When working with metal welding, understanding the fundamental properties of the materials being welded is crucial for achieving strong, durable, and reliable welds. The performance and quality of a weld can be significantly influenced by the physical, mechanical, and thermal properties of the metal. Here are some key metal welding properties you need to know.

The metal welding properties refers to the ability of metal materials to obtain excellent welding joints under certain welding processes, including welding methods, welding materials, welding specifications, and welding structural forms. A metal is considered to have good welding performance if it can obtain excellent welding joints using more common and simple welding processes. The welding performance of metal materials is generally divided into two aspects: process welding performance and usage welding performance.

It refers to the ability to obtain excellent and defect free welding joints under certain welding process conditions. It is not an inherent property of metals, but an evaluation based on a certain welding method and specific process measures adopted. So the process welding properties of metal materials is closely related to the welding process.

It refers to the degree to which the welded joint or the entire structure meets the specified performance requirements of the product technical specifications. The performance depends on the working conditions of the welded structure and the technical requirements proposed in the design.

It usually includes mechanical properties, low-temperature toughness, brittle fracture resistance, high-temperature creep, fatigue performance, endurance strength, corrosion resistance, and wear resistance. For example, commonly used S30403 and S31603 stainless steels have excellent corrosion resistance, while 16MnDR and 09MnNiDR low-temperature steels also have good low-temperature toughness resistance.

Definition: The temperature at which a metal changes from solid to liquid.

Importance: When welding, the metal needs to be heated above its melting point. Metals with lower melting points (such as aluminum) are easier to melt during welding, while metals with higher melting points (such as steel) require higher temperatures.

Definition: The ability of a metal to conduct heat.

Importance: Metals with high thermal conductivity (such as copper and aluminum) will quickly disperse heat in the welding area, which may result in a small heat-affected zone (HAZ) and difficulty in welding through. Metals with low thermal conductivity (such as steel) are more likely to concentrate heat and are suitable for high-temperature welding.

Definition: The degree to which a metal expands during heating.

Importance: Metals with larger thermal expansion coefficients (such as aluminum) are prone to larger dimensional changes during welding, resulting in welding deformation or cracks. Metals with smaller thermal expansion coefficients (such as steel) are more stable.

Definition: The tensile strength and resistance to surface indentation of a metal.

Importance: Metals with higher strength and hardness (such as stainless steel and high-strength steel) require higher heat input and precise control when welding to prevent cracking or hardening.

Definition: Ductility refers to the ability of a metal to deform when stretched, and toughness refers to the ability of a metal to resist cracking.

Importance: Metals with poor ductility or low toughness (such as cast iron) are prone to cracking during welding, while metals with good toughness (such as low carbon steel) are more suitable for welding operations.

Definition: Whether a metal material is prone to defects (such as pores, cracks, etc.) during welding.

Importance: Metals with good weldability (such as low carbon steel) are easy to weld and have fewer defects; metals with poor weldability (such as cast iron and some high-alloy steels) may require special treatment or welding methods.

Definition: Other elements added to alloys, such as nickel, chromium, molybdenum, etc.

Importance: Alloying elements improve the corrosion resistance, strength and high-temperature performance of metals, but may also affect weldability. For example, nickel increases the strength of stainless steel, but it may also cause hot cracking during welding.

Definition: The ability of a metal to resist corrosion, especially its tolerance to oxidizing, acidic environments.

Importance: Alloy metals such as stainless steel have excellent corrosion resistance and are suitable for marine or chemical environments, while carbon steel is prone to rust and requires additional protection.

Definition: Stress caused by uneven local heating and cooling during welding may cause deformation or cracking of welded parts.

Importance: During welding, the thermal expansion and cooling contraction of the metal will cause residual stress in the weld joint and surrounding areas, affecting the stability of the weld. For deformation-sensitive metals (such as aluminum), special attention should be paid to controlling heat input.

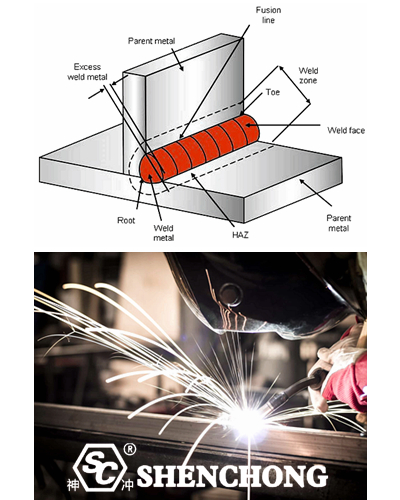

Definition: The area where the parent material is not melted during welding but undergoes microstructural changes due to high temperature.

Importance: The properties of the heat-affected zone will be degraded by excessively high welding temperatures, such as increased hardness or reduced ductility, resulting in cracks or other defects in the weld joint.

Definition: Internal stress of metal caused by heating and cooling during welding.

Importance: Excessive welding residual stress may cause metal warping, cracking or later fatigue damage, especially in high-strength alloy steel or aluminum alloy welding.

Definition: Some metals (such as aluminum alloys and titanium alloys) have special physical and chemical properties.

Importance: For example, aluminum alloys have good weldability, but oxide films are easily formed on their surfaces, which affects the welding quality. Titanium alloys need to be welded in a protective gas environment to prevent oxidation.

Metal Sheet Laser Welding Parameters & Methods

Materials include base metal and welding materials. The main factors determining the welding properties of the base material under the same welding conditions are its physical properties and chemical composition.

In terms of physical properties, factors such as the melting point, thermal conductivity, coefficient of linear expansion, density, and thermal capacity of metals all affect processes such as thermal cycling, melting, crystallization, and phase transformation, thereby affecting welding properties.

Materials with low thermal conductivity, such as stainless steel, have a large temperature gradient during welding, high residual stress, and large deformation,. Moreover, due to the long residence time at high temperatures, the grain size in the heat affected zone grows, which is detrimental to the joint performance. Austenitic stainless steel has a high coefficient of linear expansion, and the deformation and stress of the joint are relatively severe.

In terms of chemical composition, the carbon element has the greatest impact, which means that the amount of carbon in a metal determines its welding properties. Most of the other alloying elements in steel are also not conducive to welding, but their impact is generally much smaller than that of carbon.

As the carbon content in steel increases, the tendency to harden increases, while plasticity decreases, making it prone to welding cracks. Usually, the sensitivity of metal materials to cracking during welding and the changes in mechanical properties of the welded joint area are used as the main indicators to evaluate the welding properties of materials. So the higher the carbon content, the poorer the welding properties.

Low carbon steel and low alloy steel with carbon content less than 0.25% have excellent plasticity and impact toughness, and the plasticity and impact toughness of welded joints after welding are also good. When welding, preheating and post weld heat treatment are not required, and the welding process is easy to control, so it has good welding properties.

In addition, the smelting and rolling state, heat treatment state, and micro structure state of steel all affect the welding properties to varying degrees. Improving the welding properties of steel through refining, refining, refining grain size, and controlled rolling processes.

Welding materials directly participate in a series of chemical metallurgical reactions during the welding process, which determine the composition, structure, properties, and defect formation of the weld metal. If the welding material is chosen improperly and does not match the base material, not only will it not be possible to obtain a joint that meets the requirements for use, but it will also introduce defects such as cracks and changes in the micro structure and properties. Therefore, the correct selection of welding materials is an important factor in ensuring the acquisition of high-quality welding joints.

Process factors include welding methods, welding process parameters, welding sequence, preheating, post heating, and post weld heat treatment. Welding methods have a significant impact on welding properties, mainly manifested in two aspects: heat source characteristics and protection conditions.

Different welding methods have significant differences in heat sources in terms of power, energy density, and maximum heating temperature. Metal welding under different heat sources will exhibit different welding performance.

If the power of electroslag welding is high, but the energy density is low, the maximum heating temperature is not high, the heating is slow during welding, and the high temperature residence time is long, resulting in coarse grains in the heat affected zone and a significant decrease in impact toughness. It must be normalized to improve.

On the contrary, methods such as electron beam welding and laser welding have low power but high energy density and rapid heating. The high temperature residence time is short, the heat affected zone is narrow, and there is no danger of grain growth.

By adjusting the welding process parameters and adopting other process measures such as preheating, post heating, multi-layer welding, and controlling inter layer temperature, the welding thermal cycle can be adjusted and controlled, thereby changing the welding properties of the metal. If measures such as preheating before welding or heat treatment after welding are taken, it is entirely possible to obtain welded joints without crack defects and meeting the performance requirements.

It mainly refers to the design form of welding structures and welding joints, such as the influence of factors such as structural shape, size, thickness, joint groove form, weld seam arrangement and cross-sectional shape on welding properties. Its impact is mainly manifested in the transfer of heat and the state of force.

The direction and heat transfer speed of different plate thicknesses, joint forms, or groove shapes are different, which affects the crystallization direction and grain growth of the melt pool. The switch of the structure, plate thickness, and arrangement of welds determine the stiffness and restraint of the joint, which affects the stress state of the joint.

Poor crystal morphology, severe stress concentration, and excessive welding stress are the basic conditions for forming welding cracks. Reducing the stiffness of joints, minimizing cross welds, and reducing various factors that cause stress concentration in design are important measures to improve welding properties.

It refers to the working temperature, load conditions, and working medium during the service period of welded structures. These working environments and operating conditions require welding structures to have corresponding performance.

Welding structures that work at low temperatures must have anti brittle fracture performance. Structures working at high temperatures should have creep resistance. Structures working under alternating loads have good fatigue resistance.

Welding containers working in acidic, alkaline, or salt media should have high corrosion resistance, etc. In short, the more stringent the usage conditions, the higher the quality requirements for welded joints, and the more difficult it is to ensure the metal welding properties of the material.

The metal welding properties are multifaceted, and the thermal, mechanical and chemical properties of metals need to be considered during welding. By understanding these characteristics, appropriate welding processes, welding materials and equipment can be selected to ensure a smooth welding process and obtain high-quality welded joints. In practical applications, controlling welding heat input and selecting the correct welding methods and materials are essential to avoid welding defects and improve joint strength and durability.

Click here to more about: Performance Characteristics And Functions Of Sheet Metal Welding Production Line