The punching process of metal sheets is a manufacturing method that uses a punching machine or CNC punching machine to punch holes of various shapes on metal sheets. The key steps of the sheet metal punching process include mold design, material preparation, punching equipment, punching process, edge processing, etc. The metal punching process is often used to manufacture filter screens, ventilated panels, decorative building panels, automotive parts, etc.

The punching process of metal sheets is a manufacturing method that uses a punching machine or CNC punching machine to punch holes of various shapes on metal sheets. This process is widely used in industries such as automobiles, construction, and home appliances to manufacture metal products that require ventilation, decoration, drainage, or weight reduction.

The punching process of metal sheets can be divided into several key steps, each of which is crucial to the quality of the final product. The following is a detailed analysis of the key steps of the punching process.

The die is the core of the sheet metal punching process and determines the shape, size, arrangement and quality of the hole. According to the required hole shape, a single punch die, a compound die or a step die can be designed.

The die is installed on the punch press and fixed between the upper and lower die seats of the punch press. The precision and durability of the die directly affect the punching effect.

- Punch: Located in the upper die seat, it forms the shape of the punched hole and is responsible for the actual punching operation.

- Die: Located in the lower die seat, corresponding to the position of the punch, supports the sheet and withstands the punching force.

Die design is one of the core steps of the punching process and determines the shape, size and arrangement of the hole. The die is usually made of high-hardness materials (such as high-speed steel or cemented carbide) to ensure that it can withstand high-intensity punching pressure during the punching process.

- Hole shape: Common shapes include round, square, oval, hexagonal, etc.

- Arrangement: The holes can be arranged in a regular array, randomly, or in a specific pattern designed according to functional requirements.

- Tolerance requirements: The machining accuracy of the mold needs to be considered to ensure that the location and size of the holes meet the design standards.

- Single punch: Only one hole is punched each time.

- Compound mold: Multiple holes can be punched at the same time in one punching operation.

- Progressive die: A combination of punching and other processes can be completed at multiple stations.

The selection of punching materials directly affects the smooth progress of the punching process and the quality of the final product. Different metal materials are selected according to the purpose and design requirements of the product, such as aluminum, copper, stainless steel, cold-rolled steel, etc.

In the sheet metal punching process, the metal sheet must be selected and prepared first. The choice of materials depends on the purpose, mechanical performance requirements, appearance requirements, etc. of the final product.

- Aluminum sheet: light weight, corrosion resistance, suitable for electronic product housing, decorative building materials.

- Stainless steel sheet: high strength, corrosion resistance, suitable for mechanical parts, automotive parts, etc.

- Cold-rolled steel sheet: easy to process, suitable for electrical equipment housing, industrial manufacturing, etc.

- Thickness: The thickness of the sheet will affect the difficulty of punching. Thicker sheets require greater punching force, which may affect the life of the mold.

- Hardness: Harder materials, such as stainless steel, have higher requirements for the mold when punching and may cause greater wear.

- Surface treatment: Some metal sheets may be treated before punching, such as galvanizing, coating, etc., to improve corrosion resistance or aesthetic effect.

The thickness, hardness and surface treatment of the sheet will also affect the punching process. For example, thicker metal sheets require greater punching force, and harder materials (such as stainless steel) will cause greater wear on the die.

Common punching equipment can be roughly divided into 7 categories according to its operation mode, applicable materials and processing accuracy. Each equipment has its specific application scenarios and characteristics, suitable for different punching needs. Which equipment to choose depends on the complexity, batch and precision requirements of the product. The following are several common punching equipment:

Mechanical punching machine is a traditional punching equipment that relies on a motor to drive a crankshaft or connecting rod mechanism to generate punching force. It is suitable for large-scale and relatively simple punching operations.

Store kinetic energy through the flywheel, release kinetic energy quickly when needed, push the punch with extremely high speed and force to complete the punching of metal sheets.

Suitable for mass production and high efficiency.

Simple structure and relatively convenient maintenance.

For products with complex hole shapes and high precision requirements, it has low applicability.

Poor adjustment flexibility, once the mold is determined, it is not easy to quickly change the punching pattern.

Application: Widely used in processing relatively simple parts, such as hardware, auto parts, etc.

CNC punching machine is the most common type of modern punching equipment. It adopts computer numerical control technology and is suitable for processing complex patterns and high-precision hole shapes. It controls the movement and position of the punch through the program, and can flexibly complete a variety of punching tasks.

The punch movement and punching process of the punching machine are controlled by programming. The plate is fixed on the CNC machine tool, and the equipment automatically processes according to the preset drawings.

Suitable for processing complex graphics and strong flexibility.

High processing accuracy, the punching position and shape can be quickly adjusted according to needs.

High degree of automation, reduced manual intervention, and high production efficiency.

High cost, suitable for small and medium batch production.

Maintenance is more complicated and requires professional technicians to operate and maintain.

Application: Commonly used in metal doors and windows, decorative panels, filters and other products that require high precision and complex patterns.

Hydraulic punching machine uses hydraulic system to provide punching force, which is suitable for processing thick metal plates. Unlike mechanical punching machines, hydraulic punching machines can produce punching force steadily and continuously, which is suitable for processing metal materials of larger size or thickness.

The punch is driven by a hydraulic cylinder, hydraulic oil is used as the transmission medium, and continuous pressure is provided by a hydraulic pump.

The pressure is stable, suitable for processing thick plates and large-sized metal plates.

The punching force can be flexibly adjusted to adapt to plates of different thicknesses and materials.

The noise is relatively low and the operation is relatively safe.

The maintenance of the hydraulic system is more complicated, and hydraulic oil, pipelines and other components need to be checked regularly.

The processing speed is relatively slow, which is suitable for small and medium-sized batch processing tasks.

Application: Used for processing relatively large metal punching products such as thick plates, structural parts, and automotive parts.

The turret punching machine is an efficient CNC punching machine. Its punch is installed on the turret, which can automatically rotate and replace different punches to complete punching of different shapes. It is usually used in large-scale and diversified hole production occasions.

The turret is equipped with multiple punches of different shapes and sizes. The machine automatically switches the punches according to the programming to perform punching operations of different shapes.

The punches can be switched quickly, suitable for processing holes of various shapes.

High production efficiency, suitable for mass production.

High degree of automation, reducing manual operation time.

The turret punch press is expensive and the equipment is complex.

The punching force is relatively small, suitable for processing thinner plates.

Application: Suitable for high-demand punching processing, such as ventilation mesh plates, electronic component housings, sheet metal processing, etc.

The laser metal punching machine is a device that melts and vaporizes metal materials through high-energy laser beams to achieve precision punching. The laser punching machine can process extremely complex hole shapes and can achieve high-precision holes on thicker metal sheets.

Through the concentrated irradiation of high-energy laser beams, the metal is instantly melted or vaporized locally to form holes.

Extremely high precision, suitable for processing micropores and complex shapes.

Non-contact processing reduces mold wear and replacement.

It can process extremely hard materials and thicker metal plates.

High cost and large equipment investment.

The laser processing speed is relatively slow and is suitable for small batch and precision processing.

Application: Used for high-precision and high-demand metal punching, such as aerospace parts, electronic product housings, medical devices, etc.

Pneumatic punching machine uses compressed air to drive the punch, which is suitable for punching operations of light and thin metal sheets. Pneumatic punching machine has a fast punching speed and is widely used in light industry and electronic industry.

The compressed air is converted into mechanical energy through the cylinder to drive the punch for punching.

Simple operation, fast punching speed, suitable for light industrial applications.

The equipment structure is relatively simple and easy to maintain.

Suitable for mass production and low equipment cost.

Limited punching force, suitable for processing thinner materials.

Noise is high and silencer is required.

Application: Widely used in electronic components, small hardware, household appliances and other fields.

Electric punching machine is similar to mechanical punching machine, but uses electric motor to directly drive the punch for punching. It is often used for small punching operations and is suitable for light industrial processing of small and medium-sized enterprises.

The punch is directly driven by the electric motor to provide continuous punching force.

Easy to operate and suitable for small batch production.

Low cost, suitable for small enterprises.

The noise is relatively low and the operation is flexible.

The punching force is small and it is not suitable for the processing of thick plates or high-strength materials.

The degree of automation is low and requires more manual participation.

Application: used to manufacture small metal parts, light sheet metal parts, etc.

Different sheet metal punching equipment has its own advantages and disadvantages and applicable scenarios. Mechanical punching machines are suitable for large-scale simple punching, CNC punching machines and turret punching machines are suitable for punching with complex patterns and high-precision requirements, hydraulic punching machines are suitable for thick plate processing, and laser punching machines are suitable for micro-hole processing with high precision and complex shapes. When selecting equipment, it is necessary to comprehensively consider the specific processing requirements, material properties and production scale.

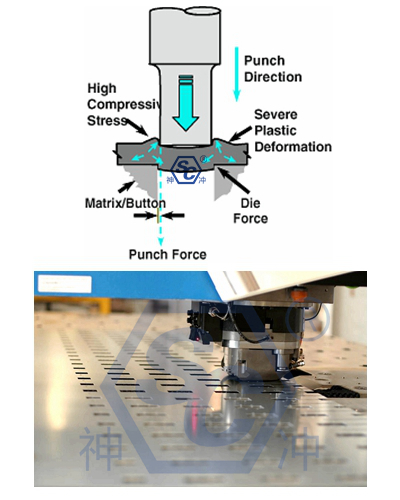

During the punching process of metal sheets, there is a certain gap between the punch and the die of the die, which is called the blanking gap. Whether the blanking gap is designed reasonably directly affects the quality of punching and the life of the die.

- Reasonable gap: ensure smooth hole edges, reduce burrs, and ensure mold durability.

- Too large a gap: large burrs will be generated on the edge of the hole, reducing precision.

- Too small a gap: the die wears faster, and cracks or irregular hole shapes may occur during punching.

Usually, the design of the blanking gap depends on the thickness and material of the sheet, which is generally 5%-10% of the sheet thickness.

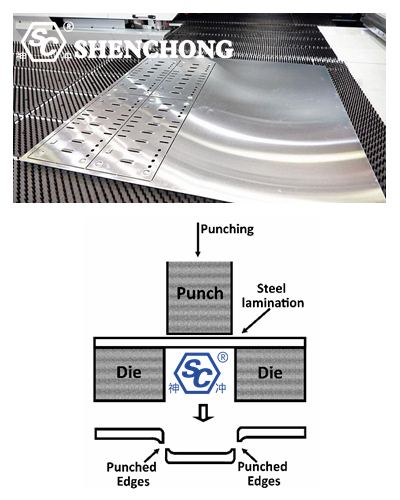

The actual operation of punching is to place the metal sheet in the die, apply pressure through the punching equipment, and the punch will partially cut and penetrate the metal sheet to form a hole.

- Fix the sheet: Fix the metal sheet on the die so that it will not slide during the punching process.

- Punch down: The punch of the punch press penetrates the sheet under the action of a driving force (mechanical, hydraulic or pneumatic, etc.). According to the shape of the die, a specific hole shape is formed.

- Waste discharge: The punch pushes the waste of the sheet into the die, the waste is discharged, and the punching process is completed.

- Punching pressure: Set according to the thickness and hardness of the sheet. Excessive pressure will cause the sheet to deform, and too little pressure will prevent the hole from being completely punched out.

- Punching speed: A faster punching speed helps improve production efficiency, but too fast may cause increased die wear or quality problems.

- Lubrication and cooling: During the punching process, the friction and heat generated between the die and the sheet need to be controlled by lubricating oil or coolant to reduce die wear and improve processing accuracy.

After punching, burrs (i.e. small uneven metal debris) may appear on the edge of the hole. Deburring and surface treatment can improve the aesthetics and functionality of the hole.

After punching, burrs or irregularities may appear on the edge of the metal hole. Depending on the precision and appearance requirements of the product, post-treatment may be required to ensure smooth edges of the hole.

- Deburring: Remove burrs from the edge of the hole by mechanical deburring, chemical deburring or laser deburring.

- Surface treatment: As needed, the metal sheet after punching can be further surface treated, such as polishing, painting, electroplating, etc., to increase corrosion resistance, enhance aesthetics or impart specific functionality.

- Polishing: In situations where high surface finish is required, polishing is used to improve the appearance and feel of the hole.

The punched products usually need to undergo quality inspection to ensure that the size, position and shape of the holes meet the design requirements, and check whether there are obvious defects on the surface.

- Measuring instruments: Use precision measuring tools (such as calipers, micrometers, etc.) to measure the size of the holes.

- Visual inspection: Check the surface quality and position accuracy of the holes by naked eyes or automatic inspection equipment.

- Mechanical testing: For products with strength requirements, tensile or compressive tests can be performed to ensure the reliability of the products in use.

Depending on the specific application requirements, the punched sheet may need to be further processed or treated, for example:

The punched metal sheet may need to be formed by bending equipment to meet structural requirements.

Multiple punched parts may need to be welded together to form a larger structure or component.

In order to increase corrosion resistance or aesthetics, the punched sheet can be surface treated, such as spraying, galvanizing, anodizing, etc.

The waste generated during the punching process (usually the metal in the punched hole part) needs to be cleaned and recycled in time. Waste can be recycled, especially high-value metal materials (such as stainless steel, aluminum), which can be regenerated into new materials through smelting.

After the punching process is completed, the metal sheet can be subsequently bent, welded or assembled according to design requirements. Depending on the purpose of the punching, the product can be used to manufacture screens, ventilation equipment, decorative building materials, automotive parts, etc.

Each step of the punching process requires strict control and high-quality equipment support, especially in high-precision and mass production, mold design, material selection and equipment configuration are key factors to ensure punching quality.

The metal punching process is an efficient and precise processing method that is widely used in the manufacturing industry. It can process holes of different shapes on various metal sheets and has the following main advantages and features:

The metal punching process can produce holes of the same specifications in large quantities in a short time, especially when using automated equipment such as CNC metal plate punching machines or turret punch presss, the production efficiency is higher. For parts that require a large amount of punching, the punching process can significantly increase output and reduce production cycle time.

The sheet metal punching process can achieve high-precision hole shape and position with the help of precise design of the mold. Especially when using a CNC punch machine, it can easily ensure the consistency of hole diameter, hole spacing and hole shape. Even complex patterns and diverse hole shapes can be accurately realized through the punching process.

The metal punching process is suitable for a variety of metal materials, including:

- Stainless steel: corrosion-resistant and high strength.

- Aluminum alloy: light weight and easy to process.

- Cold rolled steel plate: Affordable and easy to form.

There are also conductive materials such as copper and brass. This process can handle almost all kinds of metal plates from thin plates to thick plates, and has strong adaptability.

Through appropriate die design, the punching process can form holes of various shapes on metal plates, such as round, square, oval, hexagonal, etc. In addition, complex patterns and combined hole shapes can also be achieved through step punching or composite die, which has extremely high flexibility.

Compared with other metal processing methods such as laser cutting or water cutting, the equipment cost of the punching process is relatively low, especially in mass production, the processing cost of each hole will be further reduced. The punching process is suitable for mass and standardized production, and the mold is highly reusable, which greatly reduces the processing cost of each piece.

Modern punching equipment, especially CNC sheet metal punching machines, turret punching machines, etc., can realize automatic operation. Through programming control, the punching pattern and position can be quickly adjusted, which reduces the error of manual operation and improves production efficiency. Automated equipment can also quickly switch molds to adapt to diversified product needs.

Since the punching process relies on mold processing, the results of each punching are consistent, which ensures that the parts produced in batches are highly consistent in size, shape and quality. Especially in the automotive, electronics, construction and other industries, the consistency of parts is extremely important, and the punching process can meet this demand well.

Compared with laser cutting, sheet metal punching requires lower energy consumption. Mechanical punching machines, pneumatic punching machines and other equipment consume less electricity or gas source when working, so they can effectively reduce energy consumption in large-scale production.

The punching process in metal sheets has a high material utilization rate, and usually minimizes material waste through reasonable layout and mold design. At the same time, the waste generated by punching (such as cut metal fragments) can be recycled and reused, reducing the impact on the environment.

After long-term application and development, the metal sheets punching process has become very mature, and the mold design and equipment operation are also very standardized. This process has strong stability and can be produced continuously for a long time without large quality fluctuations.

The metal punching process has become an indispensable and important processing method in industrial manufacturing with its high efficiency, precision, low cost and wide applicability. Especially in mass production, it can provide excellent production efficiency and product consistency, meeting a variety of needs from simple parts to complex structures.

Metal punching technology is widely used in many industries due to its high efficiency, precision and diversity. The following are the main application areas of metal punching technology:

- Building curtain wall: Perforated metal plates are widely used in the decoration of modern building exterior walls, providing aesthetics and ventilation effects while protecting buildings.

- Metal ceilings and partitions: Perforated ceilings, partition walls and decorative metal plates are used in interior design, which not only enhances the visual effect, but also has functions such as breathability and sound absorption.

- Guardrails and fences: Perforated metal plates are often used to make construction site guardrails, window guards, balcony fences, etc., which are both safe and beautiful.

- Automobile parts: A large number of punching processes are used in automobile bodies, chassis, exhaust pipes and other parts, mainly for weight reduction, heat dissipation and drainage capabilities.

- Radiators and filters: Metal radiators and filters made by punching technology are often used in engines and air conditioning systems, which help optimize ventilation and cooling.

- Home appliances: The housings and ventilation panels of home appliances such as refrigerators, washing machines, and microwave ovens are largely made of metal perforated plates, which not only improves heat dissipation performance but also meets aesthetic requirements.

- Electronic equipment housings: Perforated plates are used on the housings of electronic products such as computer cases and server cabinets to improve heat dissipation and protect internal components.

- Circuit board brackets: Perforated metal plates are used to fix and support electronic circuit boards to ensure stability and ventilation.

- Office furniture: The supporting structures in furniture such as office chairs, desktop brackets, and bookshelves are usually made of perforated metal plates, which not only ensures firmness but also reduces material weight.

- Decorative furniture: Perforated metal plates are used in decorative furniture design for chair backs, lampshades, cabinet doors, etc., adding a modern feel to home or office space.

- Air conditioning ventilation system: Metal perforated plates are used in vents, air filters, and other parts to help air circulation and keep the environment comfortable.

- Filters and screens: Perforated plates used in liquid and gas filters can control the amount of particles passing through, and are widely used in environmental protection equipment, food processing, medical equipment, etc.

- Machine shields: In industrial equipment, perforated metal shields protect operators from moving parts while ensuring ventilation and heat dissipation of equipment.

- Equipment brackets and fixings: The punching process can produce equipment brackets, hooks and other fixings, which are widely used in industrial production lines and workshop equipment installation.

- Weight reduction design: Aircraft parts, such as wing internal structures, seat supports, etc., often use perforated metal plates to reduce weight while ensuring sufficient strength and safety.

- Sound insulation and ventilation structure: In aerospace, perforated plates are used in aircraft cabins, engine hoods and other parts to help sound insulation, ventilation and noise reduction.

- Sound barriers: Along highways and railways, perforated metal plates are used to make sound barriers, which effectively absorb and attenuate noise through their structures to ensure the quietness of the surrounding environment.

- Traffic signs and guardrails: Metal perforated plates are widely used to make road signs, guardrails and bridge structures to enhance their strength and protective effect.

- Medical device shells: Perforated metal plates are used to manufacture the shells of medical equipment to ensure heat dissipation and hygiene inside the equipment.

- Operating table and bed brackets: Many hospitals use equipment brackets made of perforated metal plates, which are both sturdy and easy to clean.

- Screens and filtering equipment: Perforated metal plates are widely used for cleaning and sorting crops after harvest, as well as feed screening equipment in animal husbandry.

- Livestock farm facilities: Perforated metal plates are also used for ventilation devices and fences for livestock breeding, which helps to keep the environment ventilated and hygienic.

- Filtration and purification equipment: Perforated plates are widely used in environmental protection equipment such as water treatment, air purification, and exhaust gas treatment, as filters or heat dissipation elements to control the passage of pollutant particles.

- Noise reduction equipment: Perforated plates are often used in industrial environments as noise reduction devices for soundproof walls or equipment, effectively reducing noise pollution.

Sheet metal punching technology is widely used, covering a variety of industries from architectural decoration, automobile manufacturing, household appliances, industrial equipment, transportation facilities, medical equipment to environmental protection equipment. It meets various structural and functional requirements through precise processing, flexible design and efficient production methods, and has become an indispensable and important processing technology in modern industrial manufacturing.