steel structural components, which move up and down along the roller under the action of the oil cylinder to achieve cutting action. The front feeding table frame is made of steel structural components, which have been tempered to eliminate internal stress, have strong rigidity, and good stability.

The front feeding table adopts imported precision ball screw drive, linear guide rail guidance, and digital AC servo motor drive. Accurate positioning, fast and stable operation, the front feeding table is arranged with steel balls and brushes alternately. The positioning speed of the three-axis CNC motor can be adjusted arbitrarily, thereby improving work efficiency.

The parameter adjustment function is set within the system, and the reference points of the two axes can be modified arbitrarily to adjust the positioning value of the CNC system. The system is equipped with an automatic retreat function, which can make the feeding frame move away in a timely manner during the cutting process, avoiding friction between the blade and the plate material during the cutting process. Every time the machine is powered on or off, the two axes controlled by the CNC system can automatically find reference points when restarted, ensuring repeated positioning accuracy.

The parameters of the CNC shearing and feeding machine are constant, and the quality of the sheets cut by the automatic feeding shearing machine is less affected by human factors. The requirement for worker operation skills has been reduced, so the quality of shearing is stable.

When using automated feeding and shearing, workers only assist in loading and unloading the boards. By inputting the cutting size through the CNC system interface, operators can transition from tedious physical labor to a combination of programming and operation modes. Increased work enjoyment and increased efficiency more significantly.

The pace of automated production is fixed, so arranging production plans is very clear. WUXI SHENCHONG front-feeding shearing machine front feeding stroke, cutting angle, blade gap, and memory cutting times.

The automatic retreat function of the system avoids friction between the sheet metal and the blade. The system can automatically calculate the cutting stroke based on the width of the sheet metal, saving cutting time to the maximum extent. The CNC system has 100 programs in memory, and each program can be programmed with 25 work steps.

There are many factors that affect the accuracy of the shearing machine, such as the type of equipment used, the skill of the operator, the thickness of the material being cut, and so on.

The precision of WUXI SHENCHONG auto feeding table shearing machine can reach 0.03mm/m with high energy, and the cut sheet metal has no burrs, which can meet the requirements of laser welding process.

- Operators must undergo professional training and be familiar with the structure and operating procedures of the equipment before they can operate on duty.

- Before operation, carefully inspect all parts of the equipment, such as tools, molds, electrical components, etc., to ensure that the equipment is in a safe state.

- During operation, it is necessary to strictly follow the operating procedures and not violate any rules. At the same time, it is necessary to constantly observe the operation of the equipment. If any abnormal situation is found, it should be stopped immediately for inspection.

- After the operation is completed, carefully clean the equipment and keep it clean and in good condition. At the same time, it is necessary to do a good job in equipment maintenance and upkeep to extend the service life of the equipment.

The auto feeding table shearing machine is widely used in various metal processing operations in the construction industry, such as cutting and stamping various metal materials, such as steel plates, stainless steel plates, etc.

The front feeding shearing machine is suitable for metal processing operations in various manufacturing industries, such as automotive manufacturing, mechanical manufacturing, etc. In these industries, the front feeding shearing machine can quickly and accurately complete the cutting and stamping operations of various metal materials.

The front feeding shearing machine is also widely used in the sheet metal processing field. It can efficiently complete the cutting and stamping work of various sheet metal parts, such as making various shapes of metal boxes, metal plates, etc.

In short, the auto feeding table shearing machine is a powerful, easy to operate, and widely used metal processing equipment. Through reasonable use and maintenance, it can play an important role in improving production efficiency, reducing costs, and improving product quality for enterprises. At the same time, it is also necessary to pay attention to complying with relevant regulations and operating procedures during use to ensure the safety and stability of the equipment.

Know more about front feeding shears, click here:

Introduction Of Front Feeding Guillotine Shear Explained

Advantages and Differences: Why Choose Front-Feeding Guillotine Shear?