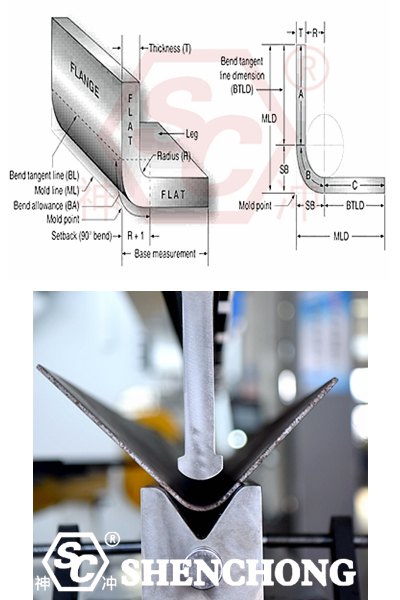

In CNC press brake machine sheet metal bending processing, sheet metal setback, bend allowance, bend deduction and bend radius are four important parameters that are closely related. Together, they affect the size and processing accuracy of the final product. Understanding the relationship between them is essential for the precise design of sheet metal processing. Although they look similar, they have different meanings and calculation methods.

Sheet metal setback (or sheet metal springback) refers to the shape and size changes of metal materials after processing due to the elastic properties of the material during sheet metal processing.

Specifically, sheet metal setback refers to the elastic rebound of metal materials after the force is removed after stamping, bending, stretching and other operations, resulting in changes in the shape or angle of the workpiece. It usually manifests as a rebound of the bending angle or size. This rebound phenomenon usually occurs in the elastic deformation zone.

Instead of the plastic deformation zone, sheet metal setback is a common problem in sheet metal processing, especially in the bending and forming process. In order to compensate for the springback effect, designers and manufacturing process personnel need to consider factors such as material characteristics, thickness, bending radius, bending angle, and make corresponding adjustments, such as overbending, prestressing or subsequent finishing operations.

The factors of sheet metal setback include material characteristics, processing methods, material thickness, workpiece size and shape. Usually in the design stage, simulation analysis and experimental data are used to predict and compensate for the springback effect to ensure the accuracy of the final product.

There are many factors that affect sheet metal setback (springback), mainly involving material properties, process parameters, tool design and other aspects. The following are some of the main influencing factors:

The higher the elastic modulus of the material, the stronger the material's tendency to rebound, because harder materials are less likely to undergo plastic deformation under external forces, and thus the elastic rebound phenomenon is more obvious.

Yield strength is the critical stress value for plastic deformation of the material. Higher yield strength means that it is more difficult for the material to enter the plastic region during processing, and the rebound phenomenon may be more serious.

Materials with higher hardness usually rebound more, because hard materials are more difficult to bend when subjected to force, and the elastic rebound is more obvious.

The thicker the material, the greater the rebound amplitude is usually. Because thicker materials require greater force to undergo plastic deformation, and after the force is removed, the elastic recovery of thicker materials will also be more significant.

Some metal materials (such as stainless steel and aluminum alloy) are prone to work hardening during processing, which will affect the elasticity and plasticity of the material and thus affect the springback.

In the process of sheet metal bending, the larger the bending angle, the greater the degree of springback. When bending, the stress distribution of the material is different, and bending at a larger angle is prone to produce greater elastic recovery.

If the mold is not designed properly, such as a small bending radius, it may cause excessive deformation of the material, thereby aggravating the setback.

The bending radius has a great influence on springback. A smaller bending radius will lead to more stress concentration, and the material is prone to springback. A larger bending radius helps to reduce the amplitude of springback because the stress distribution is more uniform and the degree of plastic deformation is greater.

For example, parameters such as pressure and speed during bending will also affect the springback of the material. High-pressure and high-speed bending processing may reduce the amplitude of springback because the material undergoes more plastic deformation under greater force.

In some cases, using pre-stretching technology to treat the material can improve the plasticity of the material and reduce the amplitude of springback.

The accuracy and fit of the mold directly affect the accuracy of the bending. If the mold is not accurate or does not match, it may cause uneven local deformation of the material during processing, thereby exacerbating the springback.

Whether the structural design of the mold is reasonable will also affect the springback. For example, using appropriate dead zone and appropriate pressure can help reduce springback.

For large-sized workpieces or workpieces with complex shapes, it is usually more difficult to control springback. Especially for longer workpieces, the amplitude of springback may be relatively large.

If there are multiple bends or irregularly shaped workpieces, special considerations may be required to control springback, which usually requires more sophisticated process control.

At high temperatures, the plasticity of the material will increase and the springback phenomenon may be reduced. Many sheet metal processing processes, such as hot bending and hot forming, are carried out at a certain temperature to reduce springback.

After a series of processing operations, the residual stress of the material may affect the springback. If the stress of the workpiece is not effectively released, it may cause setback.

Materials with smooth surfaces are easier to bend, while materials with rough surfaces or coatings may increase friction, resulting in uneven force transmission during processing, which in turn affects the degree of springback.

In actual production, the experience of process personnel is also very important. Skilled technicians can better control springback by adjusting process parameters, selecting appropriate materials, and mold design.

In order to control the setback of sheet metal, simulation analysis (such as finite element analysis) is usually used in the design stage to predict the degree of springback and perform compensation design. In addition, in actual production, the springback effect can also be reduced by adjusting the processing technology, selecting appropriate materials, and accurately designing molds.

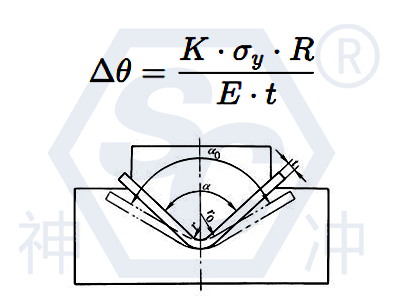

The setback (springback) of sheet metal refers to the change in shape or angle caused by the rebound of the material after the external force is removed during the bending or forming process due to the elastic properties of the material. In order to accurately predict and control the springback, it is usually necessary to calculate the springback according to some specific formulas and methods. The following are the basic steps and formulas for calculating the setback of sheet metal.

The springback (Δθ) refers to the change in angle of the metal sheet due to elastic rebound after the external force is removed after bending. The calculation of the springback involves factors such as the elastic modulus, yield strength, thickness, and bending radius of the material.

Usually, the springback can be calculated by the following formula:

Δθ=(K·σy·R)/ E·t

- Δθ: Springback angle (unit: degree or radian)

- K: Springback coefficient, depends on the material and bending method, usually between 0.1 and 0.2 (determined according to experimental data)

- σy: Yield strength of material (unit: Pa or N/m²)

- R: Bending radius (unit: mm)

- E: Elastic modulus of material (unit: N/mm² or Pa)

- t: Material thickness (unit: mm)

This formula is applicable to small angle bending. The springback is related to the yield strength, elastic modulus, bending radius and material thickness of the material.

Click here to know more about: Bending Springback of Sheet Metal Parts [Causes & Measures]

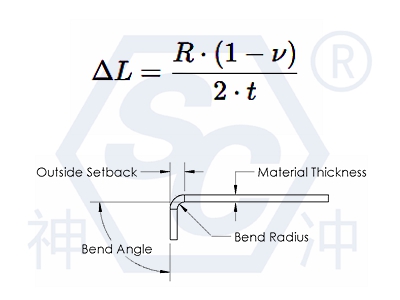

There are also some empirical formulas for estimating springback of sheet metal, for example:

ΔL=R·(1−ν)/2·t

- ΔL: change in length of springback (unit: mm)

- R: bending radius (unit: mm)

- ν: Poisson's ratio (ratio of transverse strain to longitudinal strain of the material)

- t: material thickness (unit: mm)

This formula is applicable to the change in material size during the bending process and is usually used to calculate the change in the shape of the workpiece after bending.

In practical applications, designers usually take certain compensation methods to reduce the springback effect. These methods include:

By setting the bending angle larger than the final target angle during design, the expected angle is obtained after springback.

Choosing a suitable bending radius can help reduce the springback. A larger bending radius usually reduces springback.

Adjust the springback amount through experimental data according to the springback coefficient of different materials.

How to Guide: Press Brake Bending Unfolded Length Calculation [Y and K factors ]

In the design stage, predict springback through computer simulation (such as finite element analysis) and perform compensation design.

During the sheet metal processing process, the material may undergo work hardening (work hardening), which will cause the material's springback to change. Therefore, this effect needs to be considered when calculating the springback.

The temperature of the material will also affect its springback behavior. During heat treatment or high-temperature bending, the elastic modulus of the material decreases and the springback may decrease.

- Material yield strength σy=250 MPa

- Bending radius R=10 mm

- Elastic modulus E=210000 MPa

- Material thickness t=2 mm

- Rebound coefficient K=0.15K (assumed value)

Δθ=(0.15×250×10)/(210000×2)=3750/420000=0.00893rad

Convert radians to degrees:

Δθ=0.00893×(180/π)≈0.511∘

This rebound angle means that after bending, the material rebounds by about 0.511 degrees after the external force is removed.

The calculation of sheet metal setback is a complex process that requires consideration of multiple factors, such as material properties, bending radius, process parameters, etc. By accurately calculating the springback amount and making appropriate compensation designs, the springback problem in sheet metal processing can be effectively controlled to ensure that the size and shape of the final workpiece meet the requirements. In actual operation, the springback amount can be accurately predicted through experimental data, simulation analysis and empirical formulas.

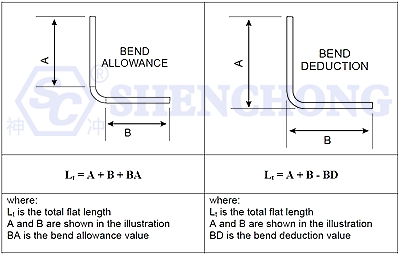

Bend allowance and bend deduction are two concepts related to sheet metal bending, which are usually used in metal processing and sheet metal design.

- Bend allowance refers to the extra length that needs to be reserved for the sheet when bending the sheet to ensure that the shape after bending meets the requirements. This is because during the bending process, the inner and outer surfaces of the sheet will stretch or compress, and the bend allowance is used to compensate for this change.

- Usually, the size of the bend allowance is related to the thickness, bend angle and bend radius of the material.

What is Press Brake Bend Allowance? [ Formula for Beginners]

The bend allowance table is a tool used in sheet metal design and processing to help determine how much extra length (bend allowance) needs to be reserved when bending sheet metal to ensure that the size of the sheet after bending meets the design requirements. The bend allowance table is calculated based on factors such as material thickness, bend radius and bend angle.

- Material thickness (T): that is, the thickness of the sheet, usually in millimeters (mm).

- Bending radius (R): The inner bending radius when bending, usually in millimeters.

- Bending angle (θ): The angle of the sheet bending, usually in degrees (°).

- Bending allowance (BA): Refers to the additional length that needs to be added during design, usually in millimeters (mm).

The calculation formula of the bending allowance table is:

BA=(θ/360)×2π(R+K)

Where:

BA = bending allowance

θ = bending angle (degrees)

R = bending radius

K= material thickness coefficient, usually a certain proportion of the material thickness (T), usually between 0.5 and 1.

Material Thickness(mm) | Bending Radius(R) | Bending Angle(°) | Bend Allowance(BA,mm) |

1 | 2 | 90 | 3.14 |

1 | 3 | 90 | 4.71 |

2 | 4 | 90 | 6.28 |

3 | 6 | 90 | 9.42 |

4 | 8 | 90 | 12.57 |

5 | 10 | 90 | 15.71 |

6 | 12 | 90 | 18.85 |

- The effect of bending angle on allowance: The larger the bending angle, the larger the bending allowance, so more material length needs to be reserved.

- The relationship between bending radius and material thickness: A smaller bending radius will cause greater material deformation, so a larger bending allowance may be required; while a larger bending radius may require a smaller allowance.

- Material type: Different materials (such as stainless steel, aluminum, copper, etc.) have different physical properties, and the allowance may need to be adjusted according to the specific material.

- Accuracy: The bending allowance table provides a reference value, and in actual production, it may also need to be fine-tuned according to the specific bending machine, process requirements and other factors.

- Determine material thickness: Determine the material thickness according to the design drawing.

- Select the bending radius: Select the appropriate bending radius according to the design requirements and processing technology.

- Determine the bending angle: Determine the bending angle, which is usually 90°, but it may also be adjusted according to actual conditions.

- Find the bending allowance: Use the bending allowance table to find or calculate the corresponding bending allowance.

- Adjust the cutting length: Add the bending allowance to the length of the initial sheet to ensure accurate dimensions after bending.

The bending allowance table provides sheet metal designers and processors with a quick and easy tool to help accurately calculate the sheet length required for bending and avoid dimensional errors caused by bending deformation.

- The bend deduction is the part that needs to be subtracted from the total length of the sheet after bending to compensate for the elongation of the sheet during the bending process. It is a correction factor when calculating the length of the finished product.

- The bend deduction is usually smaller than the bend allowance because it takes into account the actual effect of sheet deformation after bending, especially the elongation and compression of the inner and outer surfaces.

- When calculating the bend deduction, factors such as material thickness, bend radius and angle are usually considered.

In actual operation, the bend allowance and bend deduction are used to calculate the original length of the sheet to ensure that the size of the finished product meets the design requirements. In sheet metal design and engineering drawings, these values are often found through standard tables or professional software.

The bend deduction table is a commonly used tool in sheet metal design and processing to determine the part that needs to be deducted from the original length of the sheet when bending sheet metal. This deduction is used to correct the deformation of the sheet caused by bending to ensure that the final size after bending meets the design requirements.

Bend deduction is the length subtracted from the total length of the sheet during the bending process, mainly because bending causes deformation of the inner and outer surfaces of the material, usually the inner side is compressed and the outer side is stretched. Bend deduction is closely related to factors such as bending radius, sheet thickness and bending angle.

The common calculation formula for bend deduction is:

Bend Deduction (BD) = 2 × (R + K) × θ / 360 × π − 2 × K

Where:

R = bend radius (inside bending radius)

K = material thickness (sheet thickness)

θ = bend angle (unit: degree)

π = pi (about 3.1416)

Material Thickness(mm) | Bending Radius(R) | Bending Angle(°) | Bend allowance(BA,mm) |

1 | 2 | 90 | 2.45 |

1 | 3 | 90 | 3.68 |

2 | 4 | 90 | 4.90 |

3 | 5 | 90 | 6.13 |

4 | 6 | 90 | 7.36 |

5 | 7 | 90 | 8.58 |

6 | 8 | 90 | 9.81 |

2 | 3 | 60 | 3.55 |

2 | 4 | 60 | 4.70 |

- Effect of bend angle on deduction: The larger the bend angle, the larger the bend deduction is usually. The larger the bend angle, the more obvious the deformation of the plate, so more deduction is needed.

- Effect of bend radius on deduction: The larger the bend radius, the smaller the deformation of the plate when bending, so the deduction is relatively small. A smaller bend radius will cause greater deformation, so more deduction is needed.

- Effect of material thickness: The thicker the material, the more obvious the deformation when bending, and the deduction will increase accordingly. Thin plate materials usually have less deduction.

- Determine material thickness: Determine the material thickness according to the design drawing or material selection table.

- Select bend radius: Determine the bend radius according to design requirements or process requirements. Make sure that the selected radius is within the process range.

- Determine the bend angle: Select the bend angle according to the actual situation, usually 90°, but it can also be other angles.

- Find the bend deduction: Find the corresponding deduction in the bend deduction table, or use the calculation formula to calculate it yourself.

- Adjust the cutting length: Subtract the bend deduction from the total length of the plate to get the accurate length after bending.

- The difference between bend allowance and bend allowance: bend allowance is to lengthen the length of the sheet to account for the deformation of the material during the bending process, while bend allowance is to compensate for the elongation and compression of the material and is the part that needs to be subtracted from the total length of the sheet.

- Standards and experience: Different factories, different equipment and different material types may affect the final bend allowance. When using the bend allowance table, it is best to fine-tune it in combination with actual processing experience and standards.

The bend allowance table is one of the indispensable tools in sheet metal processing. By accurately calculating and using the bend allowance, it can ensure that the parts after bending meet the design requirements, reduce processing errors and improve production efficiency.

- The bending allowance is used to compensate for the deformation of the material during the bending process, and the length of the plate needs to be lengthened.

- The bending deduction is used to correct the size of the plate after bending, usually the subtracted part.

The bending radius of sheet metal refers to the inner bending radius of the bent part during the sheet metal bending process. It is an important parameter in the bending process, which directly affects the bending quality and the stress distribution of the sheet metal material.

The selection of the bending radius of sheet metal is determined by the following factors:

In general, the bending radius should be at least equal to the thickness of the material. Thinner materials can usually use a smaller bending radius, while thicker materials require a larger bending radius.

There is usually a rule of thumb: for common sheet metal materials, the bending radius should be at least 1 to 1.5 times the material thickness.

Different materials have different plasticity, which affects the size of their bending radius. For example, brittle materials (such as aluminum alloys) are prone to cracking when bent, so a larger bending radius is required; while softer materials (such as stainless steel) can use a smaller bending radius.

In general, the bending radius of steel can be set to 1-2 times the material thickness, while aluminum may require a larger radius.

At a larger bending angle (close to 90 degrees), a smaller bending radius may cause cracks or deformation of the material, so the size of the bending angle will be considered when designing to select the appropriate bending radius.

The capabilities and type of the bending machine will also affect the minimum bending radius that can be used. Some high-precision bending equipment can achieve a smaller bending radius, while some traditional equipment may have restrictions on the minimum radius.、

Relationship: Press Brake Radius, Thickness and V Die

- Thin plate (≤1mm): The bending radius is usually 1 times the thickness of the plate.

- Ordinary thick plate (1mm~6mm): The bending radius is usually 1.5 times the thickness of the plate.

- Thick plate (>6mm): The bending radius is usually 2 times or more the thickness of the plate.

- Small bending radius (such as microbending, V-bending): If a very small bending radius is required, you may need to consider using other processes such as rolling, laser or water jet to avoid material cracks.

- Large bending radius: For some special requirements (such as appearance requirements, bending at a larger angle), a larger bending radius can be used.

In short, the choice of bending radius needs to be comprehensively considered based on the specific material, thickness, bending angle and production process.

In sheet metal bending, sheet metal setback, bending allowance, bending deduction and bending radius are four important parameters that are closely related. They jointly affect the size and processing accuracy of the final product. Understanding the relationship between them is essential for the precise design of sheet metal processing.

Sheet metal setback refers to the change in material length due to the elongation and compression of the inner and outer surfaces of the material during the bending process. Specifically, the bending process causes the inner side of the sheet to be compressed and the outer side to be stretched, so the bent part of the sheet metal will setback.

The amount of setback is usually small and is closely related to the thickness, bending radius and bending angle of the material. The setback amount is the change in length of the material caused by the stretching and compression effects during the bending process.

Bend allowance refers to the additional length that needs to be reserved on the original length of the sheet in order to make the finished product size correct after bending. The size of this allowance is mainly determined by the bending radius, material thickness and bending angle.

The function of the bending allowance is to compensate for the deformation of the inner and outer surfaces during the bending process. When bending, the material will stretch and compress in the bending area, so additional material length is required during design to ensure that the finished product meets the required size.

Bend deduction refers to the length that needs to be deducted from the original length of the sheet to compensate for the elongation or compression of the material during the bending process. The setback is to make the final bending size consistent with the design.

The setback is usually smaller than the bending allowance because the setback takes into account the actual change in size after bending (including compression and stretching of the inner and outer surfaces).

When calculating the bend deduction, factors such as the bending radius, material thickness and bending angle are taken into account.

The bending radius refers to the radius on the inside of the bending part during the bending process. It is a key factor in determining the degree of material deformation. The smaller the bending radius, the greater the deformation of the inner and outer surfaces of the material.

The bending radius is closely related to the material thickness. A smaller bending radius will result in higher internal stress, so when designing, it is usually necessary to select a suitable bending radius based on the type, thickness and processing equipment capacity of the material.

Too small a bending radius may cause cracks or breakage in the material, so a reasonable bending radius needs to be selected according to the process requirements.

- The larger the bending radius, the smaller the bending allowance is usually. This is because the larger the bending radius, the smaller the tensile and compressive deformation of the inner and outer surfaces of the material, so the impact on the length is also smaller.

- Under the same material thickness and bending angle, a larger bending radius makes the value of the bending allowance smaller.

- The larger the bending radius, the smaller the bending deduction is usually. Similar to the bending allowance, a larger bending radius reduces the deformation of the material, so the setback is also reduced accordingly.

- When the bending angle and material thickness are constant, a larger bending radius means less setback.

- When the material thickness increases, both the bending allowance and the bending deduction increase. This is because thicker materials deform more significantly when bent, resulting in more allowance required to compensate for the deformation.

- Thinner materials require less allowance when bending and have less setback.

Suppose there is an aluminum plate with a thickness of 2 mm, a bending radius of 4 mm, and a bending angle of 90°, to calculate the bending allowance and setback.

BA=(90/360)×2π(4+2)=4.71mm

BD=2×(4+2)×(90/360)×π−2×2=3.77mm

- Bending allowance: The extra length that needs to be reserved during design to compensate for deformation during bending.

- Bending deduction: The part deducted from the original sheet length after bending to ensure that the size after bending meets the requirements.

- Sheet metal setback: The deformation (elongation and compression) of the inner and outer surfaces of the material during the bending process causes the size of the sheet to change.

- Bending radius: The inner bending radius during the bending process directly affects the size of the bending allowance and setback.

Understanding these parameters and the relationships between them helps to design and produce sheet metal parts more accurately, reduce processing errors, and ensure that the product dimensions meet design requirements.